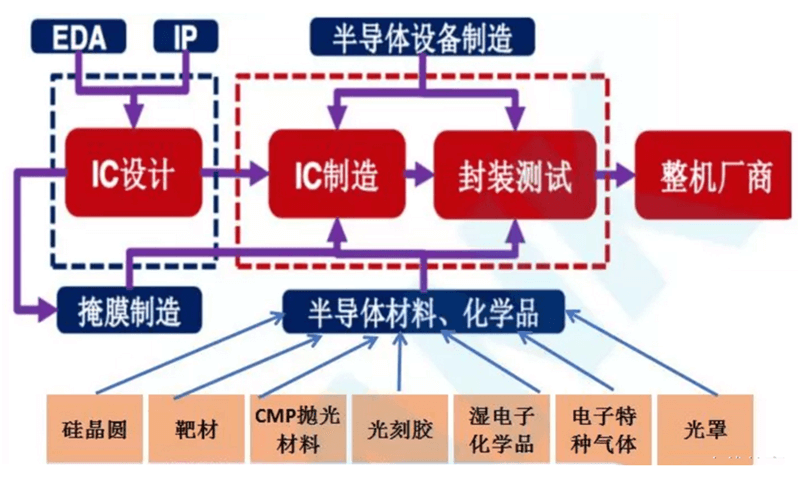

Ngokombono wochwepheshe, inqubo yokukhiqiza i-chip iyinkimbinkimbi kakhulu futhi iyakhathaza. Nokho, kusukela ochungechungeni oluphelele lwezimboni lwe-IC, ihlukaniswe ikakhulukazi izingxenye ezine: Idizayini ye-IC → ukukhiqiza kwe-IC → ukupakisha → ukuhlola.

Inqubo yokukhiqiza i-chip:

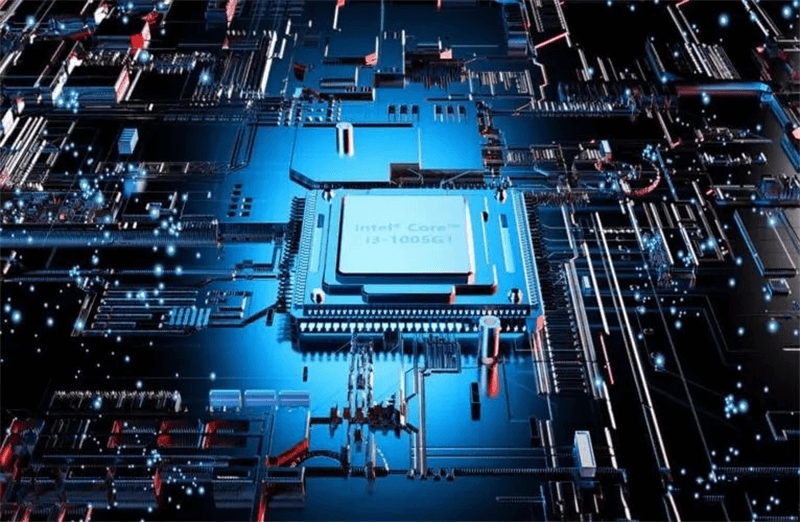

1. I-chip design

I-chip iwumkhiqizo onevolumu encane kodwa enemba kakhulu. Ukwenza i-chip, ukuklama yingxenye yokuqala. Idizayini idinga usizo lwedizayini ye-chip yedizayini ye-chip edingekayo ukuze icutshungulwe ngosizo lwethuluzi le-EDA namanye ama-IP cores.

Inqubo yokukhiqiza i-chip:

1. I-chip design

I-chip iwumkhiqizo onevolumu encane kodwa enemba kakhulu. Ukwenza i-chip, ukuklama yingxenye yokuqala. Idizayini idinga usizo lwedizayini ye-chip yedizayini ye-chip edingekayo ukuze icutshungulwe ngosizo lwethuluzi le-EDA namanye ama-IP cores.

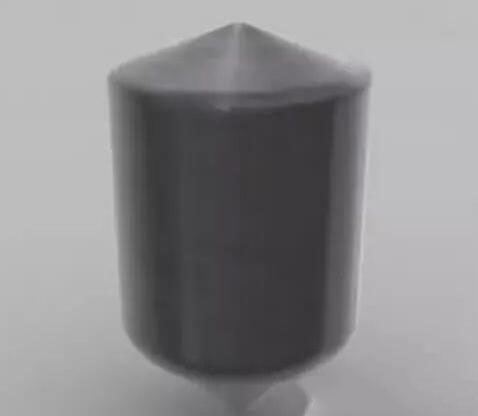

3. I-Silicon -ukuphakamisa

Ngemuva kokuhlukaniswa kwe-silicon, izinto ezisele ziyashiywa. I-silicon ehlanzekile ngemuva kwezinyathelo eziningi isifinyelele ikhwalithi yokukhiqiza i-semiconductor. Lokhu kubizwa ngokuthi i-silicon ye-electronic.

4. I-Silicon-casting ingots

Ngemuva kokuhlanza, i-silicon kufanele iphonswe kuma-ingots we-silicon. Ikristalu eyodwa ye-silicon ye-electronic-grade ngemuva kokuphonswa ku-ingot inesisindo esingaba ngu-100 kg, futhi ubumsulwa be-silicon bufinyelela ku-99.9999%.

