Ukunemba okuphezulu kwebhodi lesekethe ye-PCBA yepulaki ye-DIP ekhethiwe yokukhetha i-wave soldering design kufanele ilandele izidingo!

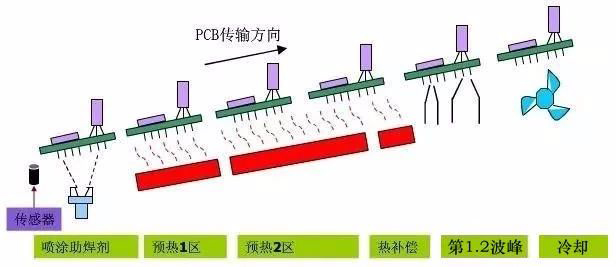

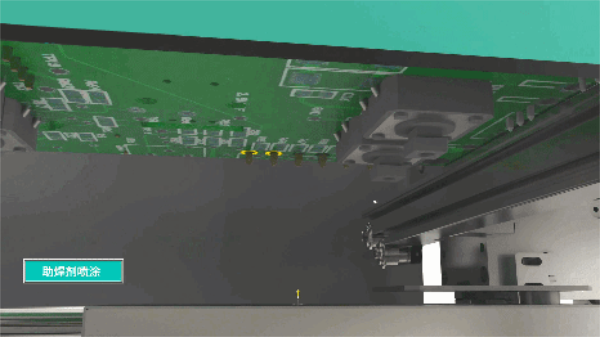

Enqubweni yendabuko yomhlangano we-elekthronikhi, ubuchwepheshe be-wave welding ngokuvamile busetshenziselwa ukushisela izingxenye zebhodi eziphrintiwe ezine-perforated insert elements (PTH).

I-DIP wave soldering inokungalungi okuningi:

1. Izingxenye ze-SMD ezinobukhulu obuphezulu, ze-fine-pitch azikwazi ukusatshalaliswa endaweni yokushisela;

2. Kunamabhuloho amaningi futhi ashodayo;

3.I-Flux idinga ukufuthwa;ibhodi eliphrintiwe lisontekile futhi likhubazekile ukushaqeka okukhulu okushisayo.

Njengoba ukuminyana komhlangano wesifunda wamanje kukhula ngokuya phezulu, akunakugwenywa ukuthi izingxenye ze-SMD ezinobukhulu obuphezulu, ne-fine-pitch zizosatshalaliswa endaweni ehlanganisiwe.Inqubo yendabuko ye-wave soldering ayinamandla okwenza lokhu.Ngokuvamile, izakhi ze-SMD endaweni ehlanganisiwe zingathengiswa kuphela ngokuhlukile., bese ulungisa ngesandla amajoyinti e-solder e-plug-in asele, kodwa kunenkinga yokungaguquguquki kwekhwalithi ye-solder engalungile.

Njengoba ukusoda kwezingxenye zembobo (ikakhulukazi umthamo omkhulu noma izingxenye zephimbo elihle) kuya kuba nzima nakakhulu, ikakhulukazi emikhiqizweni engenawo umthofu kanye nezidingo ezithembeke kakhulu, ikhwalithi yokudambisa yokunamathisela ngesandla ngeke isakwazi ukuhlangabezana nekhwalithi ephezulu. izinto zikagesi.Ngokwezidingo zokukhiqiza, i-wave soldering ayikwazi ukuhlangabezana ngokugcwele nokukhiqizwa kanye nokusetshenziswa kwamaqoqo amancane kanye nezinhlobonhlobo eziningi ekusetshenzisweni okukhethekile.Ukusetshenziswa kwe-wave soldering ekhethiwe kuye kwakhula ngokushesha eminyakeni yamuva.

