Ukuhlelwa okunengqondo kwezingxenye ze-elekthronikhi ebhodini le-PCB kuyisixhumanisi esibaluleke kakhulu sokunciphisa ukukhubazeka kokushisela! Izingxenye kufanele zigweme izindawo ezinamavelu amakhulu kakhulu okuchezuka kanye nezindawo zokucindezeleka okukhulu kwangaphakathi ngangokunokwenzeka, futhi isakhiwo kufanele silingane ngangokunokwenzeka.

Ukuze kwandiswe ukusetshenziswa kwesikhala sebhodi lesifunda, ngikholelwa ukuthi abalingani abaningi bokuklama bazozama ukubeka izingxenye ngokumelene nomkhawulo webhodi, kodwa empeleni, lo mkhuba uzoletha ubunzima obukhulu ekukhiqizeni kanye nomhlangano we-PCBA, futhi kuholele ekungakwazini ukushisela umhlangano oh!

Namuhla, ake sikhulume ngesakhiwo sedivayisi enqenqemeni ngokuningiliziwe

Ingozi yesakhiwo sedivayisi eseceleni kwephaneli

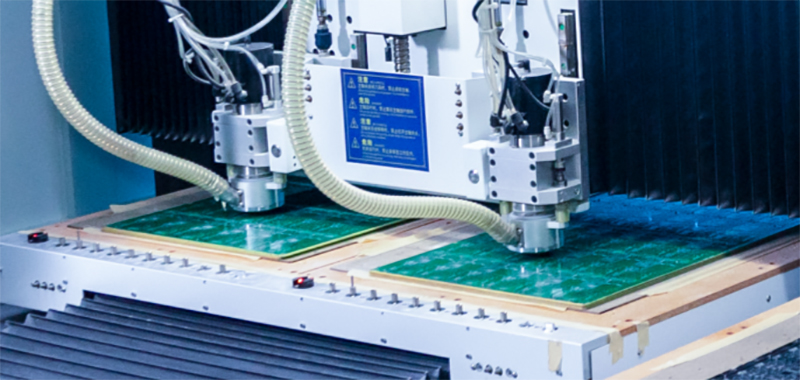

01. Ibhodi lokubumba onqenqemeni lokugaya ibhodi

Uma izingxenye zibekwe eduze kakhulu nomkhawulo wepuleti, i-welding pad yezingxenye izokhishwa lapho kwakhiwa ipuleti yokugaya. Ngokuvamile, ibanga eliphakathi kwephedi lokushisela kanye nonqenqema kufanele libe likhulu kuno-0.2mm, ngaphandle kwalokho i-welding pad yedivayisi enqenqemeni izokhishwa futhi umhlangano ongemuva awukwazi ukushisela izingxenye.

02. Ukwakha ipuleti onqenqemeni V-CUT

Uma unqenqema lwepuleti luyi-V-CUT kaMose, izingxenye zidinga ukuba kude nomkhawulo wepuleti, ngoba ummese we-V-CUT osuka phakathi kwepuleti ngokuvamile ungaphezu kuka-0.4mm kude nomkhawulo we-V-CUT, ngaphandle kwalokho ummese we-V-CUT uzolimaza ipuleti yokushisela, okuholela ekutheni izingxenye azikwazi ukushiswa.

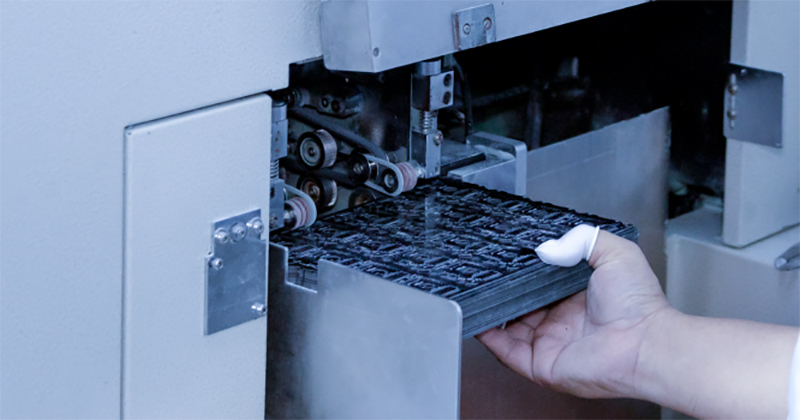

03. Imishini yokugxambukela kwengxenye

Ukuhlelwa kwezingxenye ezisondele kakhulu emaphethelweni epuleti ngesikhathi sokuklama kungase kuphazamise ukusebenza kwemishini yokuhlanganisa okuzenzakalelayo, njengemishini ye-wave-soldering noma i-reflow welding, lapho ihlanganisa izingxenye.

