Uma kuqhathaniswa ne-silicon-based power semiconductors, ama-semiconductors amandla e-SiC (silicon carbide) anezinzuzo eziphawulekayo ekushintsheni imvamisa, ukulahlekelwa, ukuchithwa kokushisa, i-miniaturization, njll.

Ngokukhiqizwa okukhulu kwama-silicon carbide inverters nguTesla, izinkampani eziningi seziqalile ukuletha imikhiqizo ye-silicon carbide.

I-SiC "iyamangalisa", yenziwa kanjani emhlabeni? Yiziphi izicelo manje? Asibone!

01 ☆ Ukuzalwa kwe-SiC

Njengamanye ama-semiconductors kagesi, uchungechunge lwezimboni ze-SiC-MOSFET luhlanganisai-crystal ende - substrate - epitaxy - design - production - isixhumanisi sokupakisha.

Ikristalu ende

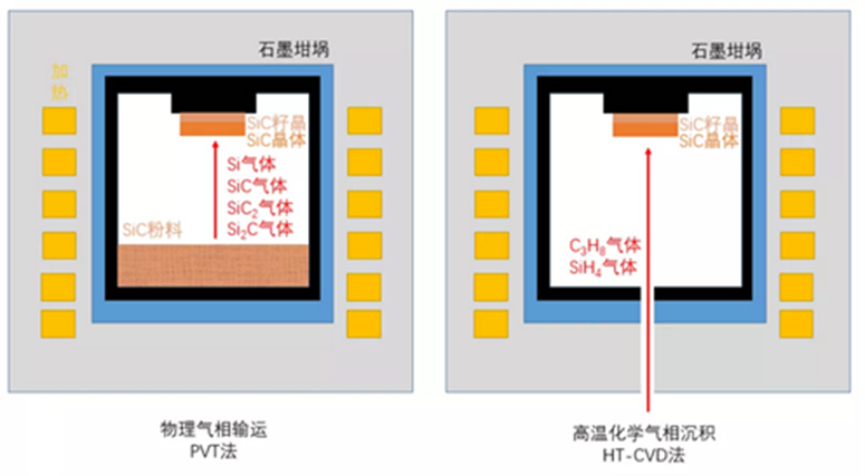

Ngesikhathi se-crystal link ende, ngokungafani nokulungiswa kwendlela ye-Tira esetshenziswa yi-silicon eyodwa ye-crystal, i-silicon carbide ithatha ngokuyinhloko indlela yokuthutha igesi ebonakalayo (i-PVT, eyaziwa nangokuthi i-Lly ethuthukisiwe noma indlela ye-seed crystal sublimation), indlela yokushisa yamakhemikhali amakhemikhali e-deposition (i-HTCVD) izithako.

☆ Isinyathelo esibalulekile

1. I-Carbonic solid material eluhlaza;

2. Ngemva kokushisa, okuqinile kwe-carbide kuba igesi;

3. Ukuhamba kwegesi ebusweni bekristalu yembewu;

4. Igesi ikhula phezu kwekristalu yembewu ibe yikristalu.

Umthombo wesithombe: "Iphuzu Lezobuchwepheshe lokuhlukanisa i-PVT ukukhula kwe-silicon carbide"

Ubuciko obuhlukile bubangele ukungalungi okukhulu okubili uma kuqhathaniswa nesisekelo se-silicon:

Okokuqala, ukukhiqiza kunzima futhi isivuno sincane.Izinga lokushisa lesigaba segesi elisuselwa kukhabhoni likhula ngaphezu kuka-2300 ° C kanti ingcindezi ingu-350MPa. Ibhokisi elimnyama lonke liyenziwa, futhi kulula ukuxutshwa ekungcoleni. Isivuno siphansi kunesisekelo se-silicon. Ubukhulu be-diameter, isivuno siyancipha.

