I-Circuit Board Manufacturing & PCB Assembly & Electronic Assembly service & nenkampani ekhiqiza izinto zikagesi - XinDaChang Co., Limited

Njengomhlinzeki wezinsizakalo ze-PCB Assembly ohamba phambili e-China, i-At XinDaChang inikezela ngemikhiqizo yebhodi ye-PCB esezingeni eliphezulu, engabizi kakhulu futhi evezwayo futhi ihlinzeka ngokwenziwa kwe-PCB, ukukhiqizwa kokuhlanganiswa kwama-elekthronikhi, ukutholakala kwezingxenye, ukuhlanganisa i-Box build kanye nezinsizakalo zokuhlola i-PCBA kumakhasimende ethu.

Ukuze uthole umhlangano ogcwele webhodi lesifunda lokhiye wokuvula, sinakekela yonke inqubo, okuhlanganisa ukwenziwa kwamabhodi Esifunda Aphrintiwe, ukutholakala kwezingxenye, ukulandelela ama-oda, ukuqapha okuqhubekayo kwekhwalithi kanye nomhlangano wokugcina webhodi le-PCB. Nakuba ngokhiye wokuvula ngokwengxenye, ikhasimende linganikeza ama-PCB nezinye izingxenye, futhi izingxenye ezisele zizophathwa yithi.

Iyini inhlangano ye-PCB

Ibhodi lesifunda ngaphambi kokuhlanganiswa kwezingxenye zikagesi libizwa ngokuthi I-Printed Circuit Board. Ngemuva kokuhlanganiswa kwazo zonke izakhi ebhodini, kwaziwa ngokuthi Ibhodi Lesifunda Eliphrintiwe Lihlanganisiwe, sabizaUkuhlanganiswa kwe-PCB. Inqubo ephelele yokuhlanganisa ingxenye ibizwa ngokuthi umhlangano we-Printed Circuit Assembly noma i-Printed Circuit Board noma umhlangano webhodi le-PCB. Kule nqubo, kusetshenziswa amathuluzi ahlukene wokuhlanganisa othomathikhi kanye namabhukwana. Singama-assembler anikeza umhlangano we-PCB.

Imibuzo Evame Ukubuzwa ye-XinDaChang – PCB Assembly Services

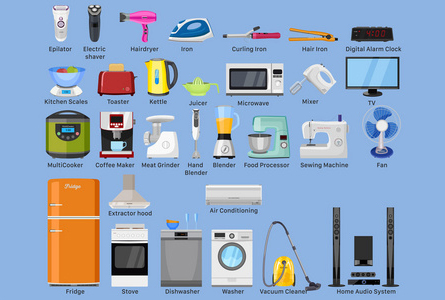

I-HiTech Circuits igxile kakhulu ekuhlinzekeni ngezinsiza zomhlangano ze-Printed Circuit Board (PCB). Lokhu kuhlanganisa umhlangano we-surface mount technology (SMT), ukuhlanganiswa kobuchwepheshe be- through-hole (THT), ukuhlanganiswa kobuchwepheshe obuxubile, ukuhlanganiswa kwe-prototype, ukukhiqizwa kwevolumu ephansi ukuya phezulu, nezixazululo ze-turnkey. Amasevisi ethu aklanyelwe ukubhekelela inhlobonhlobo yezimboni, okuhlanganisa kodwa ezingagcini nje ngezokuxhumana, izisetshenziswa zezokwelapha, ezezimoto, nogesi wabathengi.

Yebo, sinikezela ngezinsizakalo zomhlangano ze-PCB ezigcwele ze-turnkey. Lokhu kusho ukuthi singaphatha zonke izinyathelo zephrojekthi yakho kusukela ezintweni ezitholakalayo, ukwakhiwa kwe-PCB, ukuhlanganisa, ukuhlola, nokuthunyelwa kokugcina. Isixazululo sethu se-turnkey siklanyelwe ukukongela isikhathi nokunciphisa ubunzima bokuxhumana nabahlinzeki abaningi.

Nakanjani! Sihlome ngobuchwepheshe obuphambili bokukhiqiza futhi sineqembu elinamakhono elikwazi ukuphatha imihlangano ye-PCB eyinkimbinkimbi. Ukuthi iphrojekthi yakho ibandakanya ukuminyana okuphezulu kokuxhumana (i-HDI), izakhi zephimbo elihle, noma idinga amasu okunamathisela akhethekile, sinobuchwepheshe nezinsiza ukuhlangabezana nezidingo zakho.

