Ubudlelwano phakathi kwepuleti lendwangu le-PCB ne-EMC

Umhlahlandlela: Uma sikhuluma ngobunzima bokushintshwa kwamandla kagesi, inkinga yepuleti yendwangu ye-PCB ayinzima kakhulu, kodwa uma ufuna ukusetha ibhodi le-PCB elihle, ukunikezwa kwamandla okushintshayo kufanele kube enye yezinkinga (i-PCB design ayilungile, okungase kubangele kungakhathaliseki ukuthi ulungisa kanjani ukulungisa iphutha Amapharamitha alungisa iphutha lendwangu. Lokhu akusona i-alamu), ngoba kunezici eziningi ezicabangela amabhodi endwangu ye-PCB, njengokusebenza kukagesi, umzila wenqubo, izidingo zokuphepha, imiphumela ye-EMC, njll. Phakathi kwezici, ugesi uyisisekelo kakhulu, kodwa i-EMC inzima kakhulu ukuyithinta.Inqubekelaphambili yamaphrojekthi amaningi inkinga ye-EMC.Lesi sihloko sizokwabelana nawe ngobudlelwano phakathi kwebhodi lendwangu ye-PCB ne-EMC kusuka ezikhombisi-ndlela ezingama-22.

- Isekethe ephekiwe ingenza ngokuzolile isekethe ye-EMI yedizayini ye-PCB

Umthelela wesekethe ngenhla ku-EMC ungacatshangwa.Izihlungi zokuphela kokufaka zilapha;i-anti-strikes evimbela ukucindezela;ukumelana no-R102 womthelela wamanje (nokulahlekelwa kokunciphisa ukudluliselwa);I-Y capacitor ehlungwa ngokuhlunga;i-fuse ethinta ibhodi lesakhiwo sezokuphepha;yonke idivayisi lapha ibaluleke kakhulu.Kuyadingeka ukunambitha ngokucophelela imisebenzi nemisebenzi yedivayisi ngayinye.Lapho umjikelezo wokuklama uklanywa, ileveli ye-EMC enokhahlo ingumklamo ozolile futhi ozolile, njengokusetha amazinga amaningana okuhlunga, inombolo kanye nendawo yenombolo yama-Y capacitor.Ukukhethwa kosayizi wokuzwela kwamandla kagesi kuhlobene eduze nesidingo sethu se-EMC.Yamukela wonke umuntu ukuze nixoxe ngamasekhethi e-EMI abonakala elula engxenye ngayinye.

- 2.Circuit and EMC: (I-anti-gravity topology eyaziwa kakhulu, bona ukuthi yiziphi izindawo ezibalulekile kusekethe eziqukethe indlela ye-EMC)

Izingxenye ezimbalwa zesifunda esithombeni esingenhla: umthelela ku-EMC ubaluleke kakhulu (qaphela ukuthi ingxenye eluhlaza ayikho).Isibonelo, wonke umuntu uyazi ukuthi imisebe yemisebe ye-electromagnetic field iyindawo, kodwa isimiso esiyisisekelo siwukushintsha kokuguquguquka kazibuthe., Okungukuthi, isifunda sendandatho esihambisanayo kumjikelezo.

I-current ingakhiqiza insimu yamagnetic, ekhiqiza insimu yamagnetic ezinzile futhi ayikwazi ukuguqulwa endaweni kagesi.Insimu kagesi ingakhiqiza insimu kazibuthe.Ngakho-ke qiniseka ukuthi unaka lezo zindawo ezinesimo sokushintsha, okungukuthi, omunye womthombo we-EMC.Nansi enye yomthombo we-EMC (enye yazo lapha, yiqiniso, kuzoba nezinye izici kamuva), njengesekethe yomugqa wamachashazi kusekethe, okuwukuvulwa kweshubhu yokushintsha ukuvula ishubhu.Isekhethi ye-turbine evaliwe ayikwazi nje kuphela ukuthi isivinini sokushintsha sokushintsha singalungisa umthelela ku-EMC, kodwa indawo yomjikelezo womzila wendwangu nayo inomthelela obalulekile!Amanye amalophu amabili adonsa indandatho kanye nesekhethi yokulungisa kabusha, qala ngokuqonda kusenesikhathi, bese ukhuluma ngakho kamuva.