Okwesibili ukukhula kancane.Indlela ye-Governance ye-PVT ihamba kancane, ijubane lingaba ngu-0.3-0.5mm/h, futhi ingakhula ngo-2cm ezinsukwini ezingu-7. Umkhawulo ungakhula kuphela u-3-5cm, futhi ububanzi be-crystal ingot ngokuvamile ingamayintshi angu-4 nama-intshi angu-6.

I-Silicon-based 72H ingakhula ifike ku-2-3m ubude, inobubanzi obuyiyintshi engu-6 amayintshi kanye nomthamo wokukhiqiza omusha ongu-8-intshi wamayintshi angu-12.Ngakho-ke, i-silicon carbide ivame ukubizwa ngokuthi i-crystal ingot, futhi i-silicon iba induku ye-crystal.

I-Carbide silicon crystal ingots

I-substrate

Ngemuva kokuthi i-crystal ende isiqediwe, ingena ohlelweni lokukhiqiza lwe-substrate.

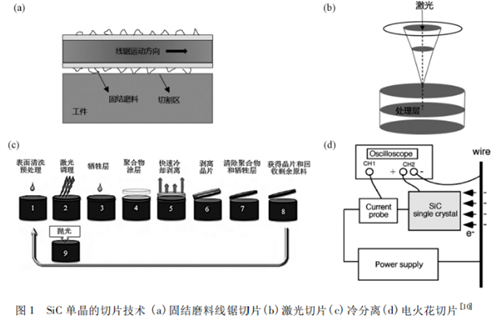

Ngemuva kokusika okuhlosiwe, ukugaya (ukugaya okungalungile, ukugaya kahle), ukupholishwa (ukupholishwa komshini), ukupholishwa kwe-ultra -precision (i-chemical mechanical polishing), i-silicon carbide substrate iyatholakala.

I-substrate idlala ikakhulukaziindima yokusekelwa ngokomzimba, ukuqhutshwa kwe-thermal kanye ne-conductivity.Ubunzima bokucubungula ukuthi impahla ye-silicon carbide iphezulu, i-crispy, futhi izinzile ezindaweni zamakhemikhali. Ngakho-ke, izindlela zokucubungula ezisekelwe ku-silicon azifanele i-silicon carbide substrate.

Izinga lomphumela wokusika lithinta ngqo ukusebenza nokusetshenziswa kahle (izindleko) zemikhiqizo ye-silicon carbide, ngakho-ke kuyadingeka ukuba kube kuncane, ukushuba okufanayo, nokusika okuphansi.

Okwamanje,4-intshi no-6-inch ikakhulukazi isebenzisa imishini yokusika enemigqa eminingi,ukusika amakristalu e-silicon abe izingcezu ezincane ezinogqinsi olungekho ngaphezu kwe-1mm.

Umdwebo wohlelo wokusika wemigqa eminingi

Ngokuzayo, ngokwanda kosayizi wama-silicon wafers, ukwanda kwezidingo zokusetshenziswa kwezinto ezibonakalayo kuzokhula, futhi ubuchwepheshe obufana nokusika i-laser nokuhlukaniswa okubandayo nakho kuzosetshenziswa kancane kancane.