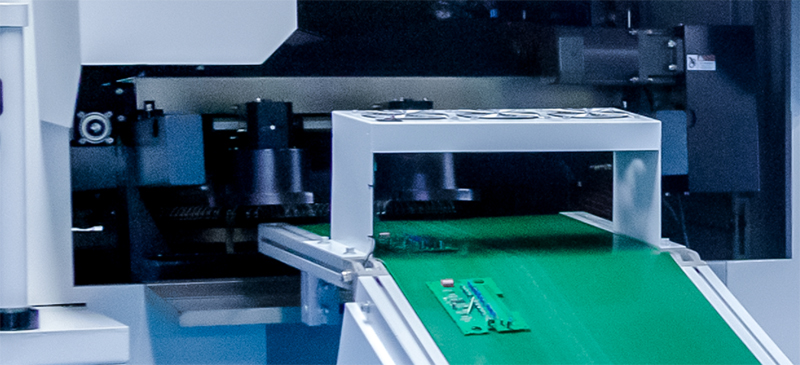

04. Idivayisi iphahlazeka ezingxenyeni

Lapho ingxenye isondela emaphethelweni ebhodi, amandla ayo amakhulu okuphazamisa idivayisi ehlanganisiwe. Isibonelo, izingxenye ezifana nama-electrolytic capacitors amakhulu, amade, kufanele abekwe kude nomkhawulo webhodi kunezinye izingxenye.

05. Izingxenye zebhodi elincane zonakele

Ngemuva kokuthi umhlangano womkhiqizo usuqediwe, umkhiqizo osikiwe udinga ukuhlukaniswa nepuleti. Phakathi nokuhlukaniswa, izingxenye ezisondele kakhulu onqenqemeni zingase zonakaliswe, ezingase zibe nezikhawu futhi kube nzima ukuzibona futhi zilungise.

Okulandelayo ukwabelana ngekesi lokukhiqiza mayelana nebanga ledivayisi enqenqemeni alanele, okuholela ekulimaleni kuwe ~

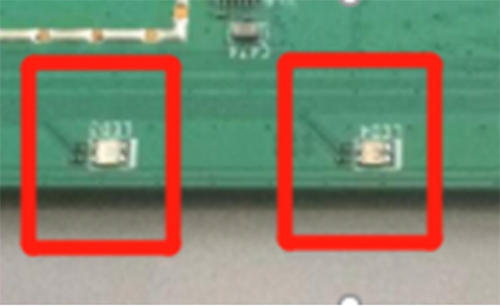

Incazelo yenkinga

Kutholakala ukuthi isibani se-LED somkhiqizo siseduze nonqenqema lwebhodi lapho i-SMT ibekwa, okulula ukushaywa ngayo ekukhiqizeni.

Umthelela wenkinga

Ukukhiqizwa nokuthutha, kanye nesibani se-LED kuzophulwa lapho inqubo ye-DIP idlula ithrekhi, ezothinta umsebenzi womkhiqizo.

Isandiso senkinga

Kuyadingeka ukushintsha ibhodi bese uhambisa i-LED ngaphakathi kwebhodi. Ngesikhathi esifanayo, kuzophinde kubandakanye ukuguqulwa kwekholomu yomhlahlandlela wokukhanya kwesakhiwo, okubangela ukubambezeleka okukhulu emjikelezweni wokuthuthukiswa kwephrojekthi.

Ukutholwa kwengozi yamadivayisi asemaphethelweni

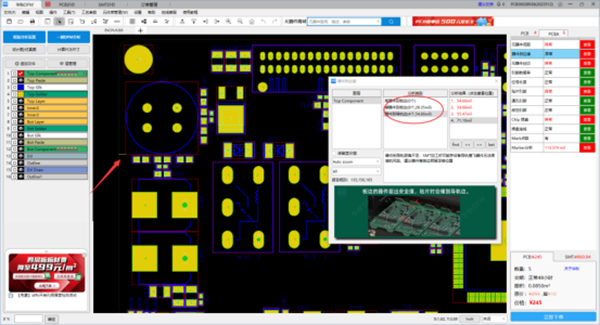

Ukubaluleka kokuklama kwengxenye kuyabonakala, ukukhanya kuzothinta i-welding, okusindayo kuzoholela ngokuqondile emonakalweni wedivayisi, ngakho-ke ungaqinisekisa kanjani izinkinga zokuklama ezingu-0, bese uqedela ngempumelelo ukukhiqiza?

Ngomsebenzi wokuhlanganisa nokuhlaziya, I-BEST ingachaza imithetho yokuhlola ngokuya ngemingcele yebanga ukusuka onqenqemeni lohlobo lwengxenye. Iphinde ibe nezinto zokuhlola ezikhethekile zesakhiwo sezingxenye zonqenqema lwepuleti, okuhlanganisa izinto eziningi zokuhlola ezinemininingwane eminingi njengedivayisi ephezulu ukuya onqenqemeni lwepuleti, idivayisi ephansi ukuya onqenqemeni lwepuleti, kanye nedivayisi eya onqenqemeni lwesitimela somhlahlandlela womshini, ongahlangabezana ngokugcwele nezidingo zokuklama zokuhlolwa kwebanga eliphephile ledivayisi ukusuka onqenqemeni lwepuleti.

Isikhathi sokuthumela: Apr-17-2023