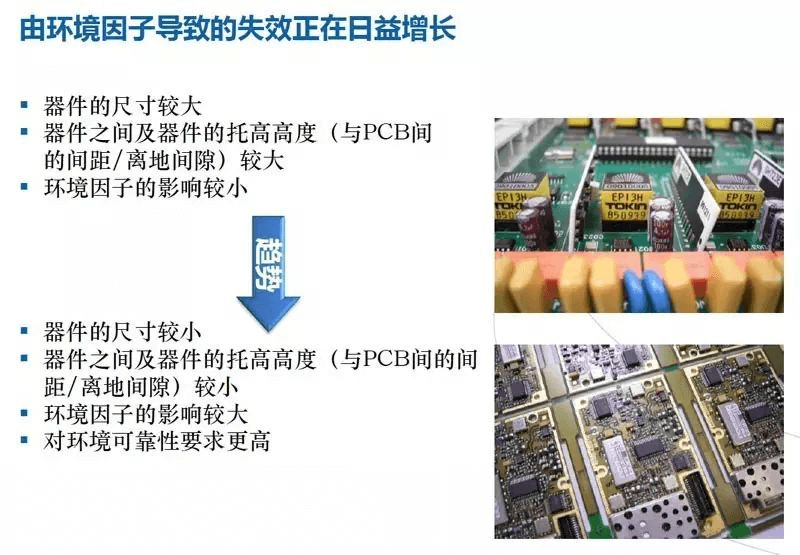

Njengoba ubukhulu bezingxenye ze-PCBA buba buncane futhi bube buncane, ukuminyana kuba phezulu nangaphezulu; Ukuphakama okusekelayo phakathi kwamadivayisi namadivayisi (isikhala phakathi kwe-PCB nokuvunyelwa phansi) nakho kuya ngokuya kuncipha, futhi nomthelela wezinto zemvelo ku-PCBA nawo uyakhula. Ngakho-ke, sibeka phambili izidingo eziphakeme ekuthembekeni kwe-PCBA yemikhiqizo kagesi.

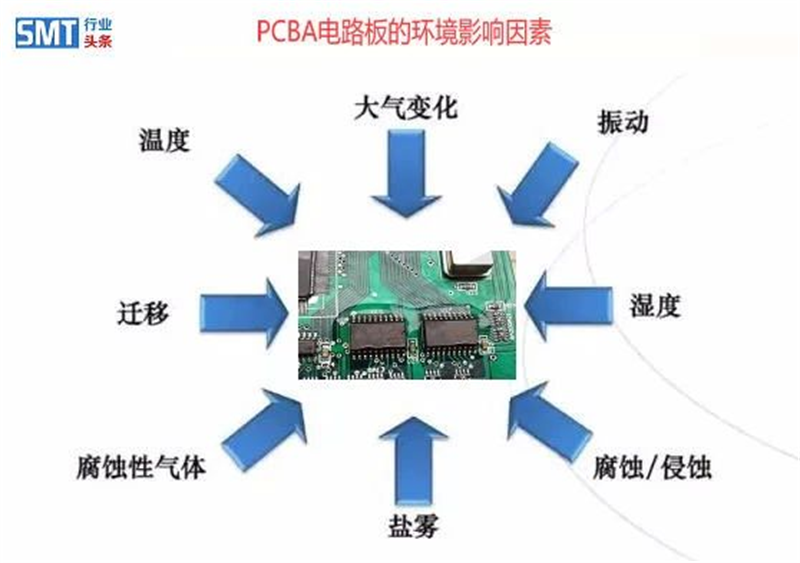

1. Izici zemvelo kanye nomthelela wazo

Izinto ezivamile zemvelo ezinjengomswakama, uthuli, isifutho sikasawoti, isikhunta, njll., zingadala izinkinga ezihlukahlukene zokuhluleka kwe-PCBA

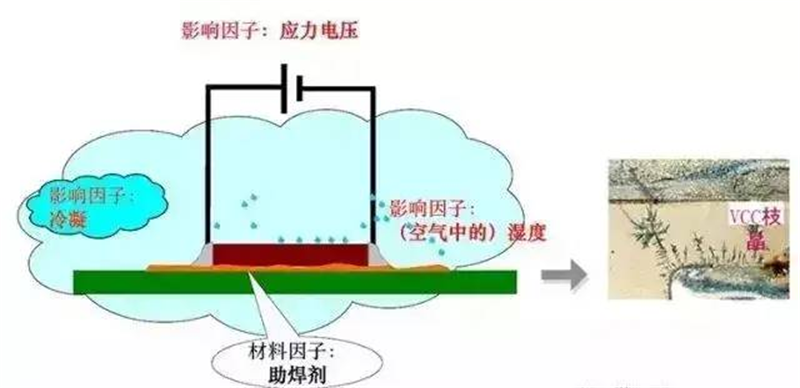

Umswakama

Cishe zonke izingxenye ze-PCB zikagesi endaweni yangaphandle zisengozini yokugqwala, phakathi kwazo amanzi ayindlela ebaluleke kakhulu yokugqwala. Ama-molecule amanzi mancane ngokwanele ukuthi angangena esikhaleni semolekyuli ye-mesh yezinye izinto ze-polymer futhi angene ngaphakathi noma afinyelele insimbi engaphansi ngembobo yokumboza ukuze abangele ukugqwala. Uma umkhathi ufinyelela umswakamo othile, ungabangela ukufuduka kwe-electrochemical PCB, ukuvuza kwamanje kanye nokuhlanekezela kwesignali kumjikelezo wefrikhwensi ephezulu.

