[Impahla eyomile] Izingcezu zeziqephu ze-SMT zokuhlukaniswa kwe-tin nokunamathisela ezicutshungulwayo, kungakanani ozaziyo?(2023 Essence), ukufanele!

Izinhlobo eziningi zezinto zokusetshenziswa zokukhiqiza zisetshenziswa ekucubunguleni isichibi se-SMT.I-tinnote iyona ebaluleke kakhulu.Izinga lokunamathisela ithini lizothinta ngqo ikhwalithi yokushisela yokucubungula isichibi se-SMT.Khetha izinhlobo ezahlukene zama-tinnuts.Ake ngethule kafushane ukuhlukaniswa okujwayelekile kwe-tin paste:

I-Weld paste iwuhlobo lwe-pulp yokuxuba impushana yokushisela ne-agent yokushisela efana ne-paste (i-rosin, i-diluent, stabilizer, njll.) ngomsebenzi oshiselwe.Ngokwesisindo, ama-80 ~ 90% angama-alloys ensimbi.Ngokwevolumu, insimbi ne-solder kubalwe ku-50%.

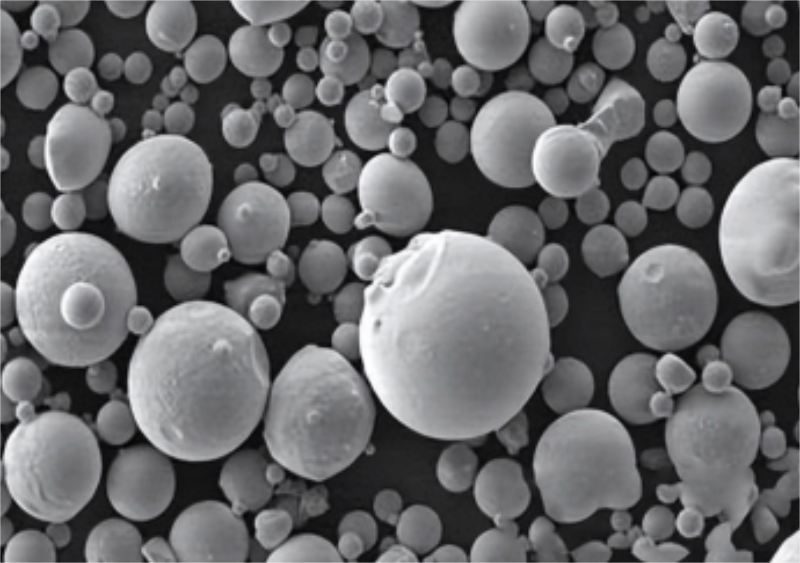

Umfanekiso 3 Ama-granules ayishumi (SEM) (kwesokunxele)

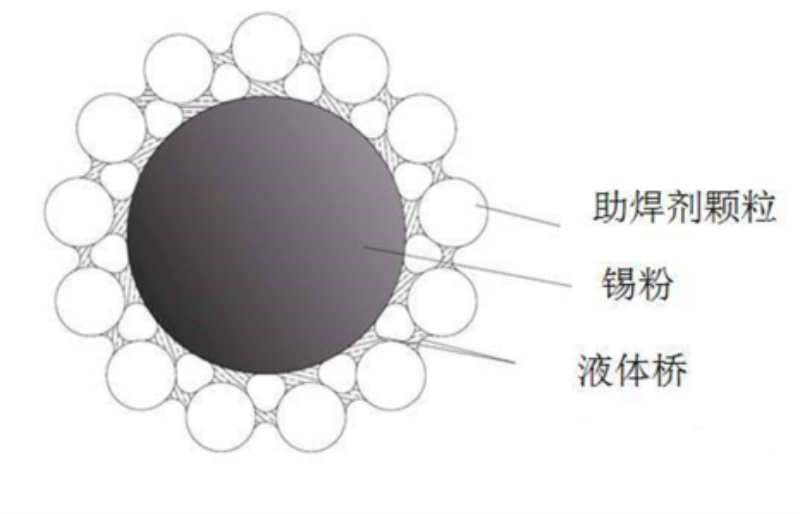

Umfanekiso 4 Umdwebo othize wekhava ye-tin powder (kwesokudla)

I-solder paste ithwala izinhlayiya ze-tin powder.Ihlinzeka ngokuwohloka kokugeleza okufanele kakhulu kanye nomswakama ukuze kuthuthukiswe ukudluliswa kokushisa endaweni ye-SMT futhi kunciphise ukushuba kwesimo samanzi ku-weld.Izithako ezahlukene zibonisa imisebenzi ehlukene:

① Ukuncibilika:

I-solvent yalesi sithako se-weld ye-ingredient inokulungiswa okufanayo kokulungiswa okuzenzakalelayo kwinqubo yokusebenza ye-tin paste, enomthelela omkhulu empilweni ye-weld paste.