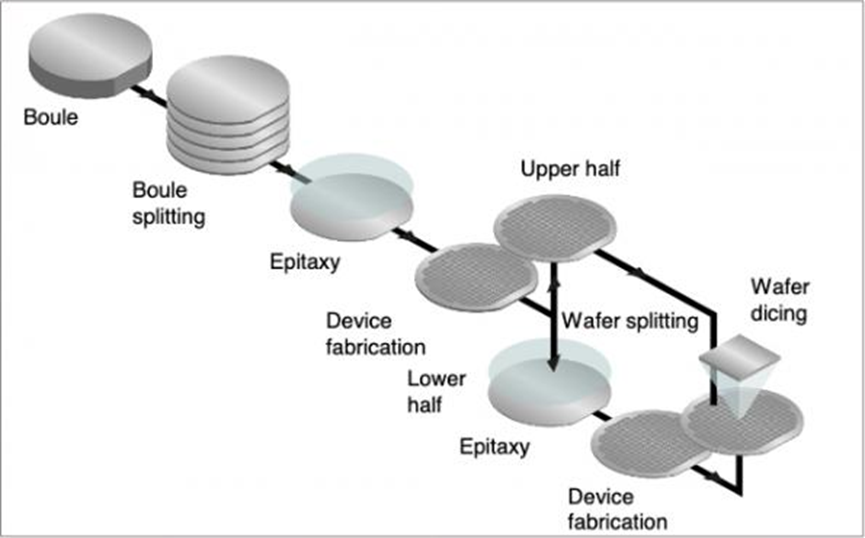

Ngo-2018, u-Infineon wathola i-Siltectra GmbH, eyathuthukisa inqubo entsha eyaziwa ngokuthi ukuqhekeka okubandayo.

Uma kuqhathaniswa nokulahleka kwenqubo yokusika yezintambo eziningi engu-1/4,inqubo yokuqhekeka okubandayo ilahlekelwe yi-1/8 yezinto ze-silicon carbide.

Isandiso

Njengoba izinto ze-silicon carbide zingakwazi ukwenza amadivaysi amandla ngqo ku-substrate, amadivaysi ahlukahlukene ayadingeka kungqimba lokunwetshwa.

Ngakho-ke, ngemva kokuqedwa kokukhiqizwa kwe-substrate, ifilimu ethile encane ye-crystal eyodwa iyakhuliswa ku-substrate ngenqubo yokwandisa.

Njengamanje, inqubo ye-chemical gas deposition method (CVD) isetshenziswa kakhulu.

Idizayini

Ngemuva kokuthi i-substrate yenziwe, ingena esigabeni sokuklama umkhiqizo.

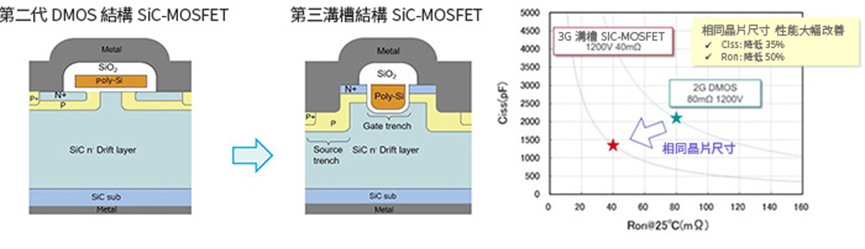

Ku-MOSFET, ukugxila kwenqubo yokuklama ukuklama kwe-groove,ngakolunye uhlangothi ukugwema ukwephulwa kwelungelo lobunikazi(I-Infineon, i-Rohm, i-ST, njll., inesakhiwo selungelo lobunikazi), futhi ngakolunye uhlangothi ukuzeukuhlangabezana nezindleko zokwenziwa kanye nokukhiqiza.