Umhwamuko/umswakama + ukungcola kwe-ionic (usawoti, ama-flux asebenzayo) = ama-electrolyte asebenzayo + i-stress voltage = ukufuduka kwe-electrochemical

Lapho i-RH emkhathini ifinyelela ku-80%, kuzoba nefilimu yamanzi enogqinsi lwama-molecule angu-5 ~ 20, futhi zonke izinhlobo zama-molecule zingahamba ngokukhululeka. Uma i-carbon ikhona, ukusabela kwe-electrochemical kungenzeka.

Lapho i-RH ifinyelela ku-60%, ungqimba olungaphezulu lwemishini luzokwakha ama-molecule wamanzi angu-2 ~ 4 aminyene ifilimu, lapho kukhona ukungcola kuhlakazeka, kuzoba nokusabela kwamakhemikhali;

Lapho i-RH <20% emkhathini, cishe zonke izenzakalo zokubola ziyama.

Ngakho-ke, ubufakazi bomswakama buyingxenye ebalulekile yokuvikela umkhiqizo.

Ezisetshenziswa zikagesi, umswakama uza ngezindlela ezintathu: imvula, ukujiya kanye nomhwamuko wamanzi. Amanzi ayi-electrolyte encibilikisa inani elikhulu lama-ion agqwalayo agqwalisa izinsimbi. Lapho izinga lokushisa lengxenye ethile yezinto zokusebenza lingaphansi “kwephuzu lamazolo” (izinga lokushisa), kuzoba nokufingqa phezulu: izingxenye zesakhiwo noma i-PCBA.

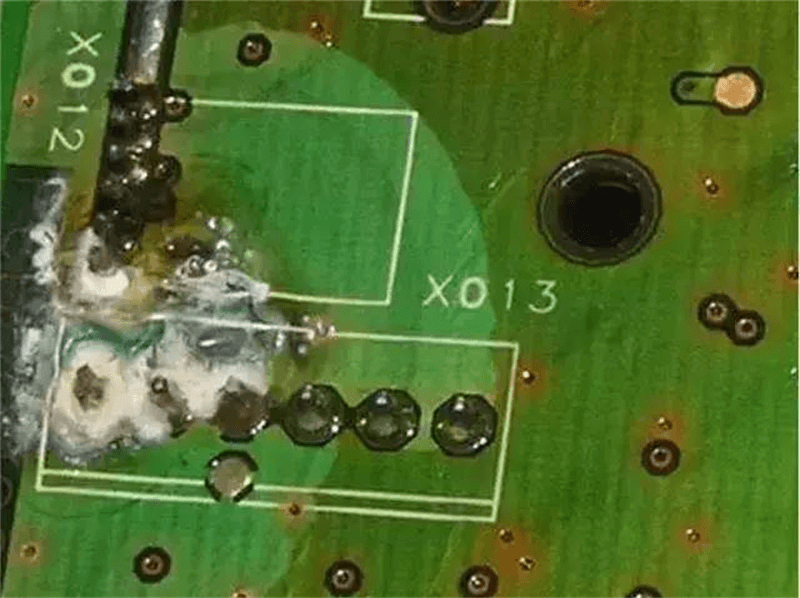

Uthuli

Kukhona uthuli emkhathini, ukungcola kwe-ion adsorbed kuhlala ngaphakathi kwemishini kagesi futhi kubangele ukwehluleka. Lena inkinga evamile ngokwehluleka kwe-elekthronikhi emkhakheni.

Uthuli luhlukene kabili: uthuli olumahhadla ububanzi bama-microns angu-2.5~15 wezinhlayiya ezingajwayelekile, ngokuvamile ngeke lubangele iphutha, i-arc nezinye izinkinga, kodwa luthinte othintana naye wesixhumi; Uthuli oluhle yizinhlayiya ezingajwayelekile ezinobubanzi obungaphansi kwama-microns angu-2.5. Uthuli oluhle lunokunamathela okuthile ku-PCBA (veneer), engasuswa kuphela ngebhulashi eliphikisayo.

Izingozi zothuli:a. Ngenxa yothuli oluhlala phezu kwe-PCBA, ukugqwala kwe-electrochemical kukhiqizwa, futhi izinga lokuhluleka liyakhula; b. Uthuli + ukushisa okuswakeme + inkungu kasawoti yabangela umonakalo omkhulu ku-PCBA, futhi ukwehluleka kwemishini kagesi kwaba kakhulu embonini yamakhemikhali nendawo yezimayini eduze nogu, ugwadule (umhlaba we-saline-alkali) naseningizimu yoMfula i-Huaihe phakathi nenkathi yokukhunta nemvula.

Ngakho-ke, ukuvikela uthuli kuyingxenye ebalulekile yomkhiqizo.

Isifutho sikasawoti

Ukwakhiwa kwe-salt spray:Isifutho sikasawoti sibangelwa izici zemvelo ezifana namagagasi olwandle, amagagasi, ukujikeleza komkhathi (monsoon) ukucindezela, ukukhanya kwelanga nokunye. Izokhukhuleka phakathi nezwe nomoya, futhi ukugxila kwayo kuzokwehla ngebanga ukusuka ogwini. Imvamisa, ukugcwala kwesifutho sikasawoti ku-1% wogu uma kuyi-1Km ukusuka ogwini (kodwa kuzophephezela kude ngesikhathi sezishingishane).

