Izimiso eziyisisekelo ze-PCB pad design

Ngokusho kokuhlaziywa kwesakhiwo esihlanganyelwe se-solder sezingxenye ezihlukahlukene, ukuze kuhlangatshezwane nezidingo zokuthembeka kwamalunga e-solder, idizayini yephedi ye-PCB kufanele ibe yizici ezilandelayo ezibalulekile:

I-1, i-symmetry: zombili iziphetho zephedi kufanele zibe symmetrical, ukuze kuqinisekiswe ibhalansi ye-molt solder surface tension.

2. Isikhala sephedi: Qinisekisa usayizi wethanga ofanele wesiphetho sengxenye noma iphinikhodi nephedi.Isikhala sephedi esikhulu kakhulu noma esincane kakhulu sizodala izinkinga zokushisela.

3. Usayizi osele wephedi: ubukhulu obusele bokuphela kwengxenye noma iphinikhodi ngemva kokuxhuma ngephedi kufanele kuqinisekiswe ukuthi i-solder joint ingaba i-meniscus.

4.Ububanzi bephedi: Kufanele buhambisane ngokuyisisekelo nobubanzi besiphetho noma iphinikhodi yengxenye.

Izinkinga ze-solderability ezibangelwa ukukhubazeka kokuklama

01. Usayizi wephedi uyahlukahluka

Usayizi wedizayini yephedi udinga ukuhambisana, ubude bufanele bufanele ububanzi, ubude besandiso sephedi bunobubanzi obufanelekile, bufushane kakhulu noma bude kakhulu bathambekele kusenzeko se-stele.Ubukhulu bephedi abuhambisani futhi ukungezwani akulingani.

02. Ububanzi bephedi bukhulu kunephinikhodi yedivayisi

Idizayini yephedi ayikwazi ukuba banzi kakhulu kunezingxenye, ububanzi bephedi buyi-2mil ububanzi kunezingxenye.Ububanzi bephedi obubanzi kakhulu buzoholela ekususweni kwengxenye, ekushiseleleni komoya kanye nethini elinganele kuphedi nezinye izinkinga.

03. Ububanzi bephedi buncane kunephinikhodi yedivayisi

Ububanzi bomklamo wephedi buncane kunobubanzi bezingxenye, futhi indawo yokuthintana kwephedi nezingxenye incane uma amapheshana e-SMT, okulula ukubangela ukuthi izingxenye zime noma ziphenduke.

04. Ubude bephedi bude kunephinikhodi yocingo

Iphedi elakhiwe akufanele libe lide kakhulu kunephini lengxenye.Ngalé kobubanzi obuthile, ukugeleza kwe-flux okweqile phakathi ne-SMT reflow welding kuzobangela ingxenye ukuthi idonsele indawo ye-offset ohlangothini olulodwa.

05. Isikhala phakathi kwamaphedi sifushane kunaleso sezakhi

Inkinga yesifunda esifushane yesikhala sephedi ngokuvamile yenzeka kusikhala sephedi ye-IC, kodwa idizayini yesikhala yangaphakathi yamanye amaphedi ayikwazi ukuba mfushane kakhulu kunezikhala zephinikhodi yezingxenye, okuzodala ukujikeleza okufushane uma kweqa uhla oluthile lwamanani.

06. Ububanzi bephinikhodi yephedi buncane kakhulu

Kupeshi ye-SMT yengxenye efanayo, amaphutha kuphedi kuzobangela ingxenye ukuthi iphume.Isibonelo, uma iphedi iyingcosana kakhulu noma ingxenye yephedi incane kakhulu, ngeke yakhe ithini noma ithini elincane, okuholela ekucindezelekeni okuhlukile kuzo zombili iziphetho.

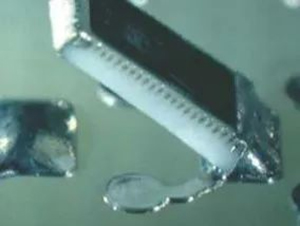

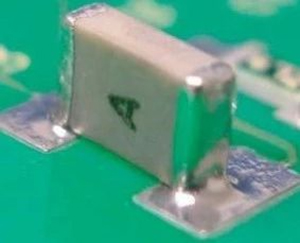

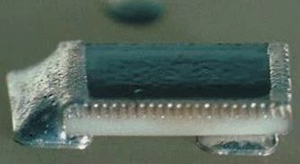

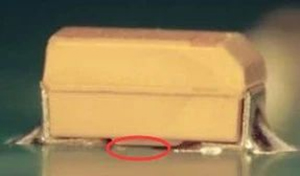

Izimo zangempela zamaphedi amancane okuchema

Usayizi wamaphedi wezinto ezibonakalayo awufani nosayizi wephakheji ye-PCB

Incazelo yenkinga:Uma umkhiqizo othile ukhiqizwa ku-SMT, kutholakala ukuthi i-inductance isusiwe ngesikhathi sokuhlolwa kwe-welding yangemuva.Ngemuva kokuqinisekisa, kutholakala ukuthi impahla ye-inductor ayifani namaphedi.*1.6mm, impahla izobuyiselwa emuva ngemuva kokushisela.

Umthelela:Ukuxhunywa kukagesi kwezinto ezibonakalayo kuba buthakathaka, kuthinta ukusebenza komkhiqizo, futhi kubangela ngokujulile ukuthi umkhiqizo ungakwazi ukuqala ngendlela evamile;

Ukunwetshwa kwenkinga:Uma ingenakuthengwa ngobukhulu obufanayo ne-PCB pad, inzwa kanye nokumelana kwamanje kungahlangabezana nezinto ezidingwa umjikelezo, khona-ke ingozi yokushintsha ibhodi.

Isikhathi sokuthumela: Apr-17-2023