I-SMT isebenzisa ukuhlaziya okuvamile kwe-solder paste air reflow welding welding kanye nesisombululo (2023 Essence Edition), kuyakufanelekela!

1 Isingeniso

Emhlanganweni webhodi lesifunda, i-solder paste inyatheliswa ebhodini lesifunda le-solder pad kuqala, bese kufakwa izingxenye ezihlukahlukene ze-electronic. Ekugcineni, ngemva kwesithando somlilo sokugeleza kabusha, ubuhlalu bethayela ekunamathiseleni kwe-solder buyancibilika futhi zonke izinhlobo zezingxenye ze-elekthronikhi kanye ne-solder pad yebhodi lesifunda zishiselwa ndawonye ukuze kubonakale ukuhlanganiswa kwama-submodules kagesi. i-surfacemounttechnology (sMT) isetshenziswa ngokwandayo emikhiqizweni yokupakisha enokuminyana okuphezulu, njengephakheji yeleveli yesistimu (i-siP), amadivayisi we-ballgridarray (BGA), kanye ne-Chip engenalutho, iphakheji yesikwele esiyisikwele se-pin-less (quad aatNo-lead, ebizwa ngokuthi idivayisi ye-QFN).

Ngenxa izici solder unama Welding inqubo kanye materials, ngemva reflow Welding la madivayisi solder surface surface, kuyoba nezimbobo endaweni Solder Welding, okuzothinta izakhiwo kagesi, izakhiwo ezishisayo kanye izakhiwo mechanical of the Performance umkhiqizo, futhi ngisho kuholele ekuhlulekeni komkhiqizo, Ngakho-ke, ukuze ngcono solder unama reflow Welding imbobo isibe inqubo kanye nenkinga yezobuchwepheshe ukuthi abanye bacwaninga i-balder ibangela ukuxazululwa kwe-balder. imbobo yokushisela, kanye nezixazululo ezithuthukisiwe, inqubo yokushisela ye-solder evamile yokunamathisela kabusha yenqubo yokushisela ye-QFN enkulu kuno-10mm2 noma indawo yokushisela enkulu kuno-6 mm2's bare chip solution iyantuleka.

Sebenzisa i-Preformsolder welding kanye ne-vacuum reflux furnace welding ukuze uthuthukise imbobo yokushisela. I-solder eyenziwe ngaphambilini idinga imishini ekhethekile ukukhomba ukugeleza. Isibonelo, i-chip iyasuswa futhi itshekisiwe ngokujulile ngemuva kokuthi i-chip ibekwe ngqo kusoda esenziwe ngaphambili. Uma i-flux Mount chip igeleza kabusha bese ikhomba, inqubo ikhuphuka ngokugeleza kabusha okubili, futhi izindleko ze-solder eyenziwe ngaphambili kanye nezinto ezixutshwayo ziphakeme kakhulu kunonamathisela okuthengiswayo.

Imishini ye-vacuum reflux ibiza kakhulu, umthamo we-vacuum wegumbi elizimele le-vacuum liphansi kakhulu, ukusebenza kwezindleko akuphakeme, futhi inkinga yokufafazwa kwe-tin ibucayi, okuyisici esibalulekile ekusetshenzisweni kwemikhiqizo e-high-density kanye ne-pitch encane. Kuleli phepha, ngokusekelwe kunqubo evamile ye-solder paste reflow welding, inqubo entsha ye-reflow welding entsha iyathuthukiswa futhi yethulwa ukuze kuthuthukiswe i-welding cavity nokuxazulula izinkinga zokubopha kanye nokuqhekeka kwe-plastic seal okubangelwa i-welding cavity.