Ubungozi be-salt spray:a. limaza ukumbozwa kwezingxenye zesakhiwo sensimbi; b. Ukusheshisa kwejubane lokugqwala kwe-electrochemical kuholela ekuqhekekeni kwezintambo zensimbi kanye nokwehluleka kwezingxenye.

Imithombo efanayo yokugqwala:a. Umjuluko wesandla uqukethe usawoti, i-urea, i-lactic acid namanye amakhemikhali, anomthelela ofanayo wokugqwala ezintweni zikagesi njengesifutho sikasawoti. Ngakho-ke, amagilavu kufanele agqoke ngesikhathi sokuhlangana noma ukusetshenziswa, futhi ukumboza akufanele kuthinteke ngezandla ezingenalutho; b. Kukhona ama-halogens nama-acids ku-flux, okufanele ahlanzwe futhi ukugxila kwawo okusele kulawulwe.

Ngakho-ke, ukuvimbela isifutho sikasawoti kuyingxenye ebalulekile yokuvikelwa kwemikhiqizo.

Isikhunta

Isikhutha, igama elivamile lesikhunta esinama-filamentous, lisho “isikhunta esikhuntile,” sivame ukwakha i-mycelium evundile, kodwa asikhiqizi imizimba emikhulu ethela izithelo njengamakhowe. Ezindaweni ezimanzi nezifudumele, izinto eziningi zikhula ngeso lenyama ezinye zezindawo ezimise okwentambo ye-cobweb, okuyisikhunta.

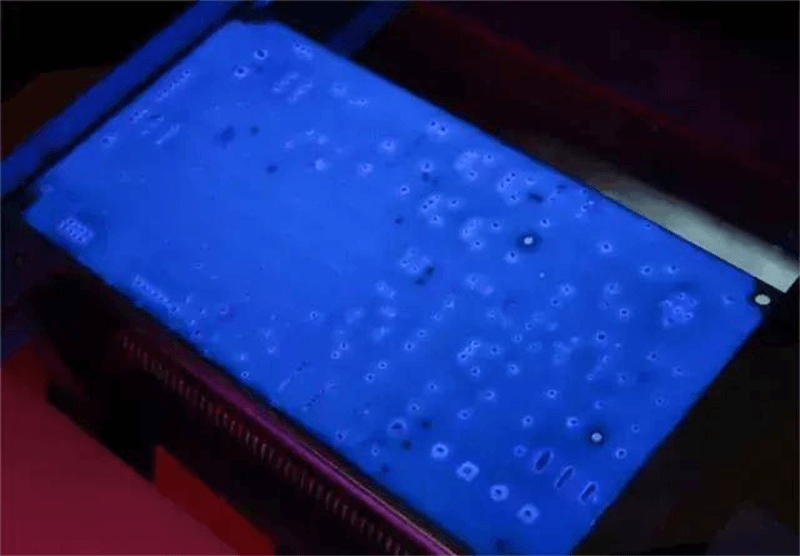

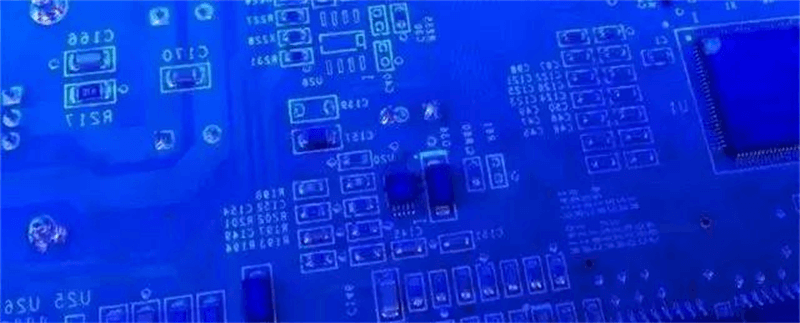

I-FIG. 5: PCB isikhutha

Ukulimala kwesikhunta:a. isikhunta i-phagocytosis kanye nokusakazeka kwenza ukufakwa kwezinto eziphilayo kunciphe, ukulimala nokwehluleka; b. Ama-metabolites esikhunta angama-asidi e-organic, athinta ukufakwa kanye namandla kagesi futhi akhiqize i-arc kagesi.

Ngakho-ke, i-anti-mold iyingxenye ebalulekile yemikhiqizo yokuvikela.

Ngokucabangela izici ezingenhla, ukwethembeka komkhiqizo kufanele kuqinisekiswe kangcono, kufanele kuhlukaniswe nemvelo yangaphandle ngendlela ephansi ngangokunokwenzeka, ngakho-ke inqubo yokumboza ukuma kwethulwa.