Sisebenzisa inqubo yokuqinisekisa ikhwalithi eqinile ehlanganisa ukuhlola okuzenzakalelayo okuzenzakalelayo (i-AOI), ukuhlolwa kwe-X-ray, ukuhlolwa kwe-in-circuit (ICT), nokuhlola okusebenzayo ukuze sithole futhi silungise noma yikuphi ukukhubazeka noma izinkinga. Izinyathelo zethu zokulawula izinga ziyasebenza kuzo zonke izigaba zenqubo yokuhlanganisa ukuze siqinisekise ukuthi yonke inhlangano ye-PCB ihlangabezana nezindinganiso zethu eziphakeme kanye nezidingo zakho ezithile.

I-HiTech Circuits izibophezele ekuletheni imikhiqizo yekhwalithi ephezulu. Sigunyazwe ngaphansi kwe-ISO 9001 ngohlelo lwethu lokuphatha ikhwalithi, siqinisekisa ukuthi izinqubo zethu nemikhiqizo ihlangabezana nezindinganiso zamazwe ngamazwe zekhwalithi nokwethembeka.

Ukuze uthole isicaphuna esinemininingwane nenembile, sicela usinikeze amafayela akho okuklama e-PCB (amafayela e-Gerber, i-BOM (Umqulu Wezinto Zokusebenza), imidwebo yokuhlanganisa, nanoma yimiphi imiyalelo ethile noma izidingo onazo. Ukwengeza, imininingwane mayelana nenani nomugqa wesikhathi wephrojekthi yakho izosisiza ukuthi sikunikeze isilinganiso esinembe kakhudlwana.

Yebo, umhlangano we-PCB we-prototype ungenye yezinsizakalo zethu eziyinhloko. I-Prototyping ikuvumela ukuthi uhlole futhi ucwenge imiklamo yakho ngaphambi kokuthuthela ekukhiqizeni ngobuningi. Sikunikeza izikhathi ezisheshayo zokushintsha ama-prototypes ukusiza ukusheshisa umjikelezo wakho wokuthuthuka.

Sihlose ukunikeza izingcaphuno ngokushesha ngangokunokwenzeka. Ngokuvamile, ungalindela ukuthola ikhotheshini enemininingwane phakathi kwamahora angu-24 kuya kwangu-48 ngemva kokuhambisa wonke amadokhumenti adingekayo nolwazi mayelana nephrojekthi yakho.

Yebo, siyakuqonda ukubaluleka kokuhlangabezana neminqamulajuqu eqinile futhi singamukela ama-oda aphuthumayo omhlangano we-PCB. Sicela usithinte ngezidingo zakho ezithile, futhi sizokwenza konke okusemandleni ethu ukuhlangabezana nomugqa wakho wesikhathi ngaphandle kokuyekethisa ikhwalithi.

Sikholelwa ekugcineni amaklayenti ethu enolwazi ngazo zonke izinyathelo zendlela. Uma i-oda lakho selifakiwe, uzonikezwa umphathi wephrojekthi ozoba yindawo yakho yokuxhumana. Ungalindela izibuyekezo ezivamile mayelana nesimo se-oda lakho futhi wamukelekile ngaso sonke isikhathi ukuthintana nomphathi wephrojekthi yakho nganoma imiphi imibuzo noma izibuyekezo.

Ubuchwepheshe bethu

Kwa-XinDaChang, sisebenzisa intuthuko yakamuva kwezobuchwepheshe ukuze sihlanganise ibhodi lesifunda eliphrintiwe. Okunye nje kobuchwepheshe nemishini esiyisebenzisayo ihlanganisa:

• Umshini wokuhlanganisa amagagasi

• Khetha futhi ubeke

• I-AOI & X-Ray

• I-automated enamathelayo enamathelayo

• Umshini we-SPI

I-Surface Mount Technology assembly (SMT Assembly)

Kwa-XinDaChang, sinamandla okusebenzisa ubuchwepheshe bokukhweza phezulu ukuze sihlanganise ama-PCB akho, sisebenzisa umshini wethu wokukhetha nendawo. Sisebenzisa ubuchwepheshe bokuhlanganisa i-surface mount njengoba bubiza kakhulu futhi buthembekile kunezinye, izindlela zokuhlanganisa ze-PCB zendabuko. Isibonelo, ngokuhlanganiswa kwe-SMT ama-electronics amaningi angafakwa endaweni encane ku-PCB. Lokhu kusho ukuthi ama-PCB angenziwa ngokwezifiso kalula nangempumelelo, futhi ngevolumu ephezulu kakhulu.