2 I-Solder unama ukuphrinta ukugeleza kabusha kwe-welding cavity kanye nendlela yokukhiqiza

2.1 Umgodi wokushisela

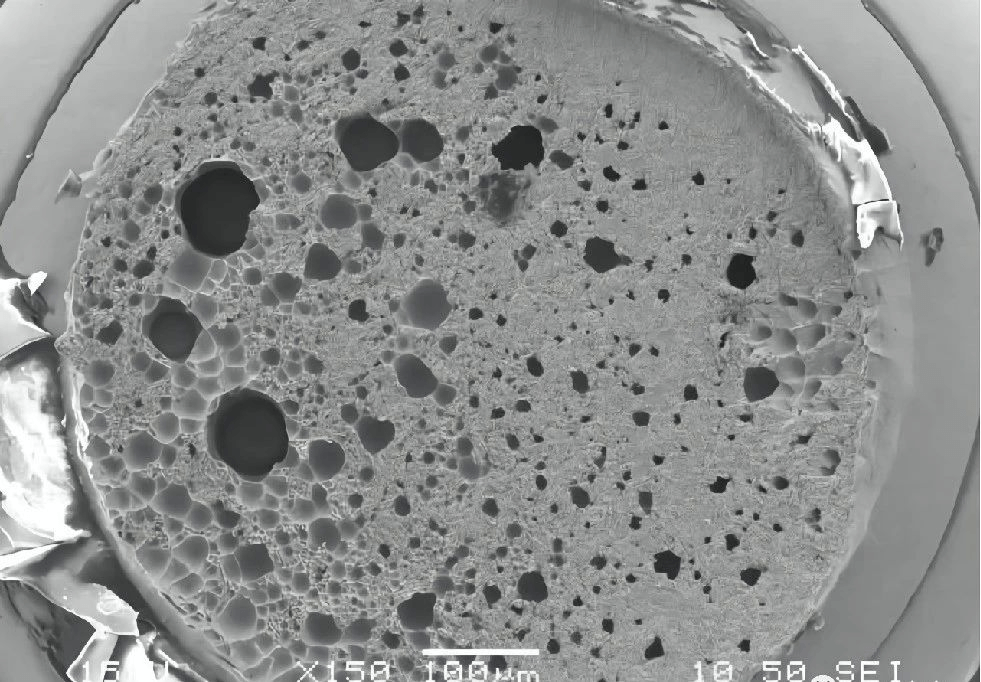

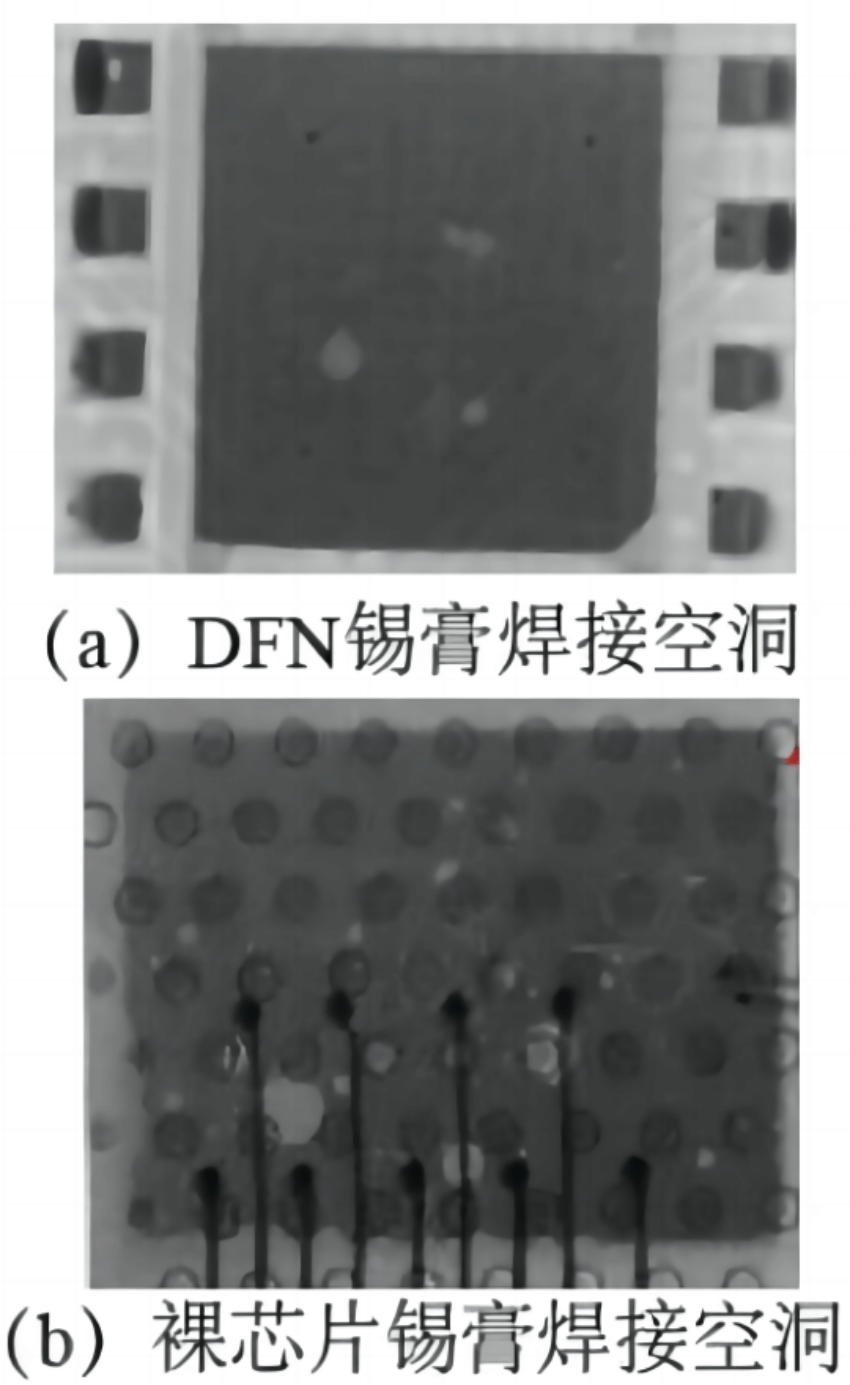

Ngemuva kwe-reflow welding, umkhiqizo wahlolwa ngaphansi kwe-x-ray. Izimbobo endaweni yokushisela ezinombala okhanyayo kutholwe ukuthi kungenxa yokunganele kwe-solder kungqimba lokushisela, njengoba kuboniswe kuMfanekiso 1.

Ukutholwa kwe-X-ray kwembobo yebhamuza

2.2 Indlela yokwakhiwa kwe-welding cavity

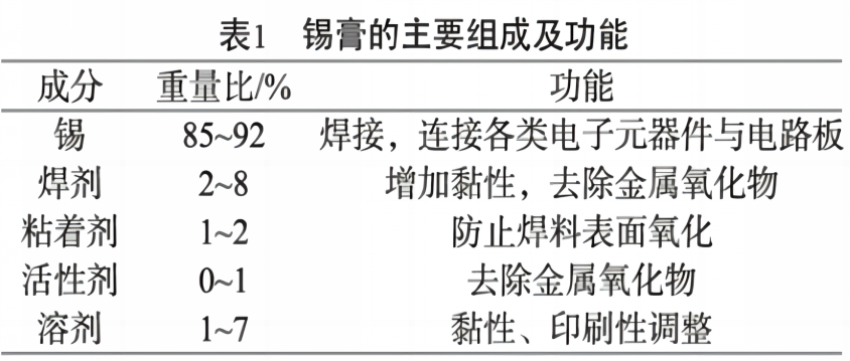

Uma sithatha i-sAC305 solder paste njengesibonelo, ukwakheka okuyinhloko nomsebenzi kukhonjiswe kuThebula 1. Ubuhlalu obuguquguqukayo nobuthayela buhlanganiswe ndawonye ngendlela yokunamathisela. Isilinganiso sesisindo se-tin solder kuya ku-flux singaba ngu-9: 1, kanti isilinganiso sevolumu singaba ngu-1: 1.

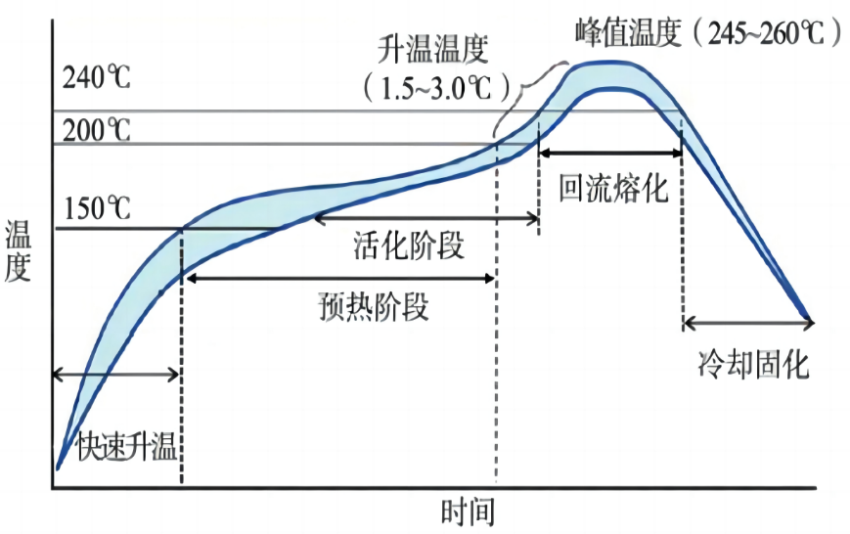

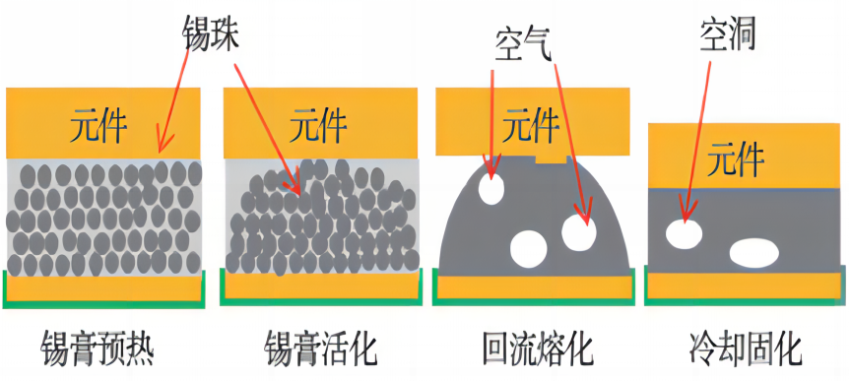

Ngemuva kokuthi i-solder paste iphrintiwe futhi ifakwe ngezinto ezihlukahlukene ze-elekthronikhi, i-solder paste izobhekana nezigaba ezine zokushisa, ukuqalisa, i-reflux nokupholisa lapho idlula esithandweni somlilo se-reflux. Isimo se-solder paste sihlukile futhi namazinga okushisa ahlukene ngezigaba ezahlukene, njengoba kuboniswe kuMfanekiso 2.