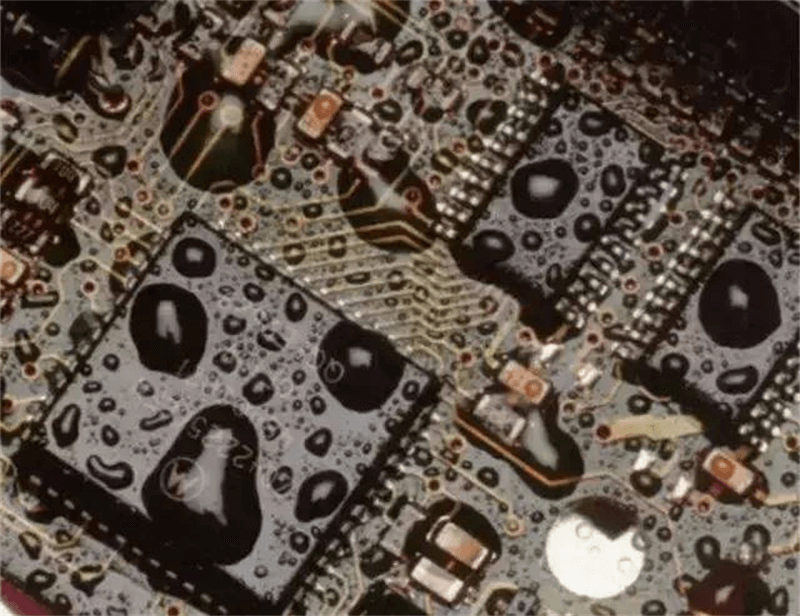

I-Coating PCB ngemuva kwenqubo yokuhlanganisa, ngaphansi komphumela wokudubula kwesibani esinsomi, ukunamathela kwangempela kungaba kuhle kakhulu!

Izembatho ezintathu zokulwa nopendeisho ukumboza ungqimba oluncane oluvikelayo oluvikelayo ebusweni be-PCB. Kuyindlela evame ukusetshenziswa kakhulu ye-post-welding coating okwamanje, ngezinye izikhathi ebizwa ngokuthi i-surface coating kanye ne-conformal coating (igama lesiNgisi: i-coating, i-conformal coating). Izohlukanisa izingxenye ze-elekthronikhi ezibucayi endaweni enzima, ingathuthukisa kakhulu ukuphepha nokuthembeka kwemikhiqizo ye-elekthronikhi futhi yandise impilo yesevisi yemikhiqizo. Izingubo ezintathu zokulwa nopende zingavikela isekethe/izingxenye ezicini zemvelo ezinjengomswakama, ukungcola, ukugqwala, ingcindezi, ukushaqeka, ukudlidliza komshini kanye nomjikelezo wokushisa, kuyilapho kuthuthukisa amandla emishini nezici zokushisa zomkhiqizo.

Ngemuva kwenqubo yokumboza ye-PCB, yakha ifilimu evikelayo ebonakalayo ebusweni, ingavimbela ngokuphumelelayo ukungena kwamanzi nomswakama, ugweme ukuvuza nokujikeleza okufushane.

2. Amaphuzu ayinhloko wenqubo yokugqoka

Ngokwezidingo ze-IPC-A-610E(Electronic Assembly Testing Standard), ibonakala kakhulu kulezi zici ezilandelayo:

Isifunda

1. Izindawo ezingakwazi ukumbozwa:

Izindawo ezidinga ukuxhunywa kukagesi, njengamaphedi egolide, iminwe yegolide, insimbi ephuma emigodini, izimbobo zokuhlola;

Amabhethri nezilungisi zebhethri;

Isixhumi;

I-Fuse ne-casing;

Idivayisi yokukhipha ukushisa;

I-Jumper wire;

I-lens yedivayisi ye-optical;

I-Potentiometer;

Inzwa;

Ayikho inkinobho evaliwe;

Ezinye izindawo lapho ukugqoka kungathinta ukusebenza noma ukusebenza.

2. Izindawo okumele zimbozwe: wonke amalunga e-solder, izikhonkwane, izingxenye kanye nama-conductor.

3. Izindawo ozikhethela zona

Ubukhulu

Ubukhulu bulinganiswa endaweni eyisicaba, engavinjelwe, eselashiwe yengxenye yesekethe ephrintiwe noma epuletini elinamathiselwe elenza inqubo nengxenye. Amabhodi anamathiselwe angase abe yimpahla efanayo namabhodi aphrintiwe noma ezinye izinto ezingezona izimbotshana, njengensimbi noma ingilazi. Isilinganiso sobukhulu befilimu emanzi singasetshenziswa futhi njengendlela yokuzikhethela yokulinganisa ukujiya kokumboza, inqobo nje uma kunobudlelwano bokuguqulwa obubhaliwe phakathi kogqinsi lwefilimu emanzi nokomile.

Ithebula 1: Izinga lobubanzi bokuqina bohlobo ngalunye lwempahla yokunameka

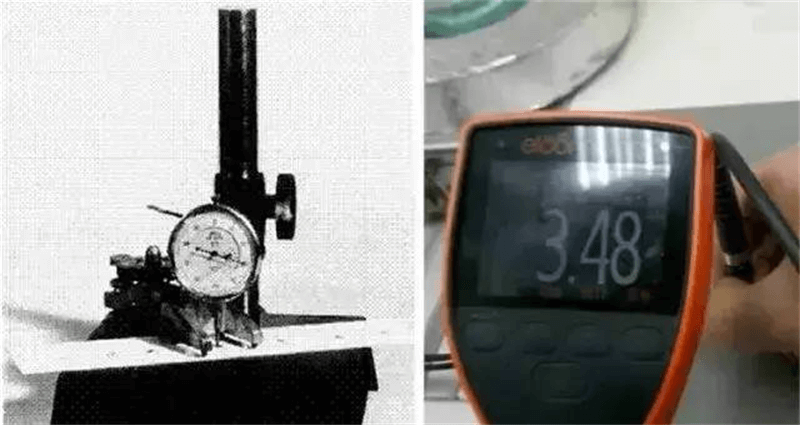

Indlela yokuhlola ukujiya:

1.Ithuluzi lokulinganisa ukujiya kwefilimu elomile: i-micrometer (IPC-CC-830B); b Umhloli wokuqina kwefilimu eyomile (isisekelo sensimbi)

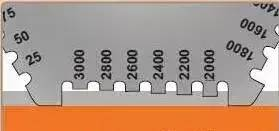

Umfanekiso 9. Imishini yefilimu eyomile ye-Micrometer

2. Isilinganiso sokuqina kwefilimu emanzi: ubukhulu befilimu emanzi bungatholwa ngensimbi yokulinganisa ukushuba kwefilimu emanzi, bese kubalwa ngengxenye yokuqukethwe okuqinile kweglue.