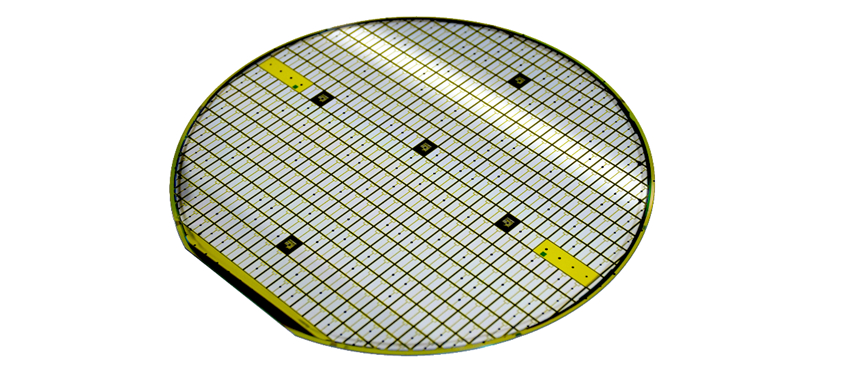

Ukwenziwa kwe-wafer

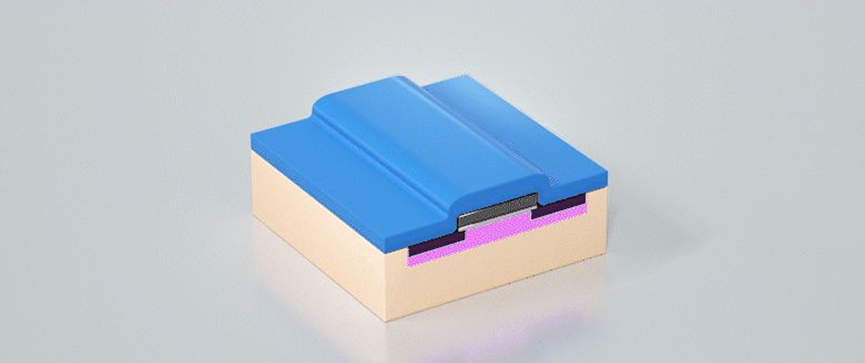

Ngemuva kokuthi umklamo womkhiqizo usuqediwe, ungena esigabeni sokukhiqiza ama-wafer,futhi inqubo icishe ifane neye-silicon, enezinyathelo ezi-5 ezilandelayo.

☆Isinyathelo 1: Jova imaski

Kwenziwa ungqimba lwefilimu ye-silicon oxide (SiO2), i-photoresist iboshwe, iphethini ye-photoresist yenziwa ngezinyathelo ze-homogenization, ukuchayeka, ukuthuthukiswa, njll., futhi isibalo sidluliselwa kufilimu ye-oxide ngenqubo yokufaka.

☆Isinyathelo sesi-2: Ukufakwa kwe-ion

Iwafa ye-silicon carbide efihliwe ifakwa kusifakeli se-ion, lapho ama-ion e-aluminium ejovwa khona ukuze akhe indawo ye-doping yohlobo lwe-P, futhi afakwe ukuze kusebenze ama-ion e-aluminium afakiwe.

Ifilimu ye-oxide iyasuswa, ama-ion e-nitrogen ajovwa endaweni ethile yesifunda se-doping sohlobo lwe-P ukuze kwakheke isifunda esihambisa amanzi sohlobo lwe-N lwe-drain kanye nomthombo, futhi ama-ion e-nitrogen afakiwe ayahoxiswa ukuze asebenze.

☆Isinyathelo sesi-3: Yenza igridi

Yenza igridi. Endaweni ephakathi komthombo kanye ne-drain, isendlalelo se-oxide yesango silungiswa ngenqubo ye-oxidation yokushisa ephezulu, futhi isendlalelo se-electrode yesango sifakwe ukuze senze isakhiwo sokulawula isango.

☆Isinyathelo sesi-4: Ukwenza izendlalelo ze-passivation

Isendlalelo se-passivation senziwe. Idiphozithi isendlalelo se-passivation esinezici ezinhle zokuvikela ukuvikela ukuwohloka kwe-interelectrode.

☆Isinyathelo sesi-5: Yenza ama-electrode omthombo wokukhipha amanzi

Yenza i-drain kanye nomthombo. Ungqimba lwe-passivation lunembobo futhi insimbi iyafafazwa ukuze yakhe i-drain kanye nomthombo.

Umthombo wesithombe: Xinxi Capital

Nakuba kunomehluko omncane phakathi kwezinga lenqubo kanye ne-silicon esekelwe, ngenxa yezimpawu zezinto ze-silicon carbide,ukufakwa kwe-ion kanye nokufakwa kwe-annealing kufanele kwenziwe endaweni yokushisa ephezulu(kufika ku-1600 ° C), izinga lokushisa eliphezulu lizothinta isakhiwo se-lattice sezinto ngokwazo, futhi ubunzima buzophinde buthinte isivuno.