Ukuhlola nokulawula ikhwalithi

Ukuqinisekisa ukuthi inqubo yokuhlanganisa i-PCB ayinawo amaphutha, sisebenzisa izindlela ezintsha zokuhlola nokuhlola i-AOI ne-X-Ray. I-AOI, noma ukuhlola okuzenzakalelayo, ukuhlola ama-PCB ngokuhluleka okuyinhlekelele kanye nokukhubazeka kwekhwalithi ngokuwaskena ngokuzenzakalelayo ngekhamera. Sisebenzisa ukuhlola okuzenzakalelayo ezigabeni eziningi zenqubo yethu yokuhlanganisa i-PCB ukuze siqinisekise ukuthi wonke ama-PCB ethu asezingeni eliphezulu kakhulu.

Flexible Volume PCB Assembly Service

Izinsizakalo zethu zomhlangano we-PCB zingaphezu kwalokho okuzokwenziwa inkampani yomhlangano we-PCB ejwayelekile. Sinikezela ngezinsizakalo ezahlukahlukene zomhlangano webhodi lesifunda ngezigaba ezahlukahlukene zokuthuthukiswa komkhiqizo wakho, okuhlanganisa:

• I-Prototype PCB Assembly: Bona ukuthi idizayini yakho ye-PCB isebenza kahle kanjani ngaphambi kokukhiqiza i-oda elikhulu. Ukuhlanganiswa kwethu kwekhwalithi ye-PCB yeprototype kusivumela ukuthi silethe isibonelo esisheshayo, ukuze ukwazi ukubona noma yiziphi izinselele ezingaba khona ekwakhiweni kwakho ngokushesha futhi wandise ikhwalithi yamabhodi akho okugcina.

• I-Low-Volume, High Mix PCB Assembly: Uma udinga inani lamabhodi ahlukene wezinhlelo zokusebenza ezikhethekile, i-HitechPCB yinkampani yakho.

• I-High-Volume PCB Assembly: Sinekhono ngokulinganayo ekukhipheni ama-oda amakhulu e-PCB njengoba siletha amancane.

• I-Consigned & Partial PCB Assembly: Amasevisi ethu omhlangano we-PCB athunyelwe ahlangabezana nezindinganiso ze-IPC Class 2 noma i-IPC class 3, aqinisekisiwe we-ISO 9001:2015 futhi athobela i-RoHS.

• I-Full Turnkey PCB Assembly: Futhi i-ISO 9001:2015-eqinisekisiwe futhi iyahambisana ne-RoHS, umhlangano wethu we-PCB we-turnkey usivumela ukuthi sinakekele yonke iphrojekthi yakho kusukela ekuqaleni kuya ekupheleni, ukuze ukwazi ukungena futhi uqale ukusizakala ngomkhiqizo osuphelile ngaso leso sikhathi.

Kusuka ku-SMD kuye kumaphrojekthi wokuhlanganisa we-PCB angena emgodini kanye nengxubevange, sikwenza konke, okuhlanganisa ukuhlola kwamahhala kwe-Valor DFM/DFA nokuhlolwa komsebenzi ukuze kuqinisekiswe ikhwalithi yamabhodi akho, ngaphandle kwezimfuneko zezindleko eziphansi noma izindleko zamathuluzi ezingeziwe lapho u-oda kabusha.