Ireferensi yephrofayela yendawo ngayinye ye-reflow soldering

Esigabeni sokuqala sokushisa nesokwenza kusebenze, izingxenye eziguquguqukayo ku-flux ku-solder paste zizoshintsha zibe yigesi uma kushisa. Ngesikhathi esifanayo, amagesi azokhiqizwa lapho i-oxide ebusweni bengqimba yokushisela isuswa. Amanye alawa magesi azoshintshashintsha futhi ashiye i-solder paste, futhi ubuhlalu be-solder buzoqiniswa ngokuqinile ngenxa yokuguquguquka kwe-flux. Esigabeni se-reflux, i-flux esele ku-solder paste izoshabalala ngokushesha, ubuhlalu bethayela buzoncibilika, inani elincane legesi eguquguqukayo eguquguqukayo futhi umoya omningi phakathi kobuhlalu bethini ngeke uhlakazeke ngokuhamba kwesikhathi, futhi okusele ethini elincibilikisiwe nangaphansi kokungezwani kwethayela elincibilikisiwe kubanjwa ama-hamburger nesakhiwo se-electronic sandwich okusongwe ngethini eliwuketshezi kunzima ukuphunyuka kuphela ngokukhuphuka phezulu Isikhathi sokuncibilika esiphezulu sifushane kakhulu. Lapho ithini elincibilikisiwe liphola futhi liba ithini eliqinile, kuvela izimbotshana ongqimbeni olushiselayo bese kwakheka izimbobo zokudambisa, njengoba kuboniswe kuMfanekiso 3.

Umdwebo we-schematic we-void owenziwe i-solder paste reflow welding

Imbangela ye-welding cavity ukuthi umoya noma igesi eguquguqukayo esongwe nge-solder paste ngemva kokuncibilika ayikhishwa ngokuphelele. Izici ezithonya zihlanganisa izinto zokunamathisela i-solder, ukuma kokuphrinta kwe-solder, inani lokuphrinta le-solder, izinga lokushisa le-reflux, isikhathi se-reflux, usayizi we-welding, isakhiwo nokunye.

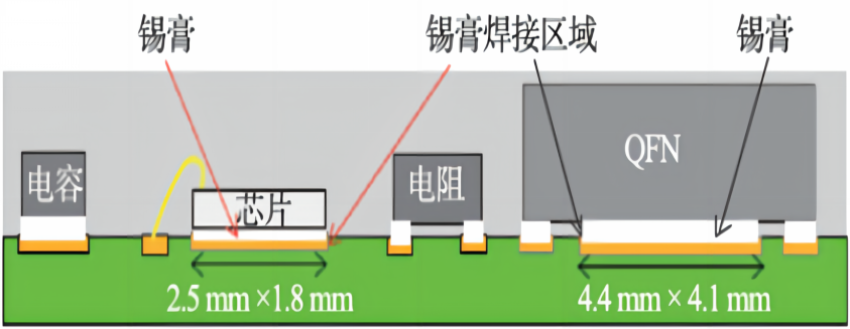

3. Ukuqinisekiswa kwezici ezinomthelela we-solder unama ukuphrinta ukuphinda kugeleze izimbobo zokushisela

I-QFN kanye nokuhlolwa kwe-chip engenalutho kwasetshenziselwa ukuqinisekisa izimbangela eziyinhloko ze-reflow welding voids, kanye nokuthola izindlela zokuthuthukisa i-reflow welding voids ephrintiwe nge-solder paste. Iphrofayili yomkhiqizo we-QFN kanye ne-bare chip solder inamathisela ukugeleza kabusha komkhiqizo we-welding iboniswa kuMfanekiso 4, usayizi wendawo yokushisela we-QFN ngu-4.4mmx4.1mm, indawo yokushisela iyisendlalelo esithayiniwe (100% ithini elihlanzekile); Usayizi wokushisela we-chip engenalutho ngu-3.0mmx2.3mm, ungqimba lwe-welding luyi-sputtered nickel-vanadium bimetallic layer, kanti ungqimba olungaphezulu luyi-vanadium. Iphedi yokushisela ye-substrate yayiyi-electroless nickel-palladium gold-dipping, futhi ukujiya kwakungu-0.4μm/0.06μm/0.04μm. I-SAC305 solder paste isetshenziswa, okokusebenza kokuphrinta kwe-solder paste yi-DEK Horizon APix, okokusebenza kwe-reflux furnace yi-BTUPyramax150N, kanti okokusebenza kwe-x-ray ithi DAGExD7500VR.

I-QFN nemidwebo ye-welding ye-chip engenalutho

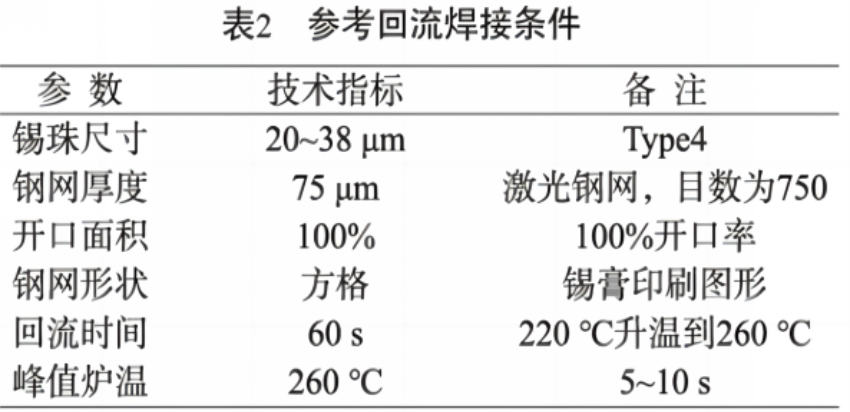

Ukuze kube lula ukuqhathanisa imiphumela yokuhlolwa, ukushiselwa kabusha kwe-reflow kwenziwa ngaphansi kwezimo ezikuThebula lesi-2.

