Izinkinga ze-SMT Welding

1. PCB pad design amaphutha

Enqubweni yokuklama ye-PCB ethile, ngenxa yokuthi isikhala sincane, imbobo ingadlalwa kuphela ku-pad, kodwa i-solder paste ine-fluidity, engase ingene emgodini, okuholela ekungabikho kokunamathisela kwe-solder ku-reflow welding, ngakho-ke lapho iphini linganele ukudla ithini, kuzoholela ekushiseni okubonakalayo.

2.I-Pad surface oxidation

Ngemuva kokwenza kabusha iphedi ene-oxidized, i-reflow welding izoholela ekushiseleni okubonakalayo, ngakho-ke lapho iphedi i-oxidize, idinga ukoma kuqala. Uma i-oxidation ibucayi, idinga ukushiywa.

I-3.Izinga lokushisa lokugeleza kabusha noma isikhathi sendawo yokushisa ephezulu asanele

Ngemva kokuqedwa kwepheshi, izinga lokushisa alanele uma udlula endaweni yokushisa kabusha egeleza futhi endaweni yokushisa engashintshi, okuholela ekukhuphukeni kwethayela elincibilikayo elishisayo elingazange lenzeke ngemva kokungena endaweni yokugeleza kabusha kwezinga lokushisa eliphezulu, okuholela ekudlweni kwethini okunganele kwephini lengxenye, okuholela ekushiseleleni okubonakalayo.

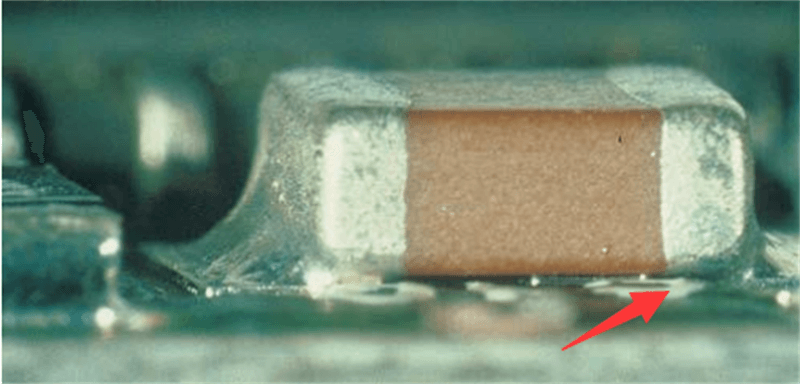

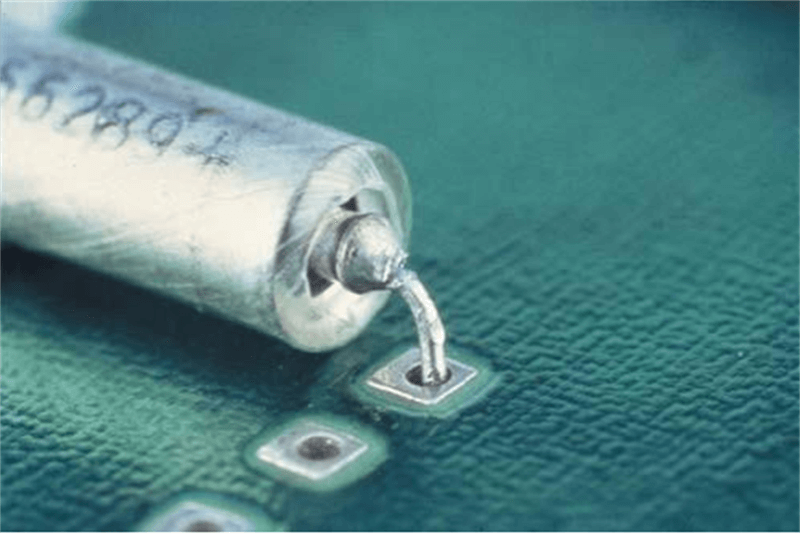

Ukuphrinta kokunamathisela kwe-Solder kuncane

Lapho ukunamathisela kwe-solder kuxutshwe, kungase kube ngenxa yokuvuleka okuncane kwensimbi yensimbi kanye nokucindezela okweqile kwe-scraper yokunyathelisa, okuholela ekuphrinteni kokunamathisela kwe-solder okuncane kanye nokushintshashintsha okusheshayo kwe-solder paste ye-reflow welding, okuholela ekushiseni okubonakalayo.