Ngaphezu kwalokho, ezintweni ze-MOSFET,ikhwalithi ye-oksijeni yesango ithinta ngokuqondile ukuhamba kwesiteshi nokuthembeka kwesango, ngoba kunezinhlobo ezimbili zama-silicon nama-athomu e-carbon ku-silicon carbide material.

Ngakho-ke, indlela ekhethekile yokukhula kwesango eliphakathi iyadingeka (elinye iphuzu ukuthi ishidi le-silicon carbide lisobala, futhi ukuqondanisa isikhundla esiteji se-photolithography kunzima ku-silicon).

Ngemva kokuqedwa kokwenziwa kwe-wafer, i-chip ngayinye isikwa ibe yicwecwe elingenalutho futhi lingapakishwa ngokuvumelana nenhloso. Inqubo evamile yamadivayisi ahlukene iphakheji ye-TO.

650V CoolSiC™ MOSFETs ku-TO-247 iphakeji

Isithombe: Infineon

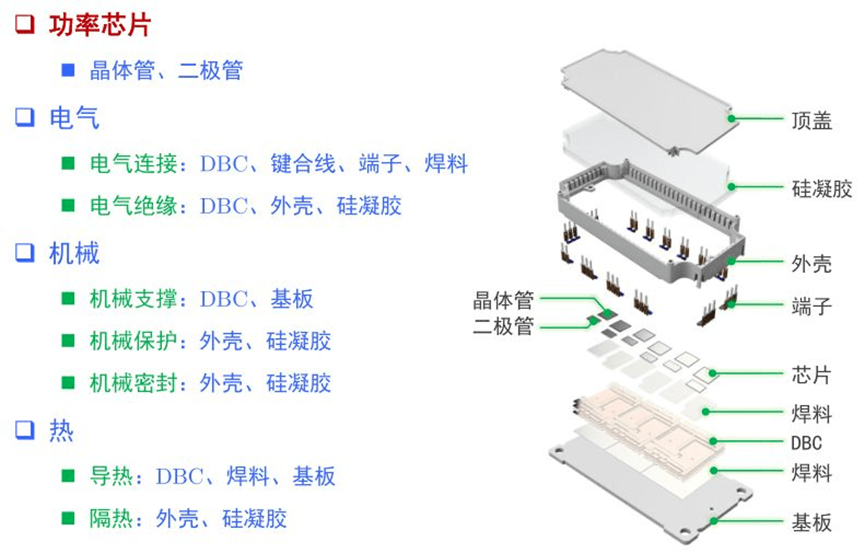

Inkambu yezimoto inamandla aphezulu kanye nezidingo zokushisa ukushisa, futhi ngezinye izikhathi kuyadingeka ukwakha ngokuqondile ama-circuits ebhuloho (ihhafu yebhuloho noma ibhuloho eligcwele, noma elihlanganiswe ngokuqondile nama-diode).

Ngakho-ke, kuvame ukupakishwa ngokuqondile kumamojula noma amasistimu. Ngokwenani lama-chips apakishwe kumojula eyodwa, ifomu elivamile ngu-1 ku-1 (BorgWarner), 6 ku-1 (Infineon), njll., futhi ezinye izinkampani zisebenzisa i-single-tube parallel scheme.

I-Borgwarner Viper

Isekela ukupholisa amanzi okunezinhlangothi ezimbili kanye ne-SiC-MOSFET

Amamojula we-Infineon CoolSiC™ MOSFET

Ngokungafani ne-silicon,amamojula e-silicon carbide asebenza ekushiseni okuphezulu, cishe ku-200 ° C.

Izinga lokushisa le-solder elithambile lendabuko liphansi, alikwazi ukuhlangabezana nezimfuneko zokushisa. Ngakho-ke, amamojula we-silicon carbide avame ukusebenzisa inqubo ye-welding yesiliva enezinga eliphansi lokushisa.