Ithebula lesimo sokushisela kabusha

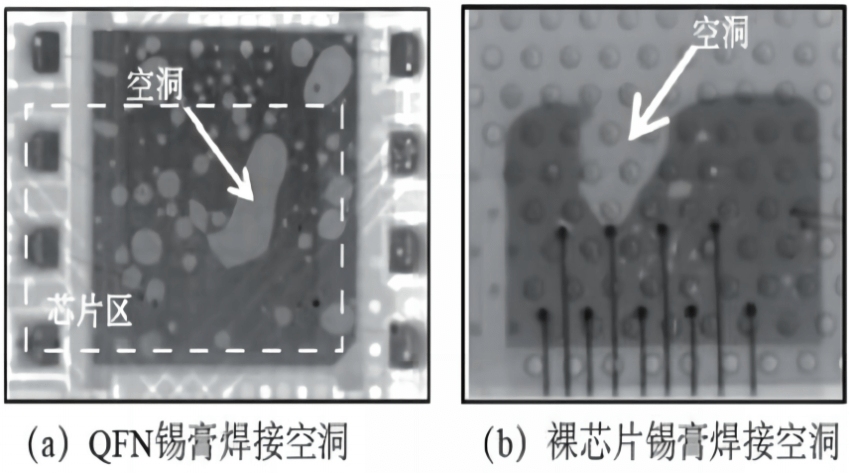

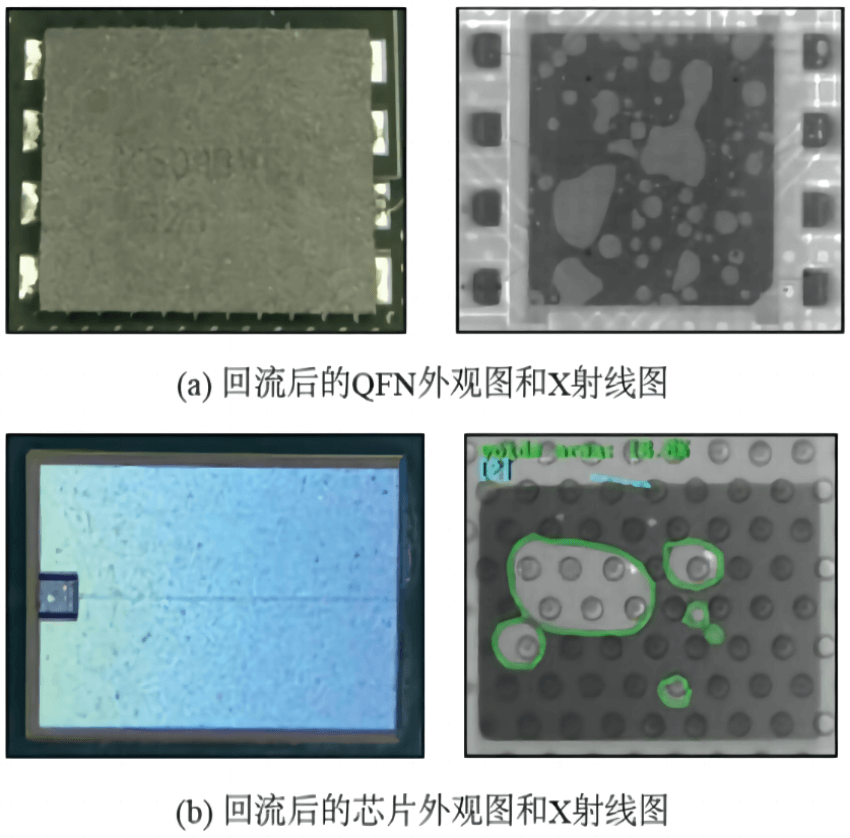

Ngemva kokuphothulwa kwe-surface mounting and reflow welding, ungqimba lwe-welding lwatholwa nge-X-ray, futhi kwatholakala ukuthi kunezimbobo ezinkulu kungqimba lokushisela ngaphansi kwe-QFN kanye ne-chip engenalutho, njengoba kuboniswe kuMfanekiso 5.

I-QFN ne-Chip Hologram (X-ray)

Njengoba usayizi we-tin bead, ukushuba kwensimbi yensimbi, izinga lokuvula indawo, ukuma kwensimbi yensimbi, isikhathi se-reflux kanye nezinga lokushisa lomlilo eliphakeme kuzothinta i-reflow welding voids, kunezici eziningi ezinomthelela, ezizoqinisekiswa ngokuqondile ukuhlolwa kwe-DOE, futhi inani lamaqembu okuhlola lizoba likhulu kakhulu. Kuyadingeka ukuthi uhlole ngokushesha futhi unqume izici ezinomthelela omkhulu ngokuhlolwa kokuqhathanisa, bese uthuthukisa ngokwengeziwe izici ezithonyayo nge-DOE.

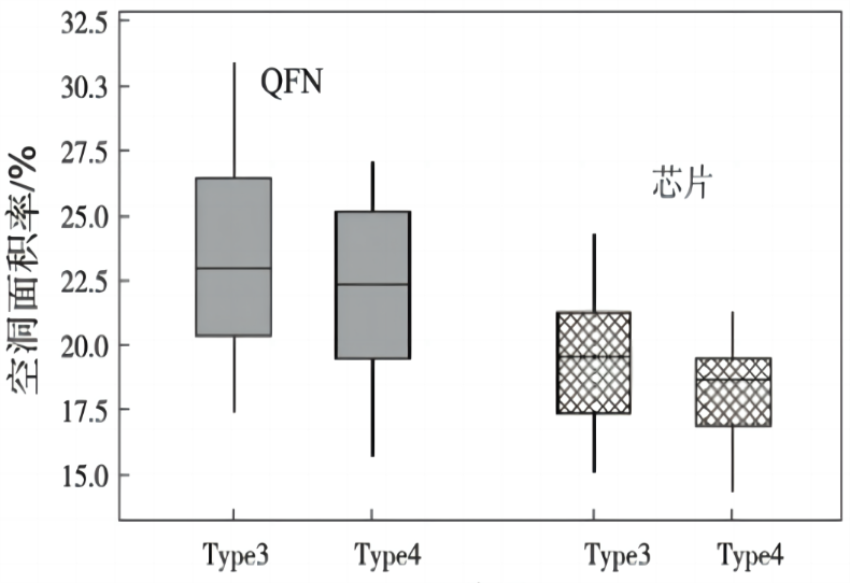

3.1 Ubukhulu bezimbobo ze-solder kanye nobuhlalu bothayela obunamathiselayo

Ngohlobo3 (usayizi wobuhlalu 25-45 μm) Ukuhlolwa kokunamathisela kwe-solder ye-SAC305, ezinye izimo zihlala zingashintshile. Ngemuva kokugeleza kabusha, izimbobo kungqimba lwe-solder ziyalinganiswa futhi ziqhathaniswe ne-type4 solder paste. Kutholakala ukuthi izimbobo kungqimba ye-solder azihlukile kakhulu phakathi kwezinhlobo ezimbili zokunamathisela kwe-solder, okubonisa ukuthi ukunamathisela kwe-solder enobukhulu obuhlukene be-bead ayinalo ithonya elisobala emigodini ye-solder layer, engeyona into enomthelela, njengoba kuboniswe ku-FIG. 6 Njengoba kukhonjisiwe.