- Okwesithathu, ukuhlobana phakathi kwe-PCB design kanye ne-EMC

1. Umthelela weluphu ye-PCB ku-EMC ubaluleke kakhulu.Isibonelo, i-anti-main power ring circuit, uma inkulu kakhulu, imisebe izoba mpofu.

2. Umthelela wezintambo zokuhlunga, isihlungi sisetshenziselwa ukuhlunga ukuphazamisa, kodwa uma i-PCB inezintambo ezimbi, isihlungi singase silahlekelwe umphumela.

3. Izingxenye zesakhiwo, ukuklama okungewona kahle phansi kwe-radiator kuzothinta, inguqulo evikelekile yomhlabathi, njll.;

4. Ingxenye ebucayi iseduze kakhulu nomthombo wokuphazamiseka.Isibonelo, umjikelezo we-EMI useduze neshubhu lokushintsha, okuzoholela nakanjani ku-EMC embi futhi kudinga indawo ecacile yokuzihlukanisa.

5. I-RC idonsa isifunda.

6. I-Y capacitor isekelwe phansi futhi izintambo, futhi indawo ye-Y capacitor nayo ibalulekile.

Ake sinikeze isibonelo esincane ngezansi:

Njengoba kuboniswe emfanekisweni ongenhla, umzila wephinikhodi we-X -capacitor ucutshungulwa ngaphakathi.Ungafunda ukwenza ipulaki ye-capacitor pink ride (usebenzisa i-extrusion current).Ngale ndlela, umphumela wokuhlunga we-X capacitor ungafinyelela isimo esihle kakhulu.

- 4. Ukulungiselela idizayini ye-PCB: (Ukulungiselela kwanele, umklamo kuphela ongaklanywa isinyathelo ngesinyathelo ukugwema ukuketulwa komklamo)

Kukhona cishe izici zalezi zici ezilandelayo.Kucatshangwa ukuthi inqubo yokuklama izocatshangelwa.Konke okuqukethwe akuhlangene nezinye izifundo.Kumane kuyisifinyezo sokuhlangenwe nakho kwayo.

1. Ubukhulu besakhiwo sokubukeka, kufaka phakathi izimbobo zokubeka, ukugeleza kwe-air duct, amasokhethi okokufaka nokuphumayo, udinga ukufanisa uhlelo lwamakhasimende, futhi udinga ukuxhumana nekhasimende, elilinganiselwe phezulu.

2. Isitifiketi sokuphepha, iluphi uhlobo lokuqinisekiswa komkhiqizo, iziphi izindawo ezenza ukufakwa okuyisisekelo kanye nebanga lokukhuphuka, nokuthi kuqiniswe kuphi ukugquma nokushiya indawo.

3. Idizayini yokupakisha: Ingabe sikhona isikhathi esikhethekile, esifana nezingxenye ezenziwe ngokwezifiso zokulungiselela ukupakisha.

4. Ukukhethwa kwemizila yenqubo: ukukhethwa kwephaneli elilodwa lephaneli eliphindwe kabili, noma ibhodi elinezingqimba eziningi, ukuhlola okuphelele ngokomdwebo wesimiso nosayizi webhodi, izindleko nokunye ukuhlola okuphelele.

5. Ezinye izidingo ezikhethekile zamakhasimende.

Ubuciko besakhiwo buzovumelana nezimo.Imithetho yezokuphepha isalungisiwe.Iziphi izitifiketi ezenziwa, futhi yiziphi izindinganiso zokuphepha, kunjalo, kukhona nemithethonqubo yezokuphepha evamile kumazinga amaningi, kodwa kukhona neminye imikhiqizo ekhethekile njengokwelashwa.

Ukuze ukhazimule, abangani bonjiniyela omusha wezinga lokungena abaphazamisi.Nansi eminye imikhiqizo evamile evamile.Okulandelayo yizidingo zebhodi lendwangu ezifingqiwe yi-IEC60065.Engqondweni yemithetho yezokuphepha, udinga ukukhumbula.Uma uhlangabezana nemikhiqizo ethile, kufanele ubhekane nayo:

1. Ibanga lamaphedi amafuse okokufaka likhulu kuno-3.0mm.Ipuleti lendwangu langempela liku-3.5mm (umane ukhuphuke ibanga lokukhuphuka kwamandla ngo-3.5mm ngaphambi kwefuse, bese ukhuphuka amandla ngo-3.0mm).