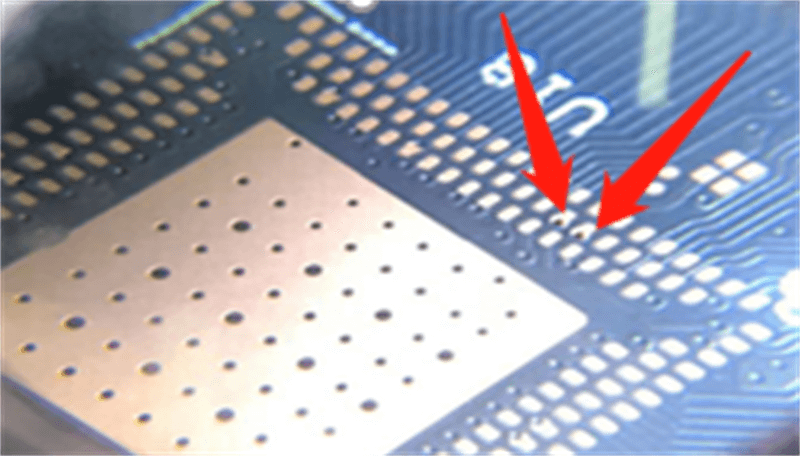

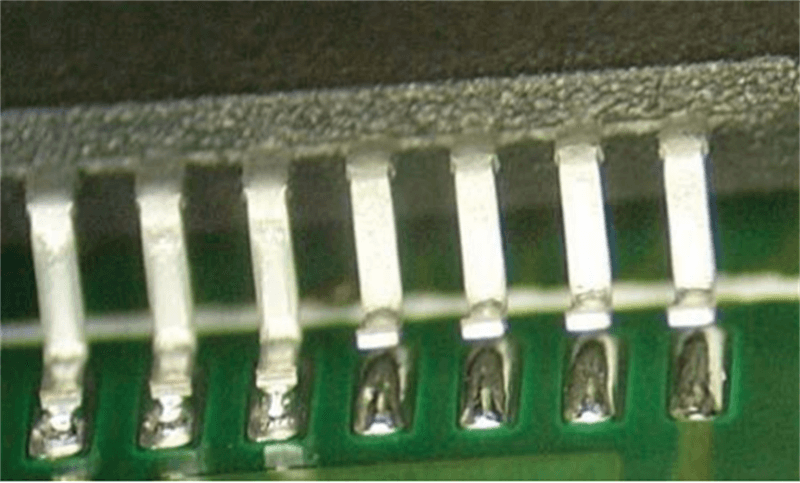

5.Amadivayisi anephini eliphezulu

Uma idivayisi ye-high-pin kuyi-SMT, kungase kube ukuthi ngenxa yesizathu esithile, ingxenye ikhubazekile, ibhodi le-PCB ligobile, noma ukucindezela okungalungile komshini wokubeka akwanele, okuholela ekuncibilikeni okuhlukahlukene okushisayo kwe-solder, okuholela ekushiseni okubonakalayo.