Ukuqhathaniswa kwezimbobo ze-metallic tin powder ezinosayizi wezinhlayiyana ezihlukene

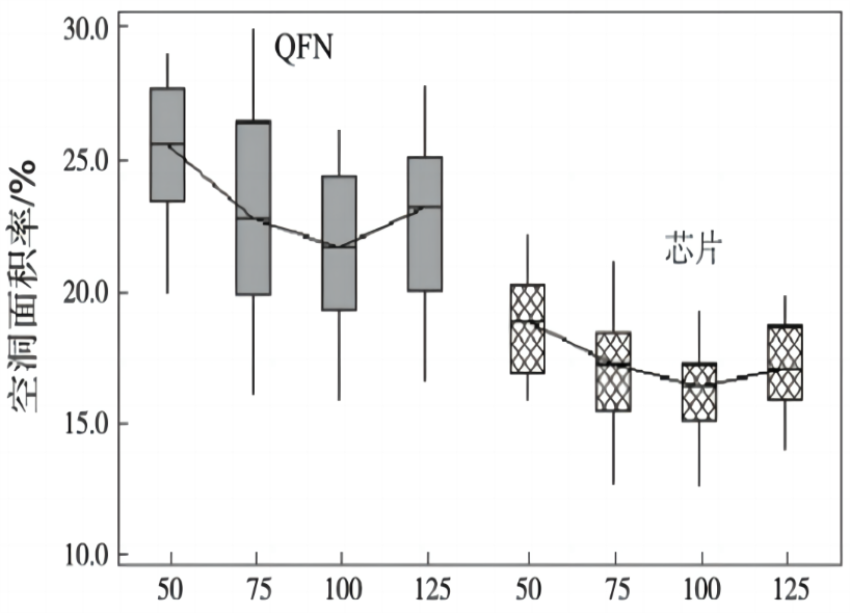

3.2 Ubukhulu bomgodi wokushisela kanye nensimbi ephrintiwe

Ngemuva kokugeleza kabusha, indawo ye-cavity yesendlalelo esishiselwe ikalwa nge-mesh yensimbi ephrintiwe enobukhulu obungu-50 μm, 100 μm no-125 μm, nezinye izimo zahlala zingashintshiwe. Kutholwe ukuthi umthelela wogqinsi oluhlukene lwe-mesh yensimbi (i-solder paste) ku-QFN uqhathaniswe nalowo wemeshi yensimbi ephrintiwe enogqinsi luka-75 μm Njengoba ukushuba kwemeshi yensimbi kwanda, indawo yomgodi iyancipha kancane kancane. Ngemva kokufinyelela ugqinsi oluthile (100μm), indawo yomgodi izohlehla futhi iqale ukwanda ngokwanda kogqinsi lwemeshi yensimbi, njengoba kuboniswe kuMfanekiso 7.

Lokhu kukhombisa ukuthi lapho inani lokunamathisela kwe-solder likhuphuka, ithini eliwuketshezi eline-reflux limbozwa yi-chip, futhi ukuphuma komoya okusele kuncane kuphela ezinhlangothini ezine. Uma inani lokunamathisela kwe-solder lishintshwa, indawo yokuphuma komoya eyinsalela nayo iyakhuphuka, futhi ukuqhuma komoya okusheshayo esongwe ngothayela oluwuketshezi noma igesi eguquguqukayo ephunyuka kuthini oluwuketshezi kuzobangela uthayela oluwuketshezi ukuba luchaphaze eduze kwe-QFN kanye ne-chip.

Ukuhlola kutholwe ukuthi ngokukhula kokuqina kwensimbi enezikhala, ukuqhuma kwebhamuza okubangelwa ukuphunyuka komoya noma igesi eguquguqukayo nakho kuzokhuphuka, futhi amathuba okuchaphazeka kwethini azungeze i-QFN ne-chip nawo azokhuphuka ngokufanayo.

Ukuqhathaniswa kwezimbobo zensimbi yensimbi enogqinsi oluhlukene

3.3 Isilinganiso sendawo yomgodi wokushisela nokuvuleka kwensimbi yensimbi

I-mesh yensimbi ephrintiwe enezinga lokuvula le-100%, i-90% ne-80% ihlolwe, futhi ezinye izimo zahlala zingashintshiwe. Ngemuva kokugeleza kabusha, indawo ye-cavity yesendlalelo esishiselwe yalinganiswa futhi yaqhathaniswa ne-mesh yensimbi ephrintiwe enezinga lokuvula elingu-100%. Kwatholakala ukuthi kwakungekho umehluko obalulekile emgodini wengqimba eshiselwe ngaphansi kwemibandela yezinga lokuvula lika-100% no-90% 80%, njengoba kuboniswe kuMfanekiso 8.

Ukuqhathaniswa kwe-cavity yendawo ehlukene yokuvula ye-mesh yensimbi ehlukene

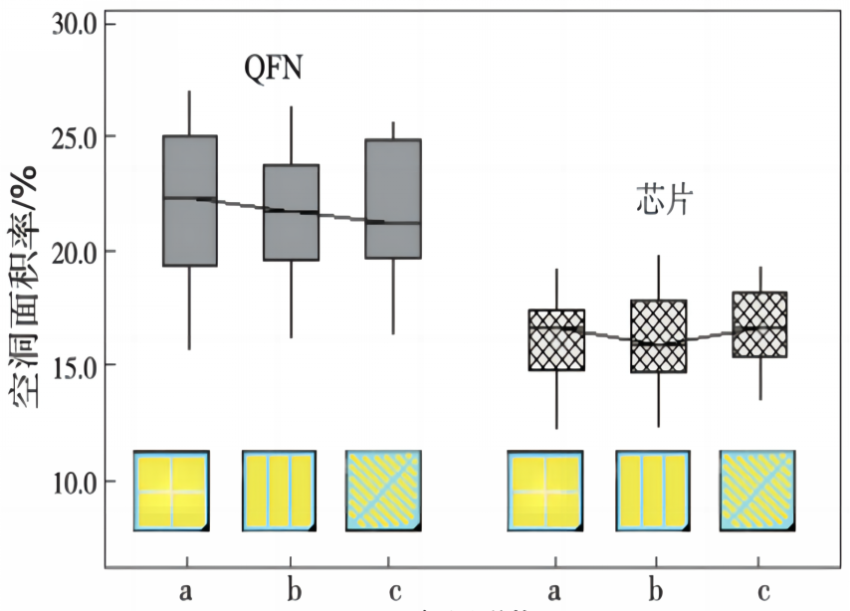

3.4 Imbobo eshiselwe kanye nomumo wemeshi wensimbi ophrintiwe

Ngokuhlolwa komumo wokuphrinta we-solder paste ye-strip b kanye negridi ethambekele c, ezinye izimo zihlala zingashintshile. Ngemuva kokugeleza kabusha, indawo ye-cavity ye-welding layer iyalinganiswa futhi iqhathaniswe nesimo sokuphrinta segridi a. Kutholakala ukuthi awukho umehluko obalulekile emgodini we-welding layer ngaphansi kwezimo zegridi, i-strip kanye negridi ethambekele, njengoba kuboniswe kuMfanekiso 9.