Ngemuva kokuthi imojuli isiqediwe, ingasetshenziswa ohlelweni lwezingxenye.

I-Tesla Model3 isilawuli semoto

I-chip engenalutho ivela ku-ST, iphakheji elizithuthukisile kanye nesistimu yokushayela kagesi

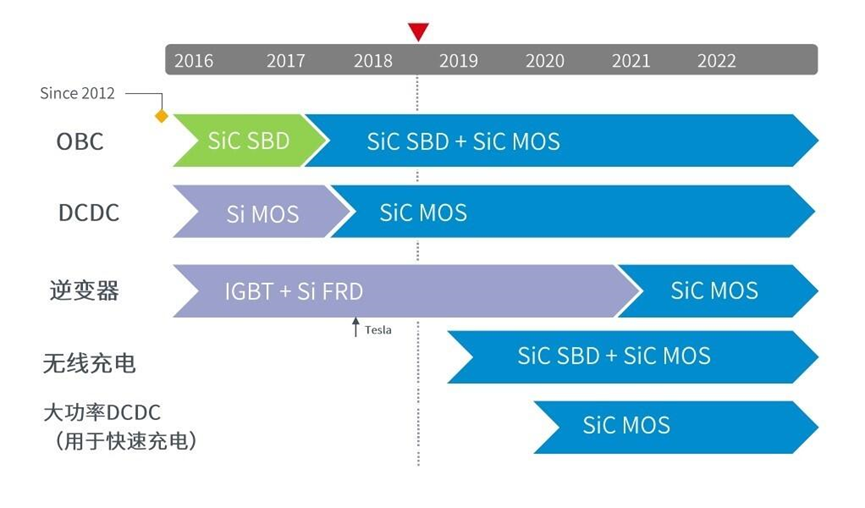

☆02 Isimo sohlelo lokusebenza lwe-SiC?

Emkhakheni wezimoto, amadivayisi kagesi asetshenziswa kakhulu kuI-DCDC, i-OBC, ama-motor inverters, ama-inverters asebenza ngogesi, ukushaja okungenantambo nezinye izingxenye.ezidinga ukuguqulwa okusheshayo kwe-AC/DC (i-DCDC ngokuyinhloko isebenza njengeswishi esheshayo).

Isithombe: BorgWarner

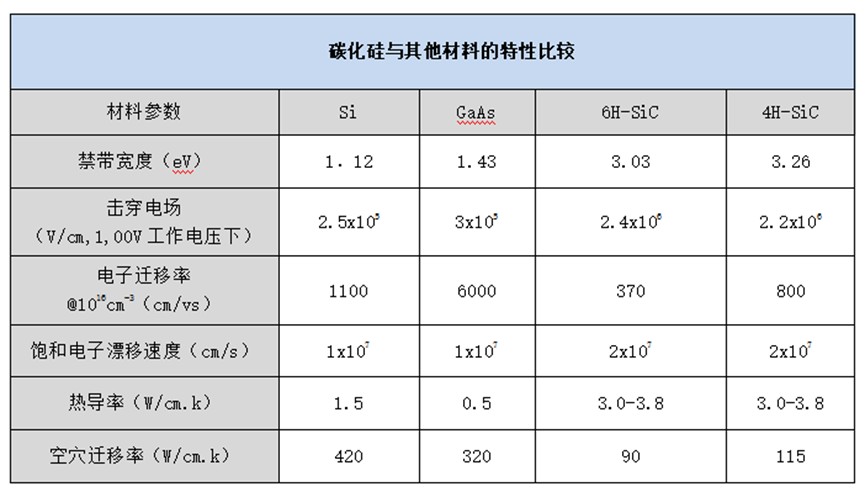

Uma kuqhathaniswa nezinto ezisekelwe ku-silicon, izinto ze-SIC ziphakemeAmandla ensimu yokuwohloka kwe-avalanche ebalulekile(3×106V/cm),ngcono conductivity ezishisayo(49W/mK) kanyeigebe lebhendi elibanzi(3.26eV).