2. Imithetho yezokuphepha ngaphambi nangemuva kwebhuloho lokulungisa idingeka ukuthi ibe ngu-2.0mm, futhi ipuleti lendwangu libe ngu-2.5mm.

3. Ngemva kokulungiswa, imithetho yezokuphepha ngokuvamile ayidingi izidingo, kodwa igumbi lamandla kagesi aphezulu neliphansi lishiywa ngokuvumelana nogesi wangempela, futhi umkhuba wama-400V ungaphezu kuka-2.0mm.

4. Imithetho yezokuphepha yezinga lokuqala ingu-6.4mm (igebe likagesi), futhi ibanga lokukhuphuka lingcono kakhulu lisekelwe ku-7.6mm (qaphela: lokhu kuhlobene ne-voltage yangempela yokufaka. vumela) .

5. Sebenzisa izindawo ezibandayo esigabeni sokuqala futhi ukhombe ngokucacile;I-L, N, ilogo yokufaka ye-AC, ilogo yesixwayiso se-fuse, njll. konke kumele kumakwe ngokucacile.

Wonke umuntu unokungabaza ngalokhu okungenhla, angaxoxa futhi afunde komunye nomunye.

Nakulokhu, ibanga langempela lokuvikeleka lihlobene ne-voltage yangempela yokufaka nendawo yokusebenza.Ukubalwa okuqondile kwethebula kuyadingeka.Idatha inikezwa ukuze kusetshenziswe ireferensi kuphela futhi izikhathi zangempela zingaphansi kwezehlakalo zangempela.

- 5. Imithetho yokuphepha yedizayini ye-PCB icabangela ezinye izici

1. Qonda ukuthi ikuphi ukuqinisekiswa kwemikhiqizo yakho, hlobo luni lwemikhiqizo okungeyakho, njengezokwelapha, ukuxhumana, ugesi, i-TV, njll., kodwa ziningi izindawo ezifanayo.

2. Indawo lapho isivikelo siseduze nebhodi lendwangu ye-PCB, qonda izici zokwahlukanisa, okuyi-insulation eyisisekelo, okuyi-insulation ethuthukisiwe, kanye namabanga ahlukene ahlukene wokwahlukanisa.Kungcono ukuhlola izinga, futhi ibanga likagesi libalwa futhi ibanga liyakhuphuka.

3. Gxila kudivayisi yezokuphepha yomkhiqizo, njengobudlelwano phakathi kwe-transformer magnetism kanye nephini lomngcele wangempela.

4. Isitsha sokushisa kanye nebanga le-peripheral, umhlaba oxhunywe ku-radiator uhlukile, umhlaba awufani, umhlabathi usabanda, futhi ukushisa komhlaba okushisayo kuyafana.

5. Ukunakwa okukhethekile ibanga lomshwalense, indawo eqinile iyadingeka.Ibanga phakathi kwefuse liyahambisana.

6. I-Y capacitor nokuvuza kwamanje, thintana nobudlelwano bamanje.

Ukulandelela kuzochaza ukuthi ungagcina kanjani ibanga kanye nendlela yokwenza izidingo zokuphepha.

- 6. Isakhiwo samandla se-PCB design

1. Okokuqala, linganisa ubukhulu besayizi ye-PCB kanye nenani lamadivayisi, ukuze ibe minyene, ngaphandle kwalokho iqinile, futhi kunzima ukubona ucezu lwe-sparseness.

2. Lungisa umjikelezo, ugxile kumadivayisi ayinhloko, kanye nesimiso sedivayisi eyisihluthulelo yokubeka idivayisi ngesikhathi esisodwa.

3. Idivayisi imile noma ivundlile.Enye yinhle, kanti enye iwukuba lula ukusebenza kwe-plug-in.Izimo ezikhethekile zingacatshangelwa.

4. Uma ukwakheka, udinga ukucabangela i-wiring futhi uyibeke endaweni enengqondo kakhulu futhi wenze lula umugqa wokulandelela.