Ukuqhathaniswa kwezimbobo ngezindlela ezahlukene zokuvula zensimbi yensimbi

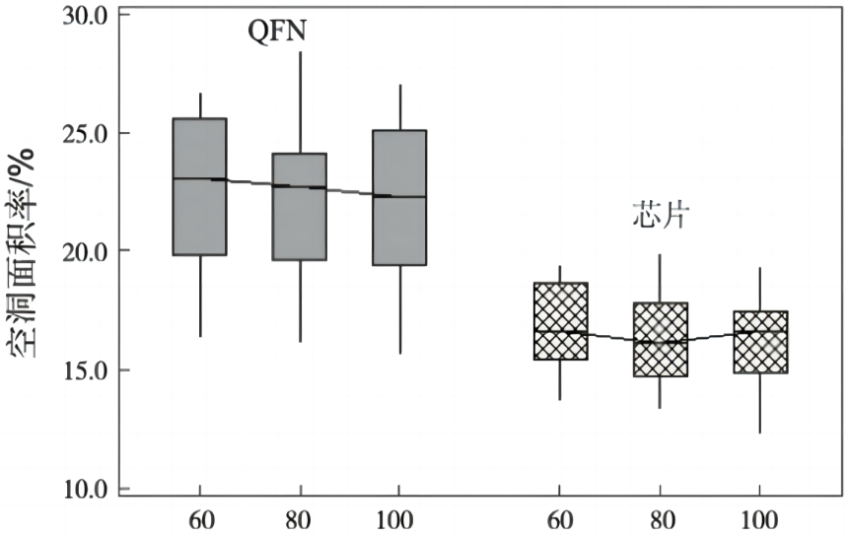

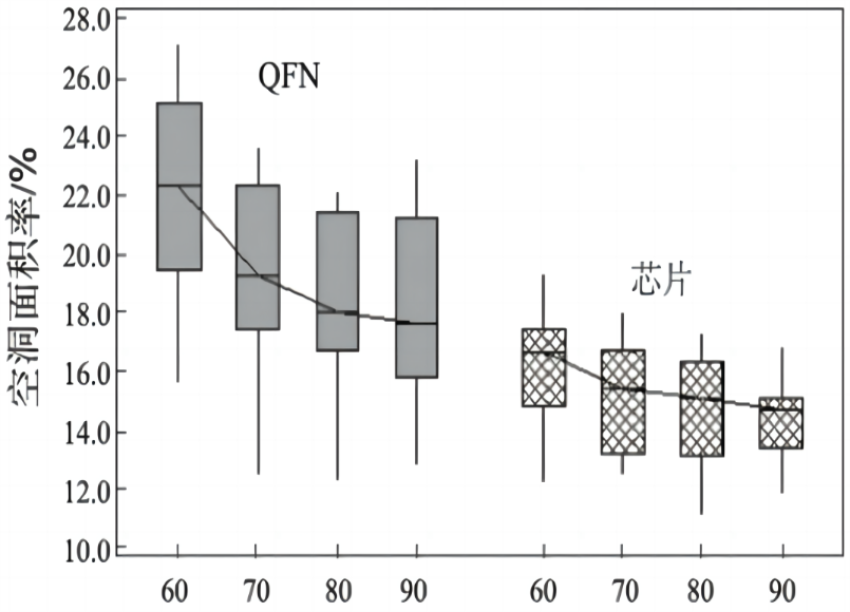

3.5 Imbobo yokushisela kanye nesikhathi se-reflux

Ngemuva kokuhlolwa kwesikhathi eside se-reflux (70 s, 80 s, 90 s), ezinye izimo zihlala zingashintshiwe, imbobo esesigabeni sokushisela ikalwa ngemuva kwe-reflux, futhi uma kuqhathaniswa nesikhathi se-reflux se-60 s, kwatholakala ukuthi ngokukhula kwesikhathi se-reflux, indawo yembobo yokushisela iyancipha, kodwa ukuncipha kwesilinganiso se-amplitude ekhonjisiwe kancane kancane kubonisa ukuthi i-amplitude iyancipha kancane kancane. esimweni sesikhathi esinganele se-reflux, ukwandisa isikhathi se-reflux kusiza ekuchichimeni okugcwele komoya okugoqwe ngethini eliwuketshezi elincibilikisiwe, kodwa ngemva kokuba isikhathi se-reflux sikhuphuka siye esikhathini esithile, umoya osongwe ngethini eliwuketshezi kunzima ukuchichima futhi. Isikhathi se-Reflux singenye yezinto ezithinta i-welding cavity.

Ukuqhathaniswa okungenalutho kobude besikhathi be-reflux obuhlukene

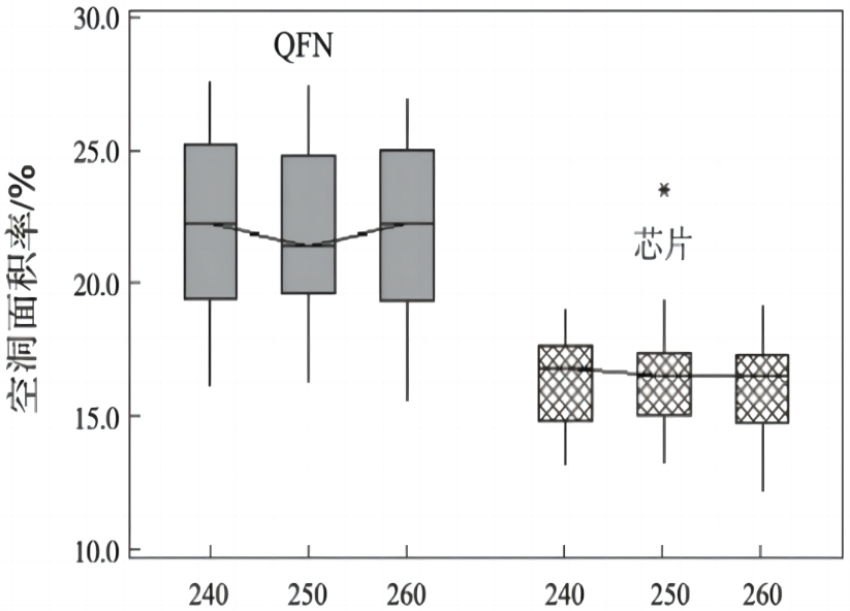

3.6 Imbobo yokushisela kanye nezinga lokushisa eliphakeme kakhulu lesithando somlilo

Ngokuhlolwa kwezinga lokushisa kweziko elingu-240 ℃ no-250 ℃ eliphakeme nezinye izimo ezingashintshiwe, indawo yomgodi wengqimba eshiselwe ikalwa ngemva kokugeleza kabusha, futhi uma kuqhathaniswa nezinga lokushisa eliphakeme elingu-260 ℃, kwatholakala ukuthi ngaphansi kwezimo ezihlukene zokushisa kwesithando somlilo, imbobo yongqimba olushiselwe ku-QFN ayizange ishintshe kakhulu. izinga lokushisa eliphakeme lesithando somlilo alinawo umthelela osobala ku-QFN kanye nembobo esesigabeni sokushisela se-chip, engeyona into enomthelela.

Ukuqhathaniswa okuyize kwamazinga okushisa aphakeme ahlukene

Ukuhlola okungenhla kukhombisa ukuthi izici ezibalulekile ezithinta i-weld layer ye-QFN kanye ne-chip isikhathi se-reflux kanye nogqinsi lwe-mesh yensimbi.