Izizathu zokushisela ze-DIP ezibonakalayo

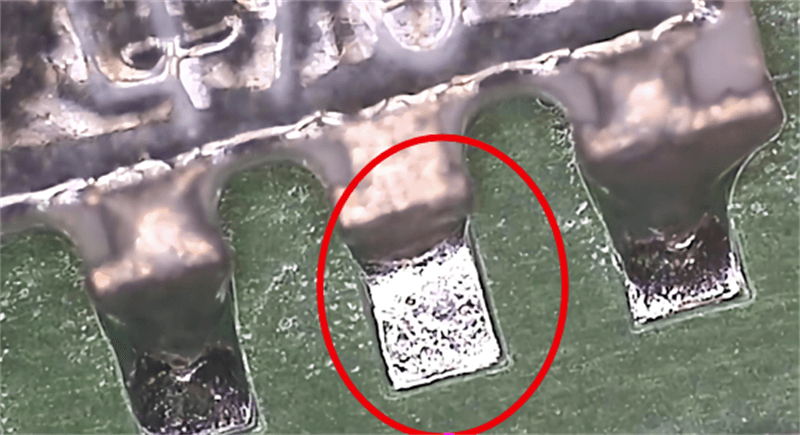

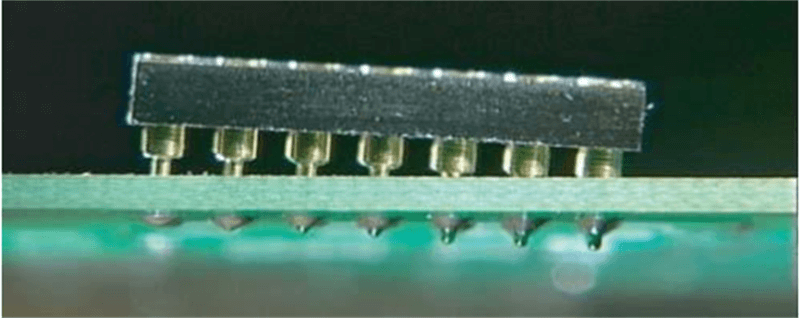

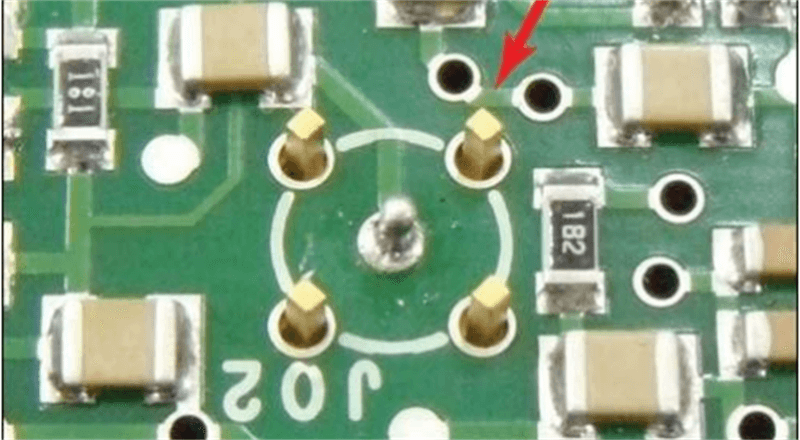

1.PCB plug-in imbobo amaphutha design

Imbobo yokufakwa kwe-PCB, ukubekezelelana kuphakathi kuka-±0.075mm, imbobo yokupakisha ye-PCB inkulu kunephinikhodi yedivayisi ephathekayo, idivayisi izobe ixega, okuholela ethini elinganele, i-welding ebonakalayo noma i-air welding nezinye izinkinga zekhwalithi.

