I-PCB multilayer compaction iyinqubo elandelanayo. Lokhu kusho ukuthi isisekelo se- layering sizoba ucezu lwe-copper foil enongqimba lwe-prepreg ebekwe phezulu. Inani lezendlalelo ze-prepreg liyahlukahluka ngokuya ngezidingo zokusebenza. Ngaphezu kwalokho, i-internal core ifakwa kungqimba lwe-prepreg billet bese igcwaliswa ngokuqhubekayo ngelendlalelo ye-prepreg billet embozwe nge-foil yethusi. I-laminate ye-PCB enezingqimba eziningi yenziwa kanjalo. Beka ama-laminates afanayo phezulu komunye nomunye. Ngemva kokwengezwa kwe-foil yokugcina, kwakhiwa isitaki sokugcina, esibizwa ngokuthi "incwadi," futhi isitaki ngasinye sibizwa ngokuthi "isahluko."

Lapho incwadi isiqediwe, idluliselwa emshinini wokunyathelisa we-hydraulic. I-hydraulic press iyashisisa futhi ifaka inani elikhulu lokucindezela kanye ne-vacuum encwadini. Le nqubo ibizwa ngokuthi ukuphulukisa ngoba ivimbela ukuthintana phakathi kwama-laminates nomunye nomunye futhi ivumela i-resin prepreg ukuthi ihlangane nomnyombo kanye ne-foil. Izingxenye zibe sezikhishwa futhi zipholiswe ekamelweni lokushisa ukuze kuvunyelwe inhlaka ukuthi ihlale, ngaleyo ndlela kuphothulwe ukukhiqizwa kokukhiqizwa kwe-PCB ye-copper multilayer.

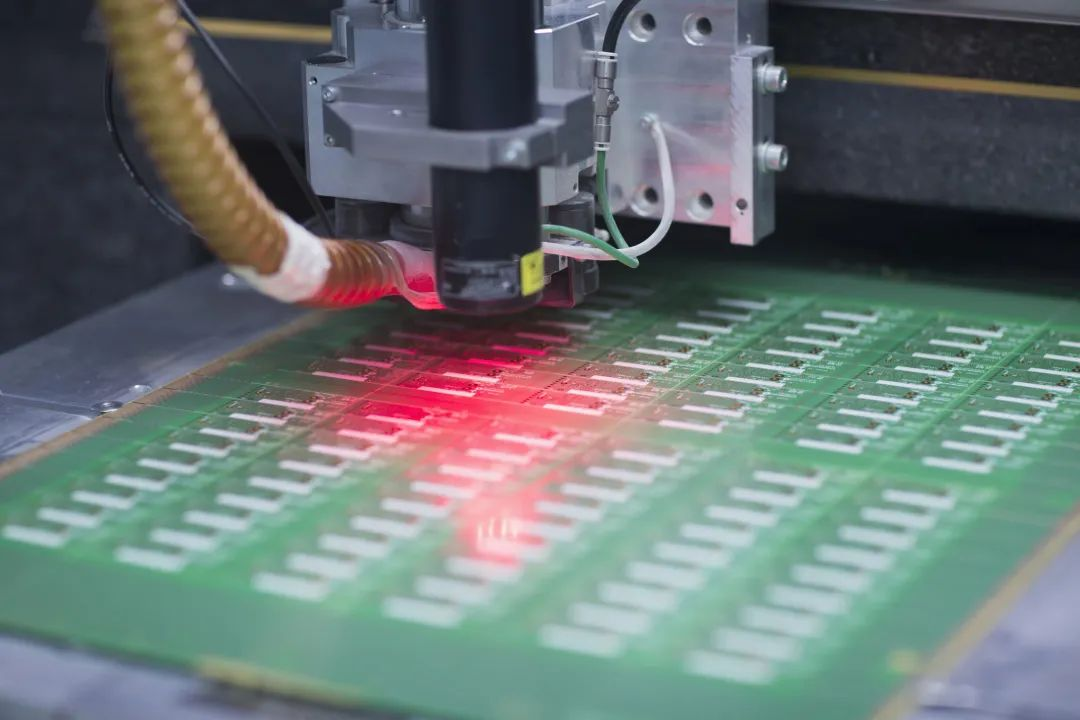

Ngemuva kokuthi amashidi ahlukene wezinto eziluhlaza esikiwe ngokusho kosayizi obaluliwe, inani elihlukile lamashidi likhethwa ngokusho kobukhulu beshidi ukwenza i-slab, futhi i-slab laminated ihlanganiswe kuyunithi yokucindezela ngokuvumelana nokulandelana kwezidingo zenqubo. Phusha iyunithi yokucindezela emshinini wokugcwalisa ukuze ucindezele futhi wenze.

Izigaba ezi-5 zokulawula izinga lokushisa

(a) Isiteji sokushisa: izinga lokushisa lisuka ekamelweni kuya ekushiseni kokuqala kokusabela kokwelapha okungaphezulu, kuyilapho i-resin yongqimba ewumgogodla ishisisiwe, ingxenye yezinto eziguquguqukayo iyakhishwa, futhi ingcindezi ingu-1/3 kuya ku-1/2 wengqikithi yokucindezela.

(b) Isiteji sokufakelwa: i-surface layer resin yelashwa ngesilinganiso esiphansi sokusabela. I-core layer resin iyashisisa futhi incibilike ngokufanayo, futhi ukuxhumana kwesendlalelo se-resin kuqala ukuhlangana.

(c) Isiteji sokushisa: kusukela ekushiseni kokuqala kokuphulukisa kuya kumazinga okushisa aphezulu ashiwo ngesikhathi sokucindezela, isivinini sokushisa akufanele sisheshe kakhulu, ngaphandle kwalokho isivinini sokuphulukisa sengqimba engaphezulu sizoshesha kakhulu, futhi asikwazi ukuhlanganiswa kahle ne-core layer resin, okuholela ekuhlukaniseni noma ekuqhekekeni komkhiqizo ophelile.

(d) izinga lokushisa elingaguquki: lapho izinga lokushisa lifinyelela inani eliphakeme kakhulu lokugcina izinga elingaguquki, indima yalesi sigaba iwukuqinisekisa ukuthi inhlaka yongqimba olungaphezulu yelapheke ngokuphelele, inhlaka yongqimba ewumgogodla yenziwe ipulasitiki ngendlela efanayo, nokuqinisekisa inhlanganisela yokuncibilika phakathi kwezingqimba zamashidi wezinto ezibonakalayo, ngaphansi kwesenzo sokucindezela ukuze ulenze libe yingxenye eminyene ngokuphelele, bese ukusebenza komkhiqizo ophelile ukuze kuzuzwe inani elingcono kakhulu.

(e) Isiteji sokupholisa: Uma i-resin yongqimba oluphakathi nendawo ye-slab seyelaphekile ngokugcwele futhi yahlanganiswa ngokugcwele ne-core layer resin, ingapholiswa futhi ipholiswe, futhi indlela yokupholisa iwukudlulisa amanzi okupholisa epuletini elishisayo lomshini wokunyathelisa, nalo elingapholiswa ngokwemvelo. Lesi sigaba kufanele senziwe ngaphansi kokugcinwa kokucindezela okucacisiwe, futhi izinga lokupholisa elifanele kufanele lilawulwe. Lapho izinga lokushisa lepuleti lehla ngaphansi kwezinga lokushisa elifanele, ukukhululwa kwengcindezi kungenziwa.

Isikhathi sokuthumela: Mar-07-2024