Kungani ufunde ukwakheka kwesekethe yamandla

Isifunda sokuphakelwa kwamandla siyingxenye ebalulekile yomkhiqizo we-elekthronikhi, ukuklanywa kwesifunda sokuphakelwa kwamandla kuhlobene ngokuqondile nokusebenza komkhiqizo.

Ukuhlukaniswa kwamasekhethi okuphakela amandla

Amasekhethi kagesi emikhiqizo yethu ye-elekthronikhi ikakhulukazi ahlanganisa amandla alayini kanye nempahla yamandla yokushintsha imvamisa ephezulu. Ngokombono, ukunikezwa kwamandla omugqa ukuthi kungakanani okwamanje okudingwa ngumsebenzisi, okokufaka kuzonikeza ukuthi angakanani amanje; Ukushintsha ukunikezwa kwamandla ukuthi mangakanani amandla adingwa ngumsebenzisi, futhi angakanani amandla anikezwa ekugcineni kokufaka.

Umdwebo wohlelo wesekethe yokuphakelwa kwamandla olayini

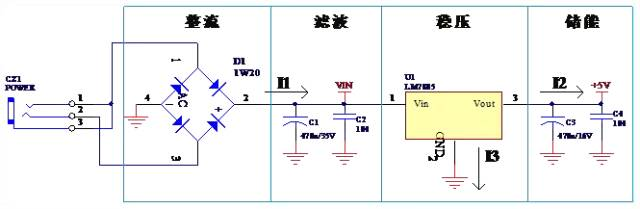

Amadivayisi kagesi olayini asebenza esimweni somugqa, njengama-chips ethu asetshenziswa kakhulu okulawula amandla kagesi LM7805, LM317, SPX1117 njalonjalo. Umfanekiso 1 ngezansi umdwebo wohlelo lwesekethe yokuphakelwa kwamandla elawulwayo i-LM7805.

Umfanekiso 1 Umdwebo weSkimu wokuphakelwa kwamandla omugqa

Kungabonakala emfanekisweni ukuthi ukunikezwa kwamandla omugqa kwakhiwe izingxenye ezisebenzayo ezifana nokulungisa, ukuhlunga, ukulawulwa kwamandla kagesi kanye nokugcinwa kwamandla. Ngesikhathi esifanayo, ukunikezwa kwamandla okujwayelekile komugqa kuwuchungechunge lwamandla okulawulwa kwamandla kagesi, ukuphuma kwamanje kulingana nokufakwayo kwamanje, i-I1=I2+I3, i-I3 isiphetho sereferensi, yamanje incane kakhulu, ngakho-ke I1≈I3. Kungani sifuna ukukhuluma ngezamanje, ngoba umklamo we-PCB, ububanzi bomugqa ngamunye abubekwa ngokungahleliwe, kufanele kunqunywe ngokuhambisana nobukhulu bamanje phakathi kwama-nodes kuhlelo. Usayizi wamanje nokugeleza kwamanje kufanele kucace ukwenza ibhodi libe lilungile.

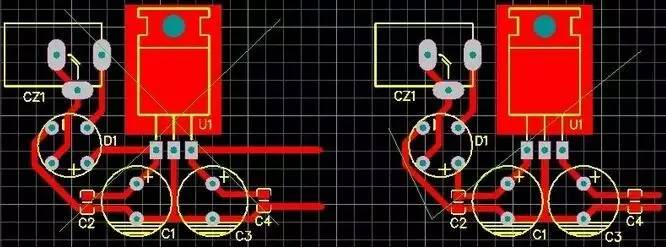

Umdwebo we-PCB wokuphakela amandla olayini

Lapho uklama i-PCB, ukwakheka kwezingxenye kufanele kuhlangane, konke ukuxhumana kufanele kube kufushane ngangokunokwenzeka, futhi izingxenye nemigqa kufanele kubekwe ngokuhambisana nobudlelwano obusebenzayo bezingxenye zohlelo. Lo mdwebo wokunikezwa kwamandla uwukulungiswa kokuqala, bese ukuhlunga, ukuhlunga kungumthetho we-voltage, ukulawulwa kwamandla kagesi kuyi-capacitor yokugcina amandla, ngemva kokugeleza nge-capacitor kuya kugesi wesifunda olandelayo.