Lapho igebe lebhendi liba banzi, liba lincane ukuvuza kwamandla kanye nokusebenza kahle kakhulu. I-conductivity engcono kakhulu ye-thermal, iyanda ukuminyana kwamanje. Ukuqina kwenkambu ye-avalanche ebalulekile, ukumelana nomthamo wedivayisi kungathuthukiswa.

Ngakho-ke, emkhakheni we-voltage ephezulu ebhodini, ama-MOSFET kanye ne-SBD alungiselelwe izinto ze-silicon carbide ukuze athathe indawo yenhlanganisela ekhona ye-IGBT ne-FRD ekhona ingathuthukisa amandla nokusebenza kahle,ikakhulukazi ezimweni zohlelo lokusebenza lwe-high frequency ukunciphisa ukulahlekelwa kokushintsha.

Njengamanje, kungenzeka kakhulu ukuthi kuzuzwe izinhlelo zokusebenza ezinkulu kuma-motor inverters, kulandele i-OBC ne-DCDC.

I-platform ye-voltage engu-800V

Ku-platform ye-voltage engu-800V, inzuzo yefrikhwensi ephezulu yenza amabhizinisi athambekele kakhulu ekukhetheni isisombululo se-SiC-MOSFET. Ngakho-ke, iningi lamanje le-800V le-electronic control planning SiC-MOSFET.

Ukuhlelwa kwezinga lenkundla kuhlanganisaI-E-GMP yesimanje, i-GM Otenergy - inkambu yokulanda, i-Porsche PPE, ne-Tesla EPA.Ngaphandle kwamamodeli enkundla ye-Porsche PPE angayiphathi ngokusobala i-SiC-MOSFET (imodeli yokuqala i-silica-based IGBT), ezinye izinkundla zezimoto zamukela izikimu ze-SiC-MOSFET.

Ipulatifomu ye-Universal Ultra energy

Ukuhlela imodeli ye-800V kungaphezulu,uhlobo lwe-Great Wall Salon i-Jiagirong, inguqulo ye-Beiqi pole Fox S HI, imoto ekahle i-S01 ne-W01, i-Xiaopeng G9, i-BMW NK1, Changan Avita E11 wathi izothwala 800V yesikhulumi, ngaphezu BYD, Lantu, GAC 'an, Mercedes-Benz, zero Run, FAW Red Flag, Volkswagen futhi wathi 800V ubuchwepheshe ocwaningweni.

Kusukela esimweni sama-oda angu-800V atholwe abahlinzeki be-Tier1,BorgWarner, Wipai Technology, ZF, United Electronics, kanye neHuichuanwonke ama-oda okushayela kagesi angu-800V amenyezelwe.

I-platform ye-voltage engu-400V

Ku-platform ye-voltage engu-400V, i-SiC-MOSFET igxile kakhulu ekucatshangweni kwamandla aphezulu kanye nokuminyana kwamandla nokusebenza kahle okuphezulu.

Njengenjini ye-Tesla Model 3\Y ekhiqizwe ngobuningi manje, amandla aphezulu enjini ye-BYD Hanhou cishe angu-200Kw (Tesla 202Kw, 194Kw, 220Kw, BYD 180Kw), i-NIO izosebenzisa nemikhiqizo ye-SiC-MOSFET eqala ngo-ET7 futhi izofakwa ohlwini lwe-ET. Amandla aphezulu ngu-240Kw (ET5 210Kw).

Ngaphezu kwalokho, ngokombono wokusebenza kahle okuphezulu, amanye amabhizinisi ahlola nokuba nokwenzeka kwemikhiqizo eyizikhukhula ye-SiC-MOSFET.

Isikhathi sokuthumela: Jul-08-2023