1. Izidingo zokubukeka nokusebenza kukagesi

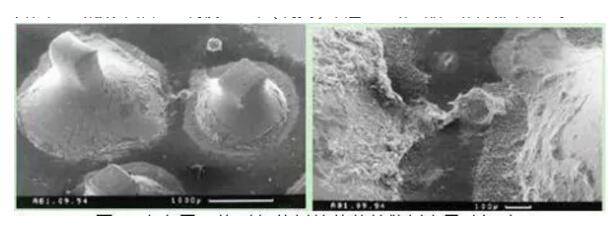

Umphumela onembile kakhulu wokungcola ku-PCBA ukubukeka kwe-PCBA. Uma ibekwe noma isetshenziswa endaweni eshisa kakhulu futhi enomswakama, kungase kube nokumuncwa komswakama kanye nezinsalela zibe mhlophe. Ngenxa yokusetshenziswa kabanzi kwama-chips angenamthofu, i-micro-BGA, iphakheji ye-chip-level (CSP) kanye nezingxenye ze-0201 ezingxenyeni, ibanga phakathi kwezingxenye nebhodi liyancipha, ubukhulu bebhodi buba buncane, futhi ukuminyana komhlangano kuyanda. Eqinisweni, uma i-halide ifihliwe ngaphansi kwengxenye noma ayikwazi ukuhlanzwa nhlobo, ukuhlanza kwendawo kungaholela emiphumeleni eyinhlekelele ngenxa yokukhululwa kwe-halide. Lokhu kungabangela nokukhula kwe-dendrite, okungaholela kumasekethe amafushane. Ukuhlanzwa okungalungile kokungcola kwe-ion kuzoholela ezinkingeni eziningi: ukumelana nendawo ephansi, ukugqwala, kanye nezinsalela ze-conductive surface kuzokwakha ukusabalalisa kwe-dendritic (dendrites) ebusweni bebhodi lesifunda, okuholela kumjikelezo omfushane wendawo, njengoba kuboniswe esithombeni.

Izinsongo eziyinhloko ekuthembekeni kwemishini yezempi ye-elekthronikhi amadevu amathini nama-intercompounds ensimbi. Inkinga isaqhubeka. Amadevu kanye ne-metal intercompounds ekugcineni kuzodala ukujikeleza okufushane. Ezindaweni ezinomswakama kanye nogesi, uma kunokungcoliswa kwe-ion eningi ezingxenyeni, kungabangela izinkinga. Isibonelo, ngenxa yokukhula kwentshebe ye-electrolytic tin, ukugqwala kwama-conductor, noma ukuncishiswa kokumelana nokufakwa kwe-insulation, izintambo ezisebhodini lesifunda zizojikeleza, njengoba kuboniswe esithombeni.

Ukuhlanzwa okungalungile kokungcola okungezona i-ionic nakho kungabangela uchungechunge lwezinkinga. Kungase kubangele ukuthi imaski yebhodi inganamatheli kahle, ukuthintana kwephini okungalungile kwesixhumi, ukuphazamiseka ngokomzimba okungekuhle, nokunamathela kabi kwento enamathelayo ezingxenyeni ezinyakazayo namapulaki. Ngesikhathi esifanayo, ukungcola okungezona i-ionic kungase futhi kufake ukungcola kwe-ionic kuyo, futhi kungase kuhlanganiswe futhi kuthwale ezinye izinsalela nezinye izinto eziyingozi. Lezi yizindaba ezingenakuzitshwa.

2, Three anti-paint enamathela izidingo

Ukwenza ukunamathela okuthembekile, ukuhlanzeka kwendawo ye-PCBA kufanele kuhlangabezane nezidingo ze-IPC-A-610E-2010 level 3 standard. Izinsalela ze-resin ezingahlanzwanga ngaphambi kokumbozwa kwendawo zingadala ukuthi ungqimba oluvikelayo lunciphe, noma luqhekeke ungqimba oluyisivikelo; Izinsalela ze-activator zingase zibangele ukufuduka kwe-electrochemical ngaphansi kwesembozo, okuholela ekuhlulekeni kokuvikela ukugqabuka kwentonga. Ucwaningo luye lwabonisa ukuthi izinga le-coating bonding lingakhuphuka ngo-50% ngokuhlanza.

3, No Ukuhlanza nakho kudinga ukuhlanzwa

Ngokwezindinganiso zamanje, igama elithi “no-clean” lisho ukuthi izinsalela ebhodini ziphephile ngamakhemikhali, ngeke zibe nomthelela ebhodini, futhi zingahlala ebhodini. Izindlela zokuhlola ezikhethekile ezifana nokutholwa kokugqwala, ukumelana nokufakwa kwe-surface insulation (SIR), i-electromigration, njll. zisetshenziswa ngokuyinhloko ukucacisa okuqukethwe kwe-halogen/halide kanjalo nokuphepha kwezingxenye ezingahlanzekile ngemva kokuhlanganiswa. Kodwa-ke, noma kusetshenziswa i-flux engahlanzekile enokuqukethwe okuqinile okuphansi, kusazoba nensalela eningi noma encane. Ngemikhiqizo enezidingo eziphezulu zokuthembeka, azikho izinsalela noma okunye ukungcola okuvunyelwe ebhodini lesifunda. Kuzicelo zamasosha, ngisho nezingxenye ze-elekthronikhi ezingahlanzekile ezingahlanzekile ziyadingeka.

Isikhathi sokuthumela: Feb-26-2024