I-XinDaChang ihlanganisa izinhlelo eziqinisekisiwe ze-ISO zekhwalithi kanye nobuchwepheshe obusha bokuhlanganisa nokupakisha ukuze ilethe imikhiqizo kagesi yabathengi ehamba phambili emakethe. Ukusuka ekuhlanganisweni komkhiqizo kuya ezindaweni ezivalekile kuye ekuhlolweni nasekupakishweni, imigqa ye-SMT ye-Hitech isebenzisa ubuchwepheshe obuthuthuke kakhulu embonini okuhlanganisa:

Umhlangano we-pcb osheshayo we-Flip Chip Technologies

0201 Ubuchwepheshe

I-Lead-Free Solder Technology

Enye I-PCB Iyaphela

Ukubandakanyeka komhlinzeki kusenesikhathi

Ukwesekwa kwedizayini nobunjiniyela

Ukwakhiwa kwe-PCB kanye nomhlangano we-PCB

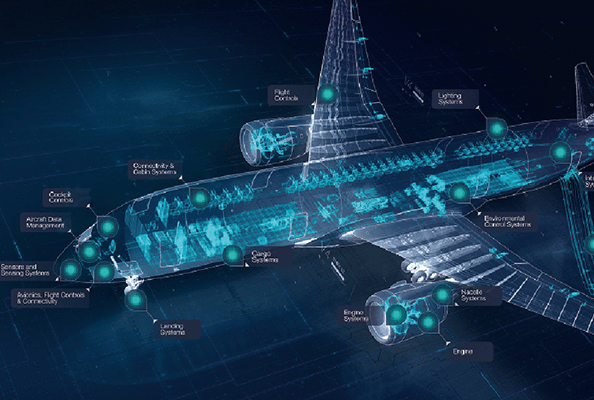

Umhlangano wendiza engemuva

Inkumbulo kanye namamojula optical

Ukuhlanganiswa kwekhebula namahhanisi

Ukubumba umjovo wepulasitiki

Ukunemba kwemishini

Izivalo

Ukuhlanganiswa kwehadiwe nesoftware

Izinsizakalo ze-BTO kanye ne-CTO ngokwezidingo zakho

Ukuhlolwa kokwethembeka

Izinqubo zekhwalithi ezinciphile neziyisithupha ze-Sigma

Uyini umehluko phakathi kwebhodi lesifunda eliphrintiwe vs PCB Assembly?

I-PCB iyibhodi lesifunda eliphrintiwe ngoba lenziwa ngokuphrinta nge-elekthronikhi, ngakho libizwa ngokuthi ibhodi lesifunda "eliphrintiwe". I-PCB iyingxenye ebalulekile ye-elekthronikhi embonini ye-elekthronikhi, iyisisekelo se-elekthronikhi. Kuwukusekelwa kwezingxenye ze-elekthronikhi kanye nesithwali sokuxhuma kagesi kwezingxenye ze-elekthronikhi. I-PCB isetshenziswe kabanzi ekukhiqizeni imikhiqizo ye-elekthronikhi.

I-PCB Assembly ngokuvamile ibhekisela ekugelezeni kokucubungula, okungabuye kuqondwe njengebhodi lesifunda eliqediwe, okungukuthi, i-PCBA ingabalwa kuphela ngemva kokuba izinqubo ze-PCB seziqediwe. I-PCB isho ibhodi lesifunda eliphrintiwe elingenalutho elingenazo izingxenye kulo. Okungenhla umehluko phakathi kwe-PCB ne-PCBA.

I-SMT (ubuchwepheshe obubekwe phezu komhlaba) kanye ne-DIP (I-Dual In-line Package) zombili izindlela zokuhlanganisa izingxenye ebhodini lesekethe. Umehluko omkhulu ukuthi i-SMT ayidingi ukubhoboza izimbobo ku-PCB, kodwa ekudiphini, idinga ukufaka iphinikhodi embobeni ebhoboziwe.

I-SMT ikakhulukazi isebenzisa umshini wokukhweza ukukhweza izingxenye ezincane nezincane ebhodini lesekethe. Inqubo yayo yokukhiqiza i-PCB positioning, ukuphrinta kwe-solder paste, ukukhwezwa ngomshini ofakayo, i-oven reflow, nokuhlola.

Idiphu “i-plug-in”, okungukuthi ukufaka izingxenye ebhodini le-PCB. Iwuhlobo lwengxenye ehlanganisiwe ye-plug-in lapho izingxenye ezithile zinkulu ngosayizi futhi zingabufanele ubuchwepheshe bokukhwezwa. Izinqubo zayo eziyinhloko zokukhiqiza ziyi-back glue, i-plug-in, ukuhlolwa, i-wave soldering, ukuxubha amapuleti, nokuhlola okuphelile.