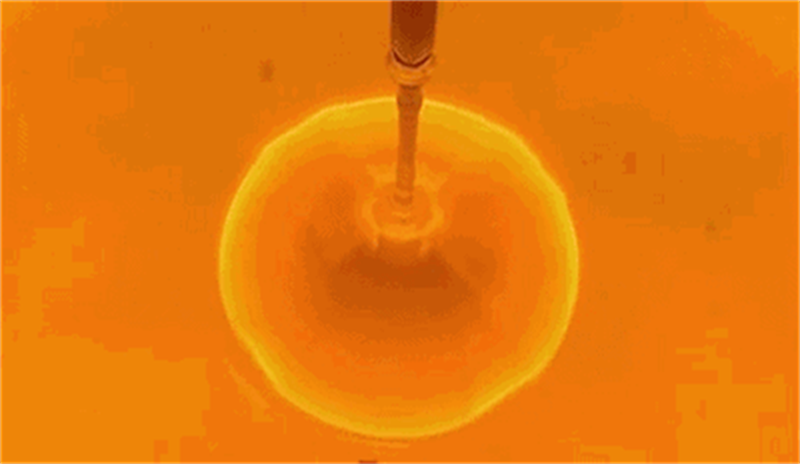

5. Ukucubungula ifayela

Ngemuva kokuthi i-silicon ingot isiphonswe, yonke ingot ye-silicon kufanele isikwe ibe yizicucu, okuyi-wafer esivame ukuyibiza ngokuthi i-wafer, encane kakhulu. Kamuva, i-wafer ipholishwa ize iphelele, futhi ubuso bushelelezi njengesibuko.

Ububanzi bama-silicon wafers bungama-intshi angu-8 (200mm) no-12-intshi (300mm) ububanzi. Uma ubukhulu be-diameter buba bukhulu, kunciphisa izindleko ze-chip eyodwa, kodwa buphakama ubunzima bokucubungula.

5. Ukucubungula ifayela

Ngemuva kokuthi i-silicon ingot isiphonswe, yonke ingot ye-silicon kufanele isikwe ibe yizicucu, okuyi-wafer esivame ukuyibiza ngokuthi i-wafer, encane kakhulu. Kamuva, i-wafer ipholishwa ize iphelele, futhi ubuso bushelelezi njengesibuko.

Ububanzi bama-silicon wafers bungama-intshi angu-8 (200mm) no-12-intshi (300mm) ububanzi. Uma ubukhulu be-diameter buba bukhulu, kunciphisa izindleko ze-chip eyodwa, kodwa buphakama ubunzima bokucubungula.

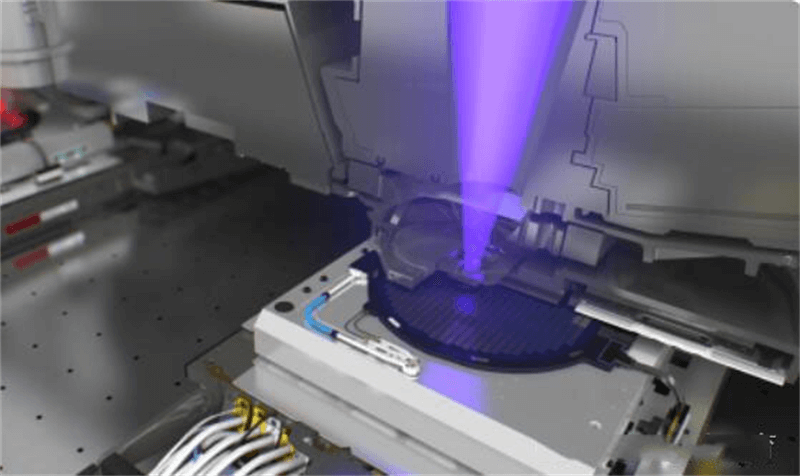

7. I-Eclipse kanye nomjovo we-ion

Okokuqala, kuyadingeka ukugqwala i-silicon oxide ne-silicon nitride evezwe ngaphandle kwe-photoresist, futhi kuncishiswe ungqimba lwe-silicon ukuze luvale phakathi kweshubhu le-crystal, bese usebenzisa ubuchwepheshe bokufaka ukuveza i-silicon engezansi. Bese ujova i-boron noma i-phosphorus esakhiweni se-silicon, bese ugcwalisa ithusi ukuze uxhumane namanye ama-transistors, bese usebenzisa enye ingqimba yeglue kuwo ukuze wenze ungqimba lwesakhiwo. Ngokuvamile, i-chip iqukethe inqwaba yezendlalelo, njengothelawayeka ominyene.

7. I-Eclipse kanye nomjovo we-ion

Okokuqala, kuyadingeka ukugqwala i-silicon oxide ne-silicon nitride evezwe ngaphandle kwe-photoresist, futhi kuncishiswe ungqimba lwe-silicon ukuze luvale phakathi kweshubhu le-crystal, bese usebenzisa ubuchwepheshe bokufaka ukuveza i-silicon engezansi. Bese ujova i-boron noma i-phosphorus esakhiweni se-silicon, bese ugcwalisa ithusi ukuze uxhumane namanye ama-transistors, bese usebenzisa enye ingqimba yeglue kuwo ukuze wenze ungqimba lwesakhiwo. Ngokuvamile, i-chip iqukethe inqwaba yezendlalelo, njengothelawayeka ominyene.

Isikhathi sokuthumela: Jul-08-2023