Umfanekiso 2 wumdwebo we-PCB womdwebo wohlelo olungenhla, futhi imidwebo emibili iyefana. Isithombe esingakwesokunxele nesithombe esifanele sihluke kancane, amandla atholakala esithombeni kwesokunxele aqonde ngqo onyaweni lokufakwayo lwe-chip yesilawuli se-voltage ngemva kokulungiswa, bese kuba i-voltage regulator capacitor, lapho umphumela wokuhlunga we-capacitor mubi kakhulu, futhi okukhiphayo nakho kuyinkinga. Isithombe esingakwesokudla sihle. Akumele nje sicabangele ukugeleza kwenkinga yokuphakelwa kwamandla okuhle, kodwa futhi kufanele sicabangele inkinga yokubuyela emuva, ngokuvamile, intambo kagesi ekahle kanye nolayini wokubuyela emuva komhlaba kufanele kusondelene ngangokunokwenzeka.

Umfanekiso 2 we-PCB we-linear power supply

Lapho siklama i-PCB yokunikeza amandla omugqa, kufanele futhi sinake inkinga yokushisa ukushisa kwe-chip yokulawula amandla omugqa wamandla, ukuthi ukushisa kuza kanjani, uma i-voltage regulator chip front end ingu-10V, isiphetho esiphumayo singu-5V, kanti okukhiphayo kwamanje ngu-500mA, khona-ke kukhona ukwehla kwamandla kagesi angu-5V ku-chip yokulawula; Uma i-voltage yokufaka ingu-15V, ukwehla kwamandla kagesi kungu-10V, futhi ukushisa okukhiqiziwe kungu-5W, ngakho-ke, sidinga ukubekela eceleni isikhala esanele sokulahla ukushisa noma usinki wokushisa onengqondo ngokuvumelana namandla okukhipha ukushisa. Ukunikezwa kwamandla kalayini ngokuvamile kusetshenziswa ezimeni lapho umehluko wengcindezi umncane uma kuqhathaniswa futhi owamanje umncane uma kuqhathaniswa, ngaphandle kwalokho, sicela usebenzise isifunda sokuphakelwa kwamandla.

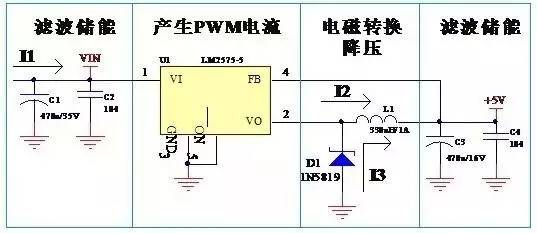

Isibonelo seskimu sokushintsha imvamisa yokunikezwa kwamandla kagesi

Ukushintsha ukunikezwa kwamandla ukusebenzisa isifunda ukuze ulawule ishubhu lokushintsha ukuvala nokunqanyulwa kwesivinini esikhulu, ukukhiqiza i-waveform ye-PWM, ngokusebenzisa i-inductor kanye ne-diode yamanje eqhubekayo, ukusetshenziswa kokuguqulwa kwe-electromagnetic kwendlela yokulawula i-voltage. Ukushintsha ukunikezwa kwamandla, ukusebenza kahle okuphezulu, ukushisa okuphansi, ngokuvamile sisebenzisa isifunda: LM2575, MC34063, SP6659 njalonjalo. Ngokombono, ukunikezwa kwamandla okushintshwa kuyalingana kuzo zombili iziphetho zesekethe, i-voltage ihambisana ngokuphambene, futhi yamanje ilingana ngokuphambene.