Ubukhulu befilimu eyomile

Ku-FIG. 10, ubukhulu befilimu obumanzi butholwe umhloli wefilimu omanzi, bese kubalwa ubukhulu befilimu eyomile.

Ukulungiswa komphetho

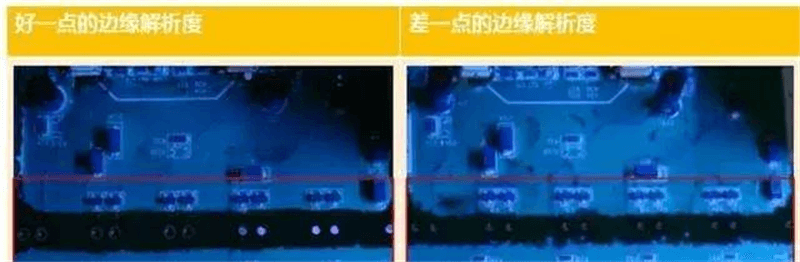

Incazelo: Ngaphansi kwezimo ezijwayelekile, isifutho se-valve yesifutho ngaphandle konqenqema lomugqa ngeke siqonde kakhulu, kuzohlala kukhona i-burr ethile. Sichaza ububanzi be-burr njengokulungiswa komphetho. Njengoba kukhonjisiwe ngezansi, usayizi we-d uyinani lokulungiswa komphetho.

Qaphela: Ukulungiswa konqenqema ngokuqinisekile kuncane kakhulu, kodwa izidingo zekhasimende ezihlukile azifani, ngakho-ke ukulungiswa konqenqema okunamathiselwe okuthile inqobo nje uma kuhlangabezana nezidingo zekhasimende.

Umfanekiso 11: Ukuqhathaniswa kokulungiswa komphetho

Ukufana

I-Glue kufanele ibe njengobukhulu obufanayo kanye nefilimu ebushelelezi futhi esobala ehlanganiswe emkhiqizweni, kugcizelelwa ukufana kweglue embozwe umkhiqizo ngaphezu kwendawo, ngakho-ke, kufanele kube ubukhulu obufanayo, azikho izinkinga zenqubo: ukuqhekeka, ukuhlukaniswa, imigqa yewolintshi, ukungcola, i-capillary phenomenon, ama-bubbles.

Umfanekiso 12: Umphumela we-Axial othomathikhi we-AC othomathikhi wokuhlanganisa umshini wokuhlanganisa, ukufana kuyahambisana kakhulu

3. Ukugcwaliseka kwenqubo yokumboza

Inqubo yokumboza

1 Lungiselela

Lungiselela imikhiqizo kanye ne-glue nezinye izinto ezidingekayo;

Ukunquma indawo yokuvikelwa kwendawo;

Nquma imininingwane ebalulekile yenqubo

2: Geza

Kufanele kuhlanzwe ngesikhathi esifushane ngemva Welding, ukuvimbela Welding ukungcola kunzima ukuhlanza;

Ukunquma ukuthi ukungcola okuyinhloko kuyi-polar, noma okungeyona i-polar, ukuze ukhethe i-ejenti yokuhlanza efanele;

Uma kusetshenziswa i-ejenti yokuhlanza utshwala, izindaba zokuphepha kufanele zinakwe: kufanele kube nemithetho yenqubo yokupholisa umoya kanye nokupholisa nokomisa ngemva kokugeza, ukuvimbela ukuvuthwa kwe-solvent okusele okubangelwa ukuqhuma kuhhavini;

Ukuhlanza amanzi, nge-alkaline yokuhlanza uketshezi (emulsion) ukugeza i-flux, bese uhlanza ngamanzi ahlanzekile ukuhlanza uketshezi lokuhlanza, ukuhlangabezana nezindinganiso zokuhlanza;

3. Isivikelo sokufihla ubuso (uma kungekho mishini yokumboza ekhethiwe), okungukuthi, imaski;

Kufanele ukhethe ifilimu non-adhesive ngeke ukudlulisa tape iphepha;

I-Anti-static paper tape kufanele isetshenziselwe ukuvikela i-IC;

Ngokwezidingo zemidwebo yamanye amadivaysi ukuvikela ukuvikelwa;

4. Susa umswakama

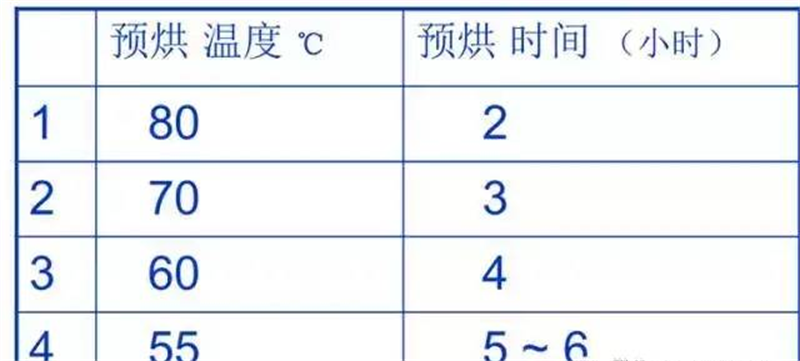

Ngemuva kokuhlanza, i-PCBA evikelekile (ingxenye) kumele yomiswe ngaphambili futhi ikhishwe emanzini ngaphambi kokumbozwa;