5. Ngesikhathi sokuhlelwa, indawo yendandatho iyancipha ngangokunokwenzeka, futhi imigwaqo emine emikhulu yendandatho izochazwa ngokuningiliziwe.

Ukufeza amaphuzu angenhla, yiqiniso, kuyadingeka ukuyisebenzisa ngokuguquguqukayo, futhi ukwakheka okunengqondo kuzozalwa maduze.

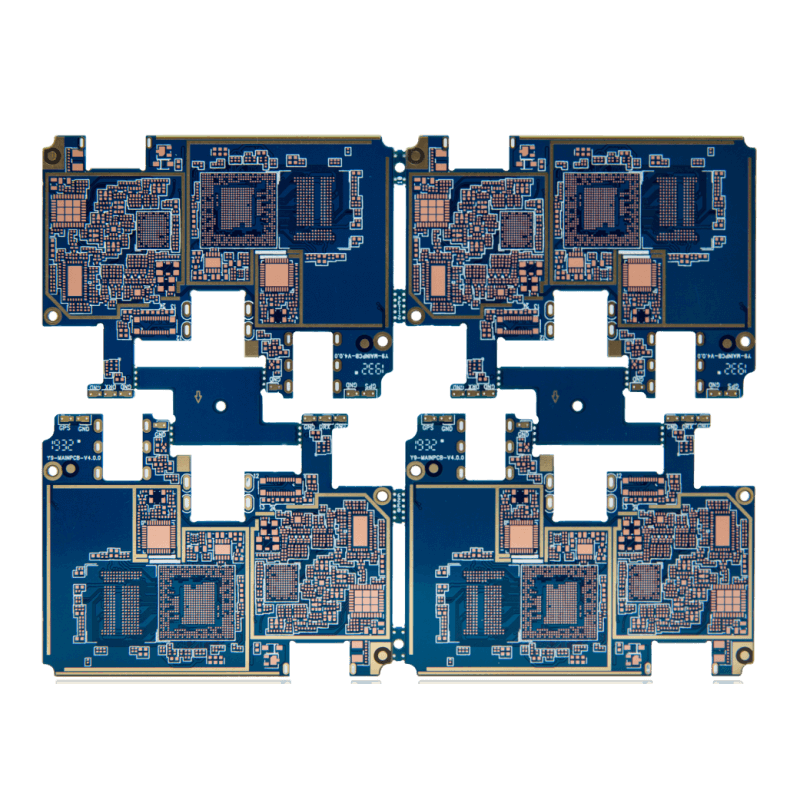

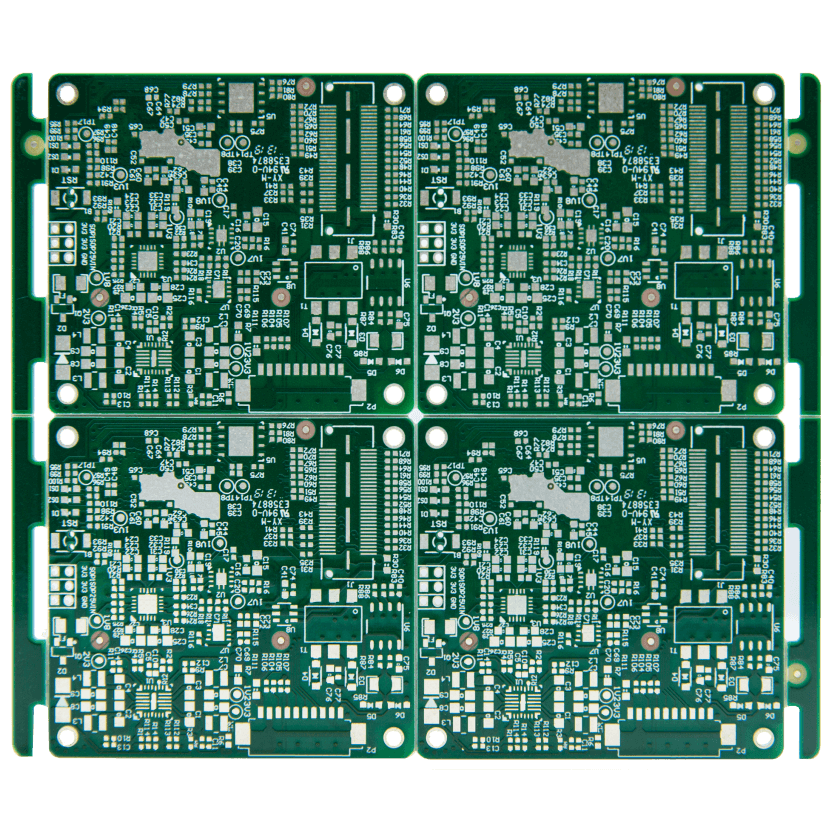

Okulandelayo ibhodi le-PCB, okufanele lifundwe kusakhiwo esijwayelekile:

Ukuminyana kwamandla kwalesi sibalo kusephezulu uma kuqhathaniswa.Phakathi kwazo, ingxenye yokulawula ye-LLC, ingxenye yomthombo osizayo, kanye ne-BUCK circuit drive (high -power multi-road output) kusebhodini elincane.

1. Amatheminali okokufaka nokukhiphayo alungisiwe futhi afile.Ayikwazi ukunyakaza.Ibhodi liwunxande.Ungakhetha kanjani ukugeleza kwamandla okuyinhloko?Lapha, kusukela phansi kuya phezulu, ukusuka kwesobunxele nakwesokudla kuya kusakhiwo, ukuchithwa kokushisa kuncike kugobolondo.

2. Isekhethi ye-EMI isacacile.Lokhu kubaluleke kakhulu.Uma ididekile, ayilungile ku-EMC.

3. Isikhundla sama-capacitor amakhulu kufanele sinakwe iluphu ye-PFC kanye ne-loop yamandla eyinhloko ye-LLC.

4. Umsinga wonqenqema osizayo mkhulu ngokuqhathaniswa.Ukuze kuthathwe i-current and heat dissisation yepayipi yokulungisa, lesi sakhiwo siyamukelwa.Ipayipi lokulungisa lingaphezulu.nje.

Ibhodi ngalinye linezici zalo, futhi vele linezinkinga zalo.Indlela yokuyixazulula ngokunengqondo iyisihluthulelo.Ungakwazi yini ukuqonda incazelo yokukhetha okuphusile kwesakhiwo?

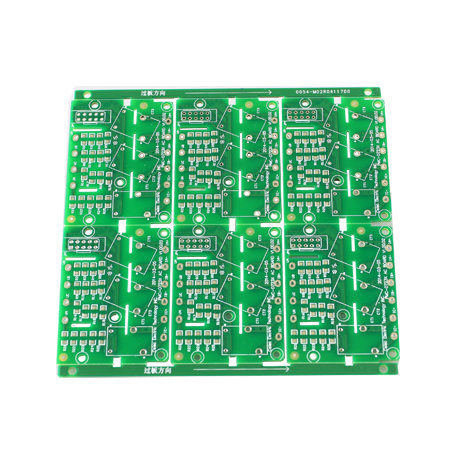

- 7. PCB isibonelo ukwazisa

Ngokusho kwesakhiwo se-PCB sesakhiwo se-PCB okuxoxwe ngaso ngaphambilini, hlola leli bhodi, ukuthi lisendaweni yini, ngicabanga ukuthi liyindawo engcono.Yebo, amaphutha ayohlala ekhona.Ungakwazi futhi ukuyiphakamisa.Akulula, ungafunda kuleli bhodi!Kamuva, uzochaza futhi ufunde leli bhodi.Asibonge kuqala.

- 8. Imigwaqo emine emikhulu eyindandatho yomklamo we-PCB (imfuneko eyisisekelo yokwakheka kwe-PCB indawo encane yamasekethe amaringi amakhulu amane)

Ngaphezu kwalokho, ukumuncwa kwendandatho (ukumuncwa kwe-RCD nokumuncwa kwe-RC kweshubhu le-MOS, ukumuncwa kwe-RC kwamapayipi okulungisa) nakho kubaluleke kakhulu, futhi iyiluphu ekhiqiza imisebe yefrikhwensi ephezulu.Uma unanoma yimiphi imibuzo ngenhla, wamukelekile ukuxoxa ngayo.Uma nje kubuzwa ngemibuzo, ukuxoxa ngokufunda ndawonye kungenza intuthuko enkulu!