4 Ukuthuthukiswa kokuphrinta kokuphrinta kwe-solder ukugeleza kabusha kwe-welding cavity

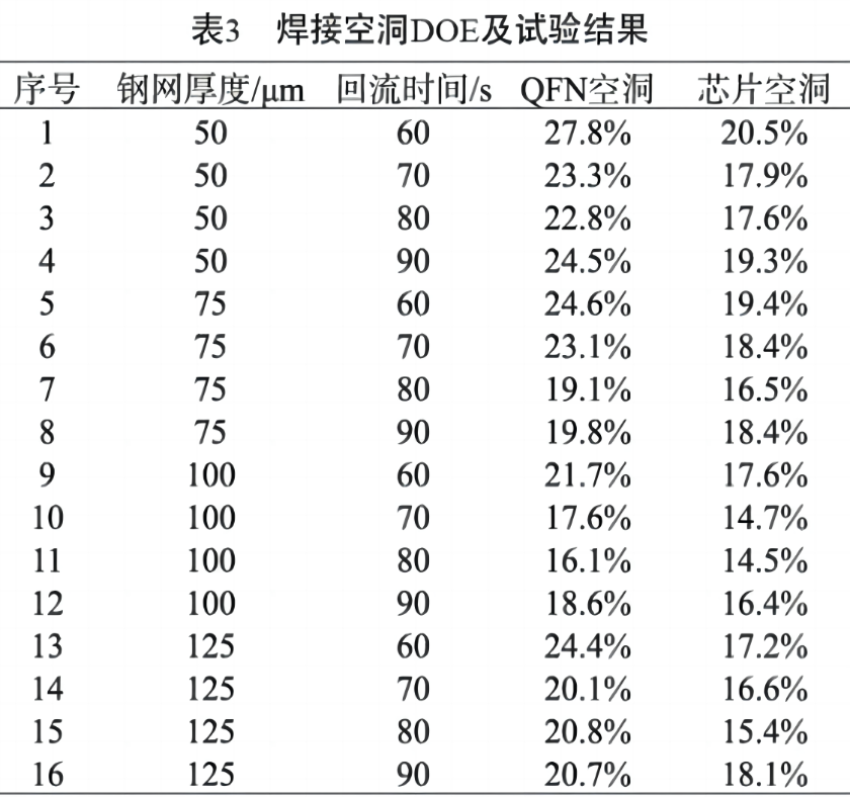

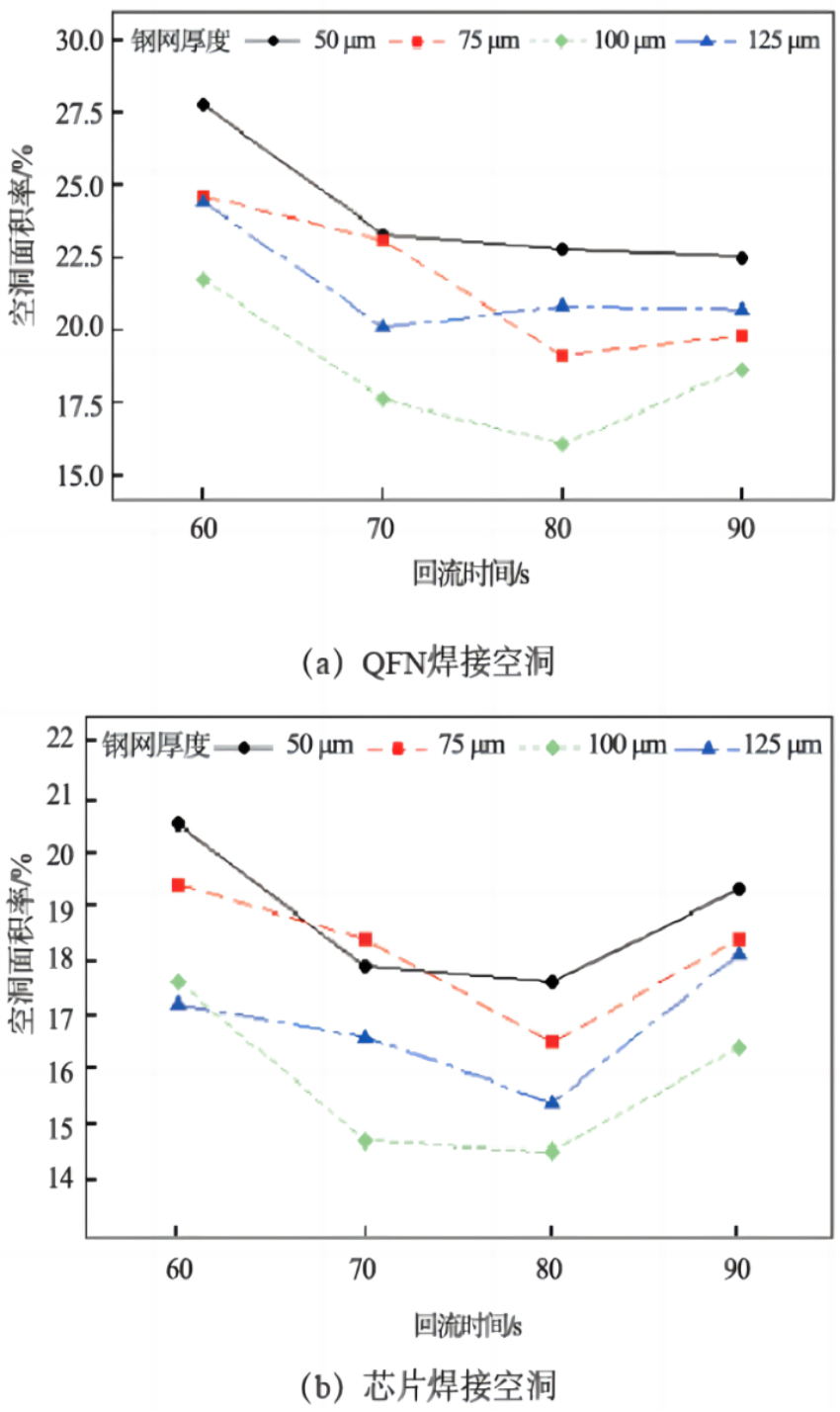

Ukuhlolwa kwe-4.1DOE ukuthuthukisa umgodi wokushisela

Imbobo kungqimba lokushisela lwe-QFN ne-chip yathuthukiswa ngokuthola inani elifanele lezinto ezithonyayo eziyinhloko (isikhathi se-reflux kanye nogqinsi lwe-mesh yensimbi). I-solder paste yayiyi-SAC305 type4, umumo we-mesh yensimbi wawuwuhlobo lwegridi (idigri yokuvula engu-100%), izinga lokushisa eliphakeme lesithando somlilo lalingu-260 ℃, nezinye izimo zokuhlola zazifana nalezo zemishini yokuhlola. Ukuhlolwa kwe-DOE kanye nemiphumela kuboniswe kuThebula 3. Amathonya okuqina kwensimbi yensimbi kanye nesikhathi se-reflux ku-QFN nezimbobo ze-chip welding kuboniswa kuMdwebo 12. Ngokuhlaziywa kokuxhumana kwezici ezithonya eziyinhloko, Kutholakala ukuthi ukusebenzisa i-100 μm yensimbi yensimbi ukujiya kanye nesikhathi se-reflux esingu-80 s kunganciphisa kakhulu i-welding chip ye-QN cavity. Izinga lokushisela le-QFN lincishisiwe lisuka ku-27.8% laya ku-16.1%, kanti izinga lokushisela le-chip liyehla lisuka ku-20.5% laya ku-14.5%.