Nquma izinga lokushisa/isikhathi sokumisa ngaphambilini ngokwezinga lokushisa elivunyelwe yi-PCBA (ingxenye);

I-PCBA (ingxenye) ingavunyelwa ukucacisa izinga lokushisa/isikhathi sethebula lokomisa ngaphambili

5 Ijazi

Inqubo yokumboza umumo incike ezidingweni zokuvikela ze-PCBA, imishini yenqubo ekhona kanye nendawo ekhona yobuchwepheshe, evame ukufezwa ngalezi zindlela ezilandelayo:

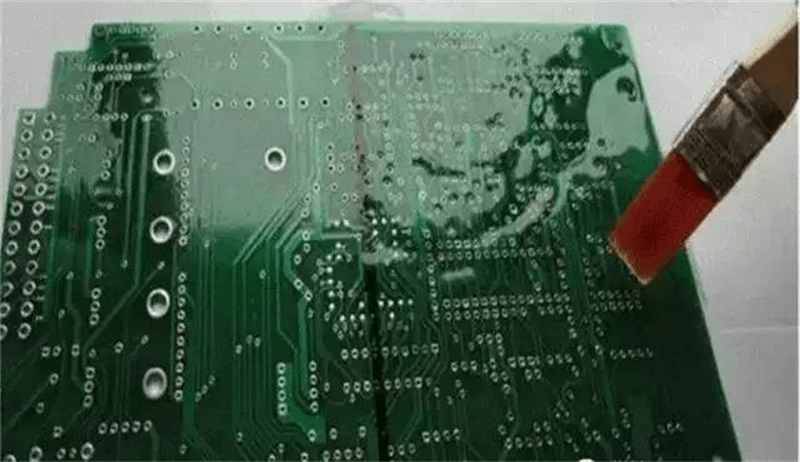

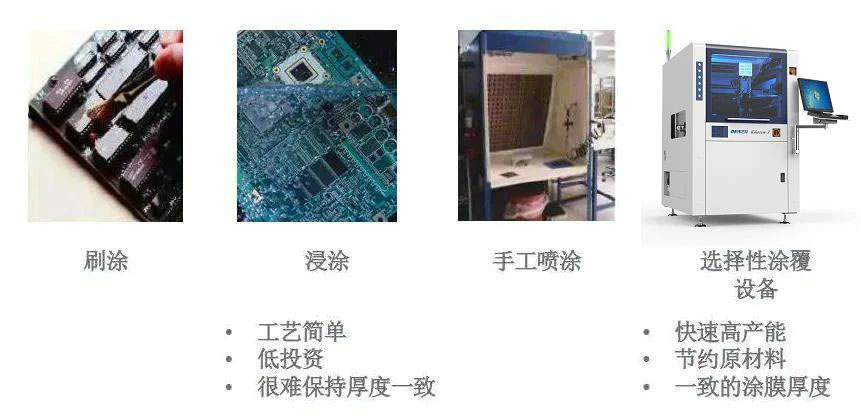

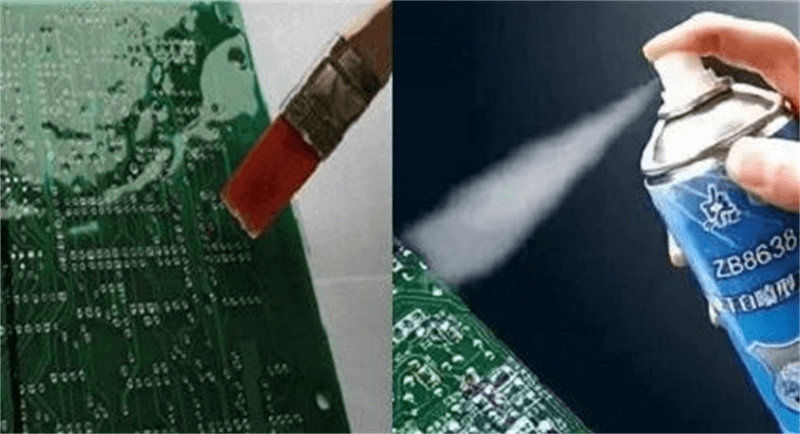

a. Gcoba ngesandla

Umfanekiso 13: Indlela yokuxubha ngesandla

Ukugcotshwa kwebhulashi kuyinqubo esetshenziswa kabanzi, elungele ukukhiqizwa kwenqwaba encane, isakhiwo se-PCBA esiyinkimbinkimbi futhi esiminyene, sidinga ukuvikela izidingo zokuvikela zemikhiqizo enokhahlo. Ngoba ukugqoka kwebhulashi kungalawulwa ngokukhululekile, ukuze izingxenye ezingavunyelwe ukudweba ngeke zingcoliswe;

Ukugqoka ibhulashi kudla okuncane kakhulu, okufanelekile ngentengo ephakeme yopende wezingxenye ezimbili;

Inqubo yokudweba inezidingo eziphezulu ku-opharetha. Ngaphambi kokwakhiwa, imidwebo kanye nezidingo zokumboza kufanele kugaywe ngokucophelela, amagama ezingxenye ze-PCBA kufanele aqashelwe, futhi izingxenye ezingavunyelwe ukugcotshwa kufanele zimakwe ngezimpawu ezidonsa amehlo;

Ama-opharetha awavunyelwe ukuthinta i-plug-in ephrintiwe ngezandla noma kunini ukugwema ukungcola;

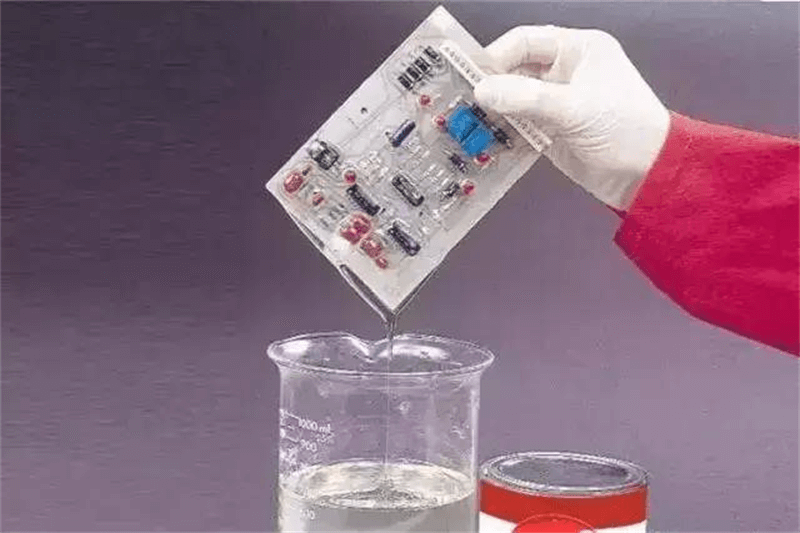

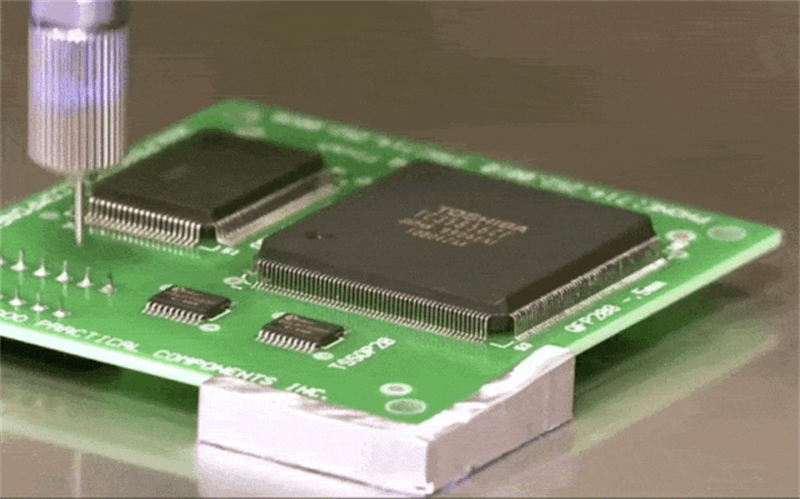

b. Gcoba ngesandla

Umfanekiso 14: Indlela yokuhlanganisa idiphu ngesandla

Inqubo yokugcoba i-dip inikeza imiphumela engcono kakhulu yokugqoka. Umfaniswano, ukunamathela okuqhubekayo kungasetshenziswa kunoma iyiphi ingxenye ye-PCBA. Inqubo yokumboza idiphu ayiwafanele ama-PCba anama-capacitor alungisekayo, ama-cores kazibuthe alungisa kahle, ama-potentiometer, ama-cores kazibuthe amise okwenkomishi nezinye izingxenye ezinokuvaleka kahle.

Imingcele ebalulekile yenqubo yokuhlanganisa idiphu:

Lungisa i-viscosity efanele;

Lawula isivinini i-PCBA ephakanyiswa ngaso ukuvimbela amabhamuza ukuthi akheke. Ngokuvamile akukho ngaphezu kwemitha elingu-1 ngomzuzwana;

c. Ukufafaza

Ukufafaza iyona esetshenziswa kabanzi, kulula ukwamukela indlela yenqubo, ihlukaniswe izigaba ezimbili ezilandelayo:

① Ukufafaza ngesandla

Umfanekiso 15: Indlela yokufafaza mathupha

Efanelekayo workpiece kuyinkimbinkimbi kakhudlwana, kunzima ukuthembela imishini ezishintshayo isimo sokukhiqiza mass, futhi efanelekayo umugqa umkhiqizo ezihlukahlukene kodwa isimo kancane, kungenziwa olufuthwe endaweni ekhethekile.

Inothi lokufafaza mathupha: inkungu kapende izongcolisa amanye amadivaysi, njenge-PCB plug-in, isokhethi ye-IC, abanye abathintwayo abazwelayo nezinye izingxenye eziphansi, lezi zingxenye zidinga ukunaka ukuthembeka kokuvikelwa kwendawo yokukhosela. Elinye iphuzu ukuthi opharetha akufanele athinte ipulaki ephrintiwe ngesandla sakhe nganoma yisiphi isikhathi ukuvimbela ukungcoliswa kwendawo yokuxhumana yepulaki.

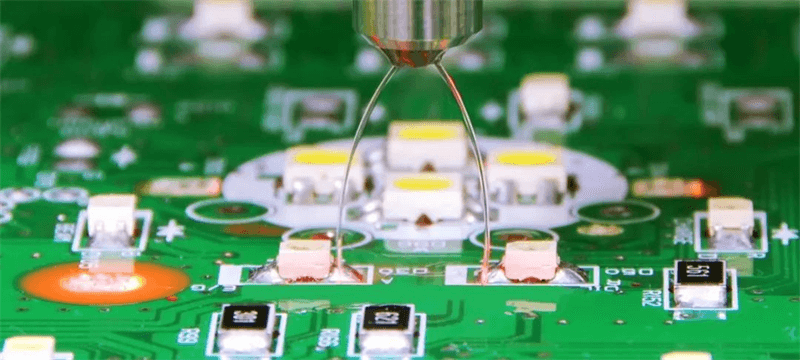

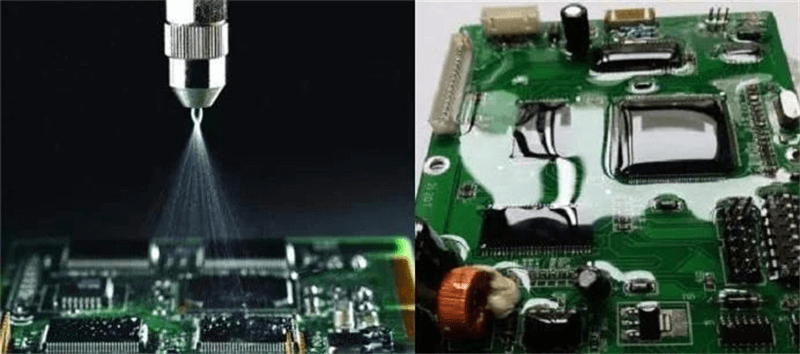

② Ukufafaza okuzenzakalelayo

Ngokuvamile kubhekisela ekufutheni okuzenzakalelayo ngemishini yokuhlanganisa ekhethiwe. Ifanele ukukhiqizwa ngobuningi, ukungaguquguquki okuhle, ukunemba okuphezulu, ukungcoliswa kwemvelo okuncane. Ngokuthuthukiswa kwezimboni, ukwanda kwezindleko zabasebenzi kanye nezidingo eziqinile zokuvikelwa kwemvelo, imishini yokufafaza ngokuzenzakalelayo ithatha indawo yezinye izindlela zokumboza.

Ngezidingo ezikhulayo zokuzenzakalela kwemboni 4.0, ukugxilwa kwemboni sekushintshile ekunikezeni izinto zokuhlanganisa ezifanele kuya ekuxazululeni inkinga yayo yonke inqubo yokuhlanganisa. Umshini wokugqoka okhethiwe ozenzakalelayo - ukumboza okunembile futhi akukho mfucumfucu wezinto ezibonakalayo, ofanele ubuningi bokugqoka, ofaneleka kakhulu ngamanani amakhulu we-anti-paint coating.

Ukuqhathaniswa kweothomathikhi enamathela umshinifuthiinqubo enamathela bendabuko

I-PCBA yendabuko yokuhlanganisa ngopende enobufakazi obuthathu:

1) Ibhulashi enamathela: kukhona Bubbles, amagagasi, shayela izinwele ukususwa;

2) Ukubhala: kancane kakhulu, ukunemba akukwazi ukulawulwa;

3) Ukucwilisa ucezu lonke: upende omosha kakhulu, ijubane eliphansi;

4) Fafaza isibhamu: ukuvikela indawo, khukhuleka kakhulu

Umshini wokugcwalisa uwoyela:

I-1) Inani lomdwebo wesifutho, isikhundla sokudweba isifutho kanye nendawo isethwe ngokunembile, futhi asikho isidingo sokwengeza abantu ukuze basule ibhodi ngemva kokudweba kwesifutho.

2) Ezinye izingxenye ze-plug-in ezinezikhala ezinkulu ukusuka onqenqemeni lwepuleti zingapendwa ngokuqondile ngaphandle kokufaka into ethile, konga abasebenzi bokufaka amapuleti.

I-3) Akukho ukuguquguquka kwegesi, ukuqinisekisa indawo yokusebenza ehlanzekile.

I-4) Yonke i-substrate ayidingi ukusebenzisa izinto zokulungisa ukumboza ifilimu ye-carbon, ukuqeda amathuba okushayisana.

5) Umfaniswano wokujiya kapende wokulwa nopende, uthuthukisa kakhulu ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo, kodwa futhi ugweme imfucuza kapende.

I-PCBA othomathikhi emithathu yomshini wokuhlanganisa upende, yakhelwe ngokukhethekile ukufafaza imishini emithathu ehlakaniphile yokufafaza kapende. Ngenxa yokuthi izinto okufanele zifuthwe kanye noketshezi olufafazayo luhlukile, umshini wokuhlanganisa ekwakhiweni kokukhethwa kwengxenye yemishini nawo uhlukile, umshini wokugcwalisa upende we-anti-paint wamukela uhlelo lwakamuva lokulawula ikhompyutha, ungabona ukuxhumana kwe-axis emithathu, ngesikhathi esifanayo ifakwe ikhamera yokumisa nokulandela umkhondo, ingakwazi ukulawula ngokunembile indawo yokufafaza.

Imishini emithathu yokuhlanganisa i-anti-peyinti, eyaziwa nangokuