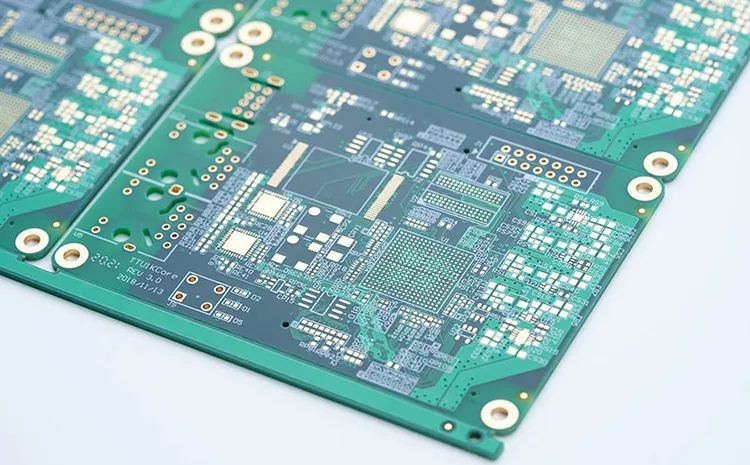

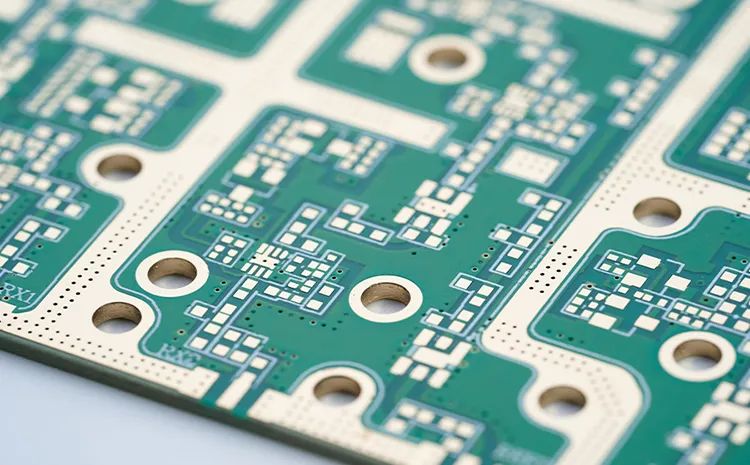

I-PCB ngenxa yokunemba nokuqina kwayo, izidingo zempilo yezemvelo kuwo wonke ama-workshop we-PCB ziphezulu kakhulu, futhi ezinye izinkundla zokuxhumana zivezwa “nokukhanya okuphuzi” usuku lonke. Umswakama, futhi ungenye yezinkomba ezidinga ukulawulwa ngokuqinile, namuhla sizokhuluma ngomthelela womswakama ku-PCBA.

“Umswakama” obalulekile

Umswakama uyinkomba ebaluleke kakhulu futhi elawulwa ngokuqinile enqubweni yokukhiqiza. Umswakama ophansi ungase ubangele ukoma, ukwanda kwe-ESD, ukukhuphuka kwamazinga othuli, ukuvaleka kalula kokuvuleka kwezifanekiso, nokwenyuka kokugqoka kwesifanekiso. Ukuzijwayeza kufakazele ukuthi umswakama ophansi uzothinta ngqo futhi unciphise umthamo wokukhiqiza. Ukuphakama kakhulu kuzodala ukuthi okokusebenza kudonse umswakama, okuholela e-delamination, imiphumela ye-popcorn, namabhola e-solder. Umswakama ubuye wehlise inani le-TG lezinto ezibonakalayo futhi ukhuphule i-warping eguqukayo ngesikhathi sokushisela.

Isingeniso kumswakama ongaphezulu

Cishe zonke izindawo eziqinile (njengensimbi, ingilazi, izitsha zobumba, i-silicon, njll.) zinongqimba olumanzi olumunca amanzi (ungqimba olulodwa noma olunamangqamuzana amaningi) olubonakala lapho izinga lokushisa elingaphezulu lilingana nezinga lokushisa lezinga lamazolo lomoya ozungezile (kuye ngokuthi izinga lokushisa, umswakama, nomfutho womoya). Ukungqubuzana phakathi kwensimbi nensimbi kuyenyuka ngokuncipha komswakamo, futhi kumswakama olinganiselwe ongu-20% RH nangaphansi, ukungqubuzana kuphakeme ngokuphindwe izikhathi ezingu-1.5 kunomswakama ohlobene ongu-80% RH.

Izimbotshana ezimunca umswakama noma umswakama (ama-epoxy resins, amapulasitiki, ama-fluxes, njll.) zivame ukumunca lezi zingqimba ezimuncayo, futhi ngisho nalapho izinga lokushisa elingaphezulu lingaphansi kwendawo yamazolo (i-condensation), ungqimba olumuncayo oluqukethe amanzi alubonakali ebusweni bento.

Ngamanzi asezingqimbeni ezimunca i-molecule eyodwa kulezi zindawo angena ku-plastic encapsulation device (MSD), futhi lapho izendlalelo ezimunca i-molecule eyodwa zisondela ezingqimbeni ezingama-20 ngogqinsi, umswakama omuncwa yilezi zendlalelo ezimunca i-molecule eyodwa ekugcineni udala umphumela we-popcorn ngesikhathi sokuphinda kufakwe i-soldering.

Umthelela womswakama ngesikhathi sokukhiqiza

Umswakamo unemiphumela eminingi ekukhiqizeni nasekukhiqizeni. Ngokuvamile, umswakama awubonakali (ngaphandle kwesisindo esikhulayo), kodwa imiphumela iyizimbotshana, ama-voids, i-solder spatter, amabhola e-solder, nama-voids angaphansi.

Kunoma iyiphi inqubo, ukulawulwa komswakama nomswakama kubaluleke kakhulu, uma ukubonakala kwendawo yomzimba kungavamile, umkhiqizo ophelile awufaneleki. Ngakho-ke, i-workshop evamile kufanele iqinisekise ukuthi umswakama kanye nomswakama we-substrate surface kulawulwa kahle ukuze kuqinisekiswe ukuthi izinkomba zemvelo ohlelweni lokukhiqiza umkhiqizo oqediwe zingaphakathi kwebanga elishiwo.

Isikhathi sokuthumela: Mar-26-2024