Ukukhethwa kwezinto ze-PCB nezingxenye ze-elekthronikhi kufundwa impela, ngoba amakhasimende adinga ukucabangela izinto eziningi, njengezinkomba zokusebenza kwezingxenye, imisebenzi, kanye nekhwalithi kanye nebanga lezingxenye.

Namuhla, sizokwethula ngendlela ehlelekile indlela yokukhetha izinto zokwakha ze-PCB nezinto zikagesi.

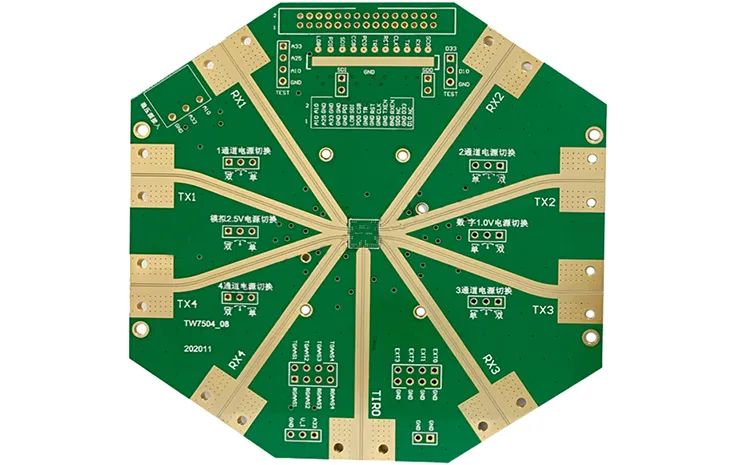

Ukukhetha impahla ye-PCB

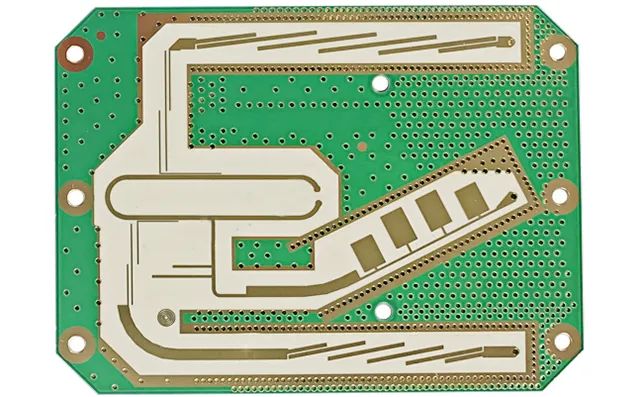

Ukusula kwe-FR4 epoxy fiberglass kusetshenziselwa imikhiqizo ye-elekthronikhi, ukusula kwe-polyimide fiberglass kusetshenziselwa amazinga okushisa aphezulu noma amabhodi esekethe aguquguqukayo, kanye nokusula kwe-polytetrafluoroethylene fiberglass kuyadingeka kumasekhethi anemvamisa ephezulu. Ngemikhiqizo ye-elekthronikhi enezidingo zokushisa okuphezulu, ama-substrates ensimbi kufanele asetshenziswe.

Izinto okufanele zicatshangelwe lapho kukhethwa izinto ze-PCB:

(1) I-substrate enezinga lokushisa eliphezulu lokushintsha kwengilazi (Tg) kufanele ikhethwe ngokufanelekile, futhi i-Tg kufanele ibe ngaphezu kwezinga lokushisa lokusebenza kwesekethe.

(2) I-coefficient ephansi yokunwetshwa kwe-thermal (CTE) iyadingeka. Ngenxa yokungaguquki kwe-coefficient yokwanda okushisayo ngaku-X, Y nogqinsi, kulula ukubangela ukuwohloka kwe-PCB, futhi kuzobangela ukuphuka kwembobo ye-metallization kanye nezingxenye zokulimala ezimweni ezimbi kakhulu.

(3) Ukumelana nokushisa okuphezulu kuyadingeka. Ngokuvamile, i-PCB iyadingeka ukuthi ibe nokumelana nokushisa okungu-250 ℃ / 50S.

(4) Kudingeka ukucaba okuhle. Isidingo sekhasi le-PCB le-warpage le-SMT ngu-<0.0075mm/mm.

(5) Mayelana nokusebenza kukagesi, amasekhethi aphezulu adinga ukukhethwa kwezinto ezinokulahleka okuphezulu kwe-dielectric kanye nokulahleka kwe-dielectric ephansi. Ukumelana ne-insulation, amandla kagesi, ukumelana ne-arc ukuhlangabezana nezidingo zomkhiqizo.

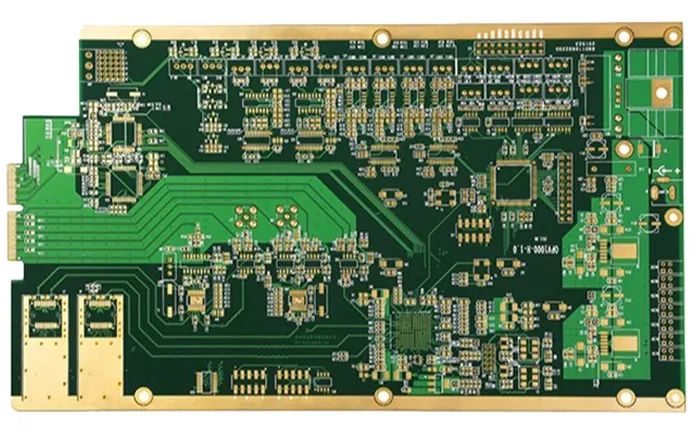

Ukukhethwa kwezingxenye ze-elekthronikhi

Ngaphezu kokuhlangabezana nezidingo zokusebenza kukagesi, ukukhethwa kwezingxenye kufanele futhi kuhlangabezane nezidingo zokuhlangana kwendawo yezingxenye. Kodwa futhi ngokuya ngemibandela yemishini yokukhiqiza umugqa kanye nenqubo yomkhiqizo ukukhetha ifomu lokupakisha lengxenye, usayizi wengxenye, ifomu lokupakisha lengxenye.

Isibonelo, lapho ukuhlangana okuphezulu kudinga ukukhethwa kwezingxenye ezincane ezinosayizi omncane: uma umshini ofakayo ungenayo i-feeder ye-braid ebanzi, idivayisi ye-SMD yokupakishwa kwe-braid ayikwazi ukukhethwa;

Isikhathi sokuthumela: Jan-22-2024