② I-resin:

Idlala indima ebalulekile ekwandiseni ukunamathela kokunamathisela ithini kanye nokulungisa nokuvimbela i-PCB ekufakweni kabusha kwe-oxidation ngemva kokushisela.Lesi sithako esiyisisekelo sinendima ebalulekile ekulungiseni izingxenye.

③ I-activant:

Idlala indima yokususa izinto ezine-oxidized ze-PCB yethusi ungqimba lwangaphezulu lwefilimu kanye nengxenye yesayithi lesichibi se-SMT, futhi inomphumela wokunciphisa ukushuba kwesimo se-tin noketshezi lomthofu.

④ Itende:

Ukulungiswa okuzenzakalelayo kwe-viscosity ye-weld paste kudlala indima ebalulekile ekunyatheliseni ukuvimbela umsila nokunamathela.

Okokuqala, ngokusho kokwakheka kokuhlukaniswa kwe-solder paste

I-1, i-lead solder paste: iqukethe izingxenye zomthofu, ukulimala okukhulu emvelweni nasemzimbeni womuntu, kepha umphumela wokushisela muhle, futhi izindleko ziphansi, zingasetshenziswa kweminye imikhiqizo ye-elekthronikhi ngaphandle kwezidingo zokuvikela imvelo.

2, unamathisele we-solder ongenamthofu: izithako ezihambisana nemvelo, ukulimala okuncane, ezisetshenziswa emikhiqizweni ye-elekthronikhi enobungani bemvelo, ngokuthuthukiswa kwezidingo zemvelo kazwelonke, ubuchwepheshe obungenamthofu embonini yokucubungula i-smt buzoba umkhuba.

Okwesibili, ngokusho kwephuzu lokuncibilika lokuhlukaniswa kwe-solder paste

Ngokuvamile, indawo yokuncibilika ye-solder paste ingahlukaniswa ngokushisa okuphezulu, izinga lokushisa eliphakathi nendawo kanye nezinga lokushisa eliphansi.

Izinga lokushisa eliphakeme elivame ukusetshenziswa yi-Sn-Ag-Cu 305,0307;I-Sn-Bi-Ag itholwe ezingeni lokushisa eliphakathi nendawo.I-Sn-Bi ivame ukusetshenziswa emazingeni okushisa aphansi.Ekucubunguleni isichibi se-SMT kudingeka kukhethwe ngokuya nezici zomkhiqizo ezihlukene.

Okwesithathu, ngokusho kokuqina kwe-tin powder division

Ngokusho kobubanzi bezinhlayiya ze-tin powder, i-tin paste ingahlukaniswa ibe amamaki angu-1, 2, 3, 4, 5, 6 empushana, okuyi-3, 4, 5 powder isetshenziswa kakhulu.Umkhiqizo oyinkimbinkimbi kakhulu, ukukhethwa kwempushana kathini kudinga ukuba kuncane, kodwa i-tin powder encane, indawo ye-oxidation ehambisanayo ye-powder powder izokwanda, futhi i-tin powder eyindilinga isiza ukuthuthukisa ikhwalithi yokunyathelisa.

No. 3 powder: Intengo ishibhile, ivame ukusetshenziswa ezinqubweni ezinkulu ze-smt;

Inombolo ye-4 powder: evame ukusetshenziswa ku-tight foot IC, i-smt chip processing;

No. 5 powder: Ivamise ukusetshenziswa ezingxenyeni zokushisela ezinembe kakhulu, omakhalekhukhwini, amaphilisi neminye imikhiqizo edinga kakhulu;Uma unzima kakhulu umkhiqizo wokucubungula i-smt patch, kubaluleke kakhulu ukukhetha okunamathiselwe kwe-solder, futhi ukukhethwa kokunamathisela kwe-solder okufanelekile komkhiqizo kusiza ukuthuthukisa inqubo yokucubungula i-smt patch.