Umfanekiso 3 Umdwebo weSikimu we-LM2575 eshintsha isekethe yokuphakelwa kwamandla

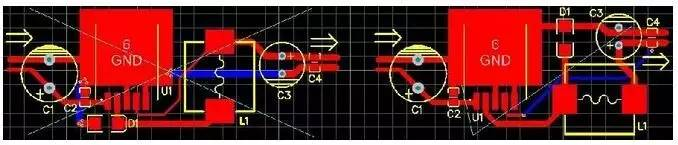

Umdwebo we-PCB wokushintsha ukunikezwa kwamandla

Lapho uklama i-PCB yokushintsha kwamandla kagesi, kuyadingeka ukuthi unake: indawo yokufaka yomugqa wempendulo kanye ne-diode yamanje eqhubekayo inikezwa yona i-current eqhubekayo. Njengoba kungabonwa ku-Figure 3, uma i-U1 ivuliwe, i-I2 yamanje ingena ku-inductor L1. Isici se-inductor siwukuthi lapho i-current igeleza nge-inductor, ayikwazi ukukhiqizwa ngokuzumayo, futhi ayikwazi ukunyamalala ngokuzumayo. Ushintsho lwamanje ku-inductor lunenqubo yesikhathi. Ngaphansi kwesenzo se-pulsed yamanje i-I2 egeleza nge-inductance, amanye amandla kagesi aguqulwa abe amandla kazibuthe, futhi okwamanje ayanda kancane kancane, ngesikhathi esithile, isifunda sokulawula i-U1 sivala i-I2, ngenxa yezimpawu ze-inductance, yamanje ayikwazi ukunyamalala ngokuzumayo, ngalesi sikhathi i-diode isebenza, ithatha i-I2 yamanje, ngakho-ke ibizwa ngokuthi i-continuous diode yamanje, i-diode eqhubekayo ingabonwa. inductance. I-I3 yamanje eqhubekayo iqala kusukela ekugcineni okungalungile kwe-C3 futhi igeleza ekugcineni okuhle kwe-C3 nge-D1 ne-L1, okulingana nepompo, isebenzisa amandla e-inductor ukwandisa i-voltage ye-capacitor C3. Kuphinde kube nenkinga yephoyinti lokufaka lomugqa wempendulo wokutholwa kwe-voltage, okufanele ibuyiselwe endaweni ngemva kokuhlunga, ngaphandle kwalokho i-ripple ye-voltage ephumayo izoba nkulu. Lawa maphuzu amabili avame ukushaywa indiva abaningi abaklami bethu be-PCB, becabanga ukuthi inethiwekhi efanayo ayifani lapho, empeleni, indawo ayifani, futhi umthelela wokusebenza mkhulu. Umfanekiso wesi-4 wumdwebo we-PCB we-LM2575 eshintsha amandla kagesi. Ake sibone ukuthi yini engalungile ngomdwebo ongalungile.

Umfanekiso 4 we-PCB we-LM2575 eshintsha ukunikezwa kwamandla

Kungani sifuna ukukhuluma ngesimiso sohlelo ngokuningiliziwe, ngoba i-schematic iqukethe ulwazi oluningi lwe-PCB, njengendawo yokufinyelela yephinikhodi yengxenye, usayizi wamanje wenethiwekhi ye-node, njll., bheka i-schematic, i-PCB design akuyona inkinga. Amasekhethi e-LM7805 kanye ne-LM2575 amele isifunda sesakhiwo esijwayelekile sokuphakelwa kwamandla omugqa kanye nokushintsha kwamandla kagesi, ngokulandelana. Lapho wenza i-PCBS, ukwakheka kanye nezintambo zale midwebo emibili ye-PCB kuqondile kulayini, kodwa imikhiqizo ihlukile futhi ibhodi lesifunda lihlukile, elilungiswa ngokuvumelana nesimo sangempela.

Zonke izinguquko azihlukaniseki, ngakho-ke isimiso sokujikeleza kwamandla kanye nendlela ibhodi linjalo ngayo, futhi yonke imikhiqizo ye-elekthronikhi ayinakuhlukaniswa nokunikezwa kwamandla kanye nesifunda sayo, ngakho-ke, funda izifunda ezimbili, enye nayo iqondwa.

Isikhathi sokuthumela: Jul-04-2023