Kumabhodi wesifunda we-PCBA anezingxenye ezinezimbobo ze-THT kuphela, ngoba ubuchwepheshe be-wave soldering buseyindlela yokucubungula ephumelela kakhulu okwamanje, akudingekile ukuthi kushintshwe i-wave soldering ngokukhetha okukhethekile, okubaluleke kakhulu.Kodwa-ke, i-soldering ekhethiwe ibalulekile kumabhodi obuchwepheshe obuxubile futhi, kuye ngokuthi hlobo luni lombhobho osetshenzisiwe, amasu okugcwalisa i-wave soldering angaphindwa ngendlela enhle.

Kunezinqubo ezimbili ezihlukene zokuhlanganisa okukhethiwe: ukudonsa ukudonsa kanye ne-dip soldering.

Inqubo ekhethiwe yokudonsa i-solder yenziwa nge-wave eyodwa ye-tip solder encane.Inqubo yokudonsa i-solder ifanele ukusoda ezindaweni eziqinile kakhulu ku-PCB.Isibonelo: amajoyinti e-solder noma izikhonkwane, umugqa owodwa wezikhonkwane ungahudulwa futhi udayiswe.

Ubuchwepheshe be-selective wave soldering ubuchwepheshe obusanda kuthuthukiswa kubuchwepheshe be-SMT, futhi ukubukeka kwabo kuhlangabezana kakhulu nezidingo zomhlangano wamabhodi e-PCB axubile aphezulu nahlukene.I-wave soldering ekhethiwe inezinzuzo zokusethwa okuzimele kwamapharamitha ahlangene e-solder, ukushaqeka okuncane okushisayo ku-PCB, isifutho esincane esishintshashintshayo, nokuthembeka okuqinile kwe-solder.Kancane kancane iba ubuchwepheshe obubalulekile bokuthengisa ama-PCB ayinkimbinkimbi.

Njengoba sonke sazi, isigaba sokuklama ibhodi lesifunda se-PCBA sinquma u-80% wezindleko zokukhiqiza umkhiqizo.Ngokufanayo, izici eziningi zekhwalithi zilungiswa ngesikhathi sokuklama.Ngakho-ke, kubaluleke kakhulu ukucabangela ngokugcwele izici zokukhiqiza kunqubo yokuklama ibhodi lesifunda se-PCB.

I-DFM enhle iyindlela ebalulekile yabakhiqizi bezingxenye ezifaka i-PCBA ukuze banciphise amaphutha okukhiqiza, benze lula inqubo yokukhiqiza, bafinyeze umjikelezo wokukhiqiza, banciphise izindleko zokukhiqiza, bathuthukise ukulawula kwekhwalithi, bathuthukise ukuncintisana kwemakethe yomkhiqizo, futhi bathuthukise ukwethembeka nokuhlala isikhathi eside komkhiqizo.Ingenza amabhizinisi akwazi ukuthola izinzuzo ezihamba phambili ngokutshalwa kwezimali okuncane futhi azuze umphumela ophindwe kabili ngomzamo oyingxenye.

Ukuthuthukiswa kwezingxenye zokukhweza phezulu kuze kube namuhla kudinga ukuthi onjiniyela be-SMT bangabi nekhono kubuchwepheshe bokuklama ibhodi lesifunda, kodwa futhi babe nokuqonda okujulile nolwazi olusebenzayo olucebile kubuchwepheshe be-SMT.Ngenxa yokuthi umklami ongaqondi izici zokugeleza kwe-solder paste kanye ne-solder ngokuvamile kunzima ukuqonda izizathu nemigomo yokubopha, i-tipping, i-tombstone, i-wicking, njll, futhi kunzima ukusebenza kanzima ukuklama iphethini yephedi ngokunengqondo.Kunzima ukubhekana nezinkinga ezihlukahlukene zokuklama ngokombono wokwenziwa kwedizayini, ukuqinisekiswa kokuhlolwa, kanye nokwehliswa kwezindleko nezindleko.Isixazululo esiklanywe kahle sizobiza izindleko eziningi zokukhiqiza nokuhlola uma i-DFM ne-DFT (i-design for detectability) impofu.