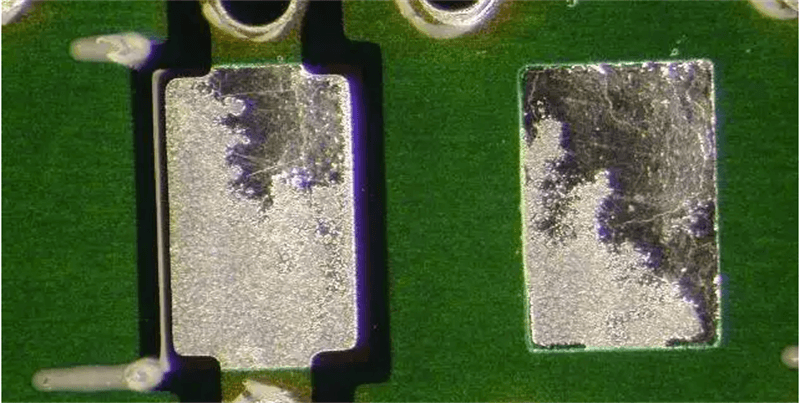

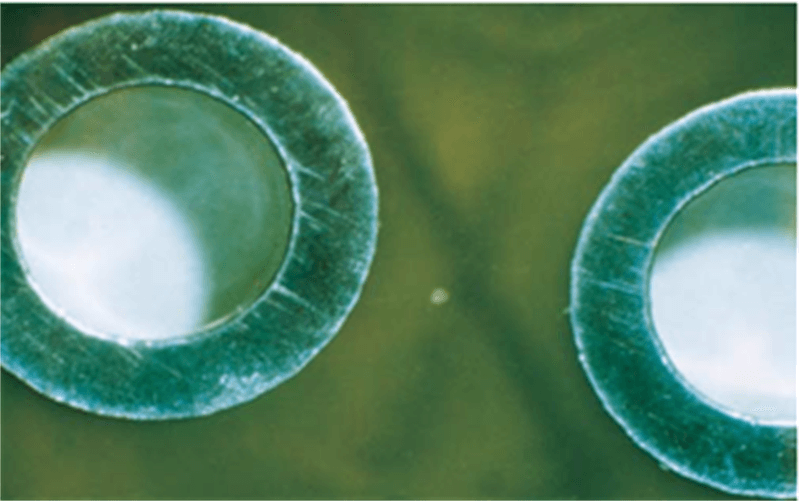

2.Iphedi kanye ne-oxidation yembobo

Izimbobo zamaphedi e-PCB zingcolile, zine-oxidized, noma zingcoliswe izinto ezebiwe, amafutha, amabala omjuluko, njll., okuzoholela ekushindelekeni okubi noma nokungashiseli, okuholela ekushiseleni okubonakalayo kanye nokushisela emoyeni.

3.PCB ibhodi kanye nezici zekhwalithi yedivayisi

Amabhodi e-PCB athengiwe, izakhi nokunye ukuthengiselana akufanelekile, akukho ukuhlolwa okuqinile kokwamukela okwenziwe, futhi kunezinkinga zekhwalithi ezifana nokushisela okubonakalayo ngesikhathi somhlangano.

4.PCB ibhodi kanye idivayisi kuphelelwe yisikhathi

Amabhodi e-PCB athengiwe kanye nezingxenye, ngenxa yenkathi yokusungula yinde kakhulu, ethintwa imvelo yeshede, njengezinga lokushisa, umswakama noma amagesi abolayo, okuholela ezenzweni zokushisela ezifana nokushisela okubonakalayo.

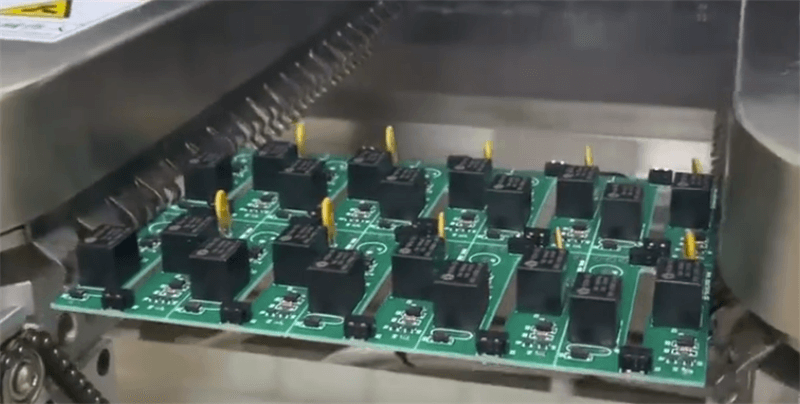

5.Izici zemishini yokunamathisela amagagasi

Ukushisa okuphezulu esithandweni somlilo we-wave kuholela ekusheshisweni kwe-oxidation yezinto ze-solder kanye nobuso bezinto eziyisisekelo, okuholela ekunciphiseni ukunamathela kobuso kuzinto ze-solder eziwuketshezi. Ngaphezu kwalokho, izinga lokushisa eliphezulu liphinde ligxumeke indawo embi kakhulu yesisekelo, okuholela ekwehleni kwesenzo se-capillary kanye nokungahlangani kahle, okuholela ekushiseleleni okubonakalayo.

Isikhathi sokuthumela: Jul-11-2023