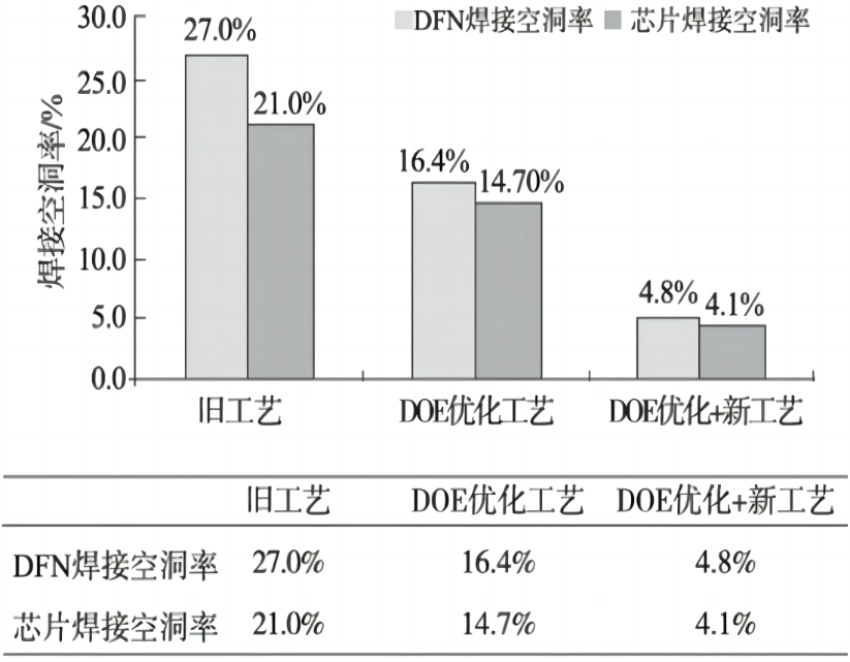

Esivivinyweni, imikhiqizo eyi-1000 yakhiqizwa ngaphansi kwezimo ezifanele (ugqinsi lwensimbi eyi-100 μm, isikhathi se-reflux esingu-80s), futhi izinga lokushisela le-100 QFN ne-chip likalwe ngokungahleliwe. Isilinganiso sesilinganiso sokushisela se-QFN sasingu-16.4%, futhi isilinganiso sesilinganiso sokushisela se-chip sasingu-14.7% Izinga le-weld cavity ye-chip ne-chip ngokusobala liyehlisiwe.

4.2 Inqubo entsha ithuthukisa imbobo yokushisela

Isimo sokukhiqiza sangempela kanye nokuhlolwa kubonisa ukuthi lapho indawo ye-welding cavity ngaphansi kwe-chip ingaphansi kuka-10%, inkinga yokuqhekeka kwe-chip cavity ngeke yenzeke ngesikhathi sokubopha nokubumba okuholayo. Imingcele yenqubo eyenziwe ngcono yi-DOE ayikwazi ukuhlangabezana nezidingo zokuhlaziya nokuxazulula izimbobo ku-solder paste reflow welding evamile, futhi izinga lendawo yokushisela ye-chip lidinga ukuncishiswa nakakhulu.

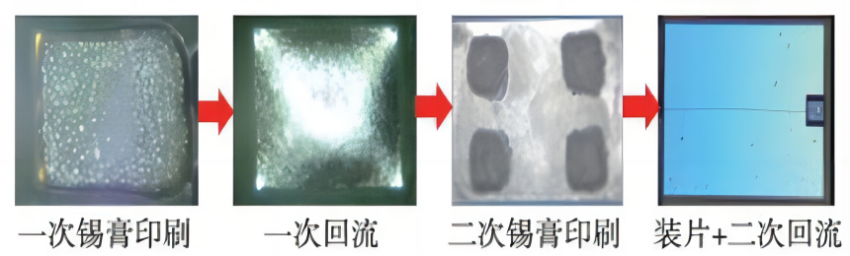

Njengoba i-chip embozwe ku-solder ivimbela igesi e-solder ekuphunyukeni, izinga lembobo elingaphansi kwe-chip liyancipha ngokususa noma ukunciphisa igesi eboshwe nge-solder. Inqubo entsha ye-reflow welding ngokuphrinta kokunamathisela kwe-solder iyamukelwa: ukuphrinta kokunamathisela kwe-solder eyodwa, ukugeleza okukodwa okungafaki i-QFN kanye ne-chip engenalutho ekhipha igesi ku-solder; Inqubo ethile yokuphrinta i-solder paste yesibili, i-patch kanye ne-reflux yesibili iboniswa kuMfanekiso 13.

Lapho ukunamathisela kwe-solder okuwugqinsi okungu-75μm kunyatheliswa okokuqala, igesi eningi ekwi-solder ngaphandle kwekhava ye-chip iyaphuma ebusweni, futhi ukujiya ngemva kwe-reflux cishe ku-50μm. Ngemva kokuphothulwa kwe-reflux eyinhloko, izikwele ezincane zinyatheliswa ebusweni be-solder epholile eqinile (ukuze kuncishiswe inani le-solder paste, ukunciphisa inani le-gas spillover, ukunciphisa noma ukuqeda i-solder spatter), kanye ne-solder paste enogqinsi lwama-50 μm (imiphumela yokuhlola engenhla ibonisa ukuthi u-100 μm ungcono kakhulu we-50 μm, ugqinsi lwesibili lwe-50 μm. μm=50 μm), bese ufaka i-chip, bese ubuya ngemizuzwana engama-80. Cishe ayikho imbobo ku-solder ngemva kokunyathelisa nokugeleza kabusha kokuqala, futhi i-solder paste ekuphrintiwe kwesibili incane, futhi imbobo yokushisela incane, njengoba kuboniswe kuMfanekiso 14.

Ngemuva kokuphrinta okubili kokunamathisela kwe-solder, umdwebo ongenalutho

4.3 Ukuqinisekiswa komphumela we-welding cavity

Ukukhiqizwa kwemikhiqizo ye-2000 (ubukhulu bensimbi yokuqala yokunyathelisa yensimbi ingu-75 μm, ubukhulu bensimbi yesibili yokunyathelisa i-50 μm), ezinye izimo zingashintshiwe, ukulinganisa okungahleliwe kwe-500 QFN kanye nesilinganiso se-chip welding, kutholakale ukuthi inqubo entsha emva kwe-reflux yokuqala ayikho i-cavity, ngemva kwe-reflux yesibili yokushisela izinga le-QFN izinga eliphezulu le-4. i-chip ingu-4.1%. Uma kuqhathaniswa nenqubo yokuqala yokuphrinta yokuphrinta okukodwa kanye nenqubo eyenziwe kahle ye-DOE, indawo yokushisela iyancipha kakhulu, njengoba kuboniswe kuMfanekiso 15. Akukho mifantu ye-chip etholwe ngemva kokuhlolwa kokusebenza kwayo yonke imikhiqizo.

5 Isifinyezo

Ukulungiswa kwenani lokuphrinta lokunamathisela kwe-solder kanye nesikhathi se-reflux kunganciphisa indawo ye-welding cavity, kodwa izinga le-welding cavity liselikhulu. Ukusebenzisa izindlela ezimbili zokuphrinta zokuphrinta ukuphrinta kwe-solder zingase ngempumelelo futhi zikhulise izinga lokushisela. Indawo yokushisela ye-QFN circuit bare chip ingaba ngu-4.4mm x4.1mm kanye no-3.0mm x2.3mm ngokulandelana ekukhiqizeni okukhulu Izinga le-cavity ye-reflow welding lilawulwa ngaphansi kuka-5%, okuthuthukisa ikhwalithi nokuthembeka kwe-reflow welding. Ucwaningo kuleli phepha lunikeza ireferensi ebalulekile yokuthuthukisa inkinga ye-welding cavity yendawo enkulu yokushisela.