Ngesikhathi senqubo yokukhiqiza amabhodi e-PCB, izimo eziningi ezingalindelekile zizokwenzeka, njengethusi elenziwe nge-electroplated, i-chemical copper plating, i-golden plating, i-tin-lead alloy plating nokunye ukufakwa kwe-delamination kongqimba. Ngakho siyini isizathu salokhu kuhlukaniswa?

Ngaphansi kwemisebe yokukhanya kwe-ultraviolet, i-photoinitiator emunca amandla okukhanya iboliswa ibe yiqembu lamahhala eliqala ukusabela kwe-photopolymerization bese lenza i-molecule yomzimba engancibiliki kusixazululo se-alkali esincibilikayo. Ngaphansi kokuchayeka, ngenxa ye-polymerization engaphelele, ngesikhathi senqubo yokuthuthukiswa, ukuvuvukala kwefilimu nokuthambisa, okuholela emigqeni engacacile ngisho nefilimu ewela phansi, okuholela ekuxhumaneni okubi phakathi kwefilimu nethusi; Uma ukuchayeka kudlulele, kuzodala ubunzima ekuthuthukisweni, futhi kuzophinde kukhiqize i-warping kanye nokuxebuka ngesikhathi senqubo yokucwenga, kwenze i-infiltration plating. Ngakho-ke kubalulekile ukulawula amandla okuchayeka; Ngemuva kokuba ubuso bethusi buphathwe, isikhathi sokuhlanza akulula ukuba side kakhulu, ngoba amanzi okuhlanza aqukethe inani elithile lezinto ezine-acidic, nakuba okuqukethwe kwayo kubuthakathaka, kodwa umthelela ebusweni bethusi awukwazi ukuthathwa kalula, futhi umsebenzi wokuhlanza kufanele uqhutshwe ngokuhambisana ngokuqinile nezincazelo zenqubo.

Isizathu esiyinhloko sokuthi kungani ungqimba lwegolide liwe phezu kongqimba lwe-nickel ukwelapha okungaphezulu kwe-nickel. Umsebenzi ophansi we-nickel metal kunzima ukuthola imiphumela egculisayo. Ingaphezulu le-nickel coating kulula ukukhiqiza ifilimu ye-passivation emoyeni, njengokwelashwa okungalungile, izohlukanisa ungqimba lwegolide ebusweni bongqimba lwe-nickel. Uma ukwenza kusebenze kungafanele ku-electroplating, ungqimba lwegolide luzosuswa ebusweni bongqimba lwe-nickel bese lucwecwa. Isizathu sesibili ukuthi ngemva kokwenza kusebenze, isikhathi sokuhlanza side kakhulu, okwenza ifilimu ye-passivation iphinde yakhiwe endaweni ye-nickel, bese ifakwa ngegolide, okuzokwenza nakanjani kukhiqize amaphutha ekuhlanganiseni.

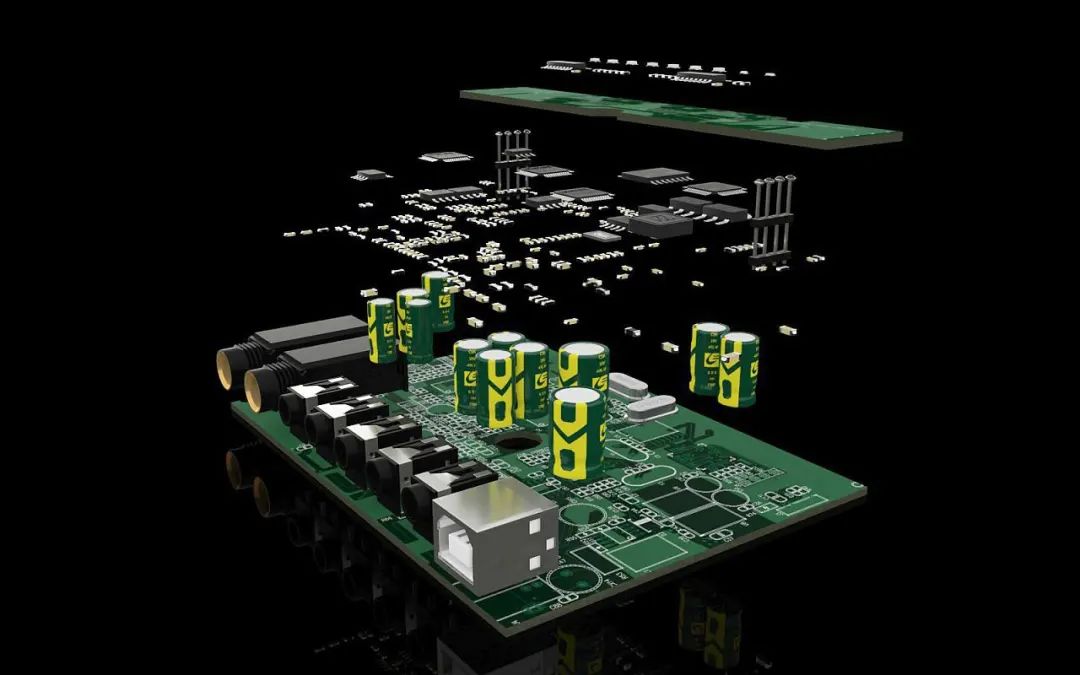

Kunezizathu eziningi ze-plating delamination, uma ufuna ukwenza isimo esifanayo ohlelweni lokukhiqiza ipuleti singenzeki, sinokuhlobana okubalulekile nokunakekelwa kanye nesibopho sochwepheshe. Ngakho-ke, umkhiqizi we-PCB osezingeni eliphezulu uzoqhuba ukuqeqeshwa okusezingeni eliphezulu kwawo wonke umsebenzi waseshabhu ukuze kuvinjelwe ukulethwa kwemikhiqizo esezingeni eliphansi.

Isikhathi sokuthumela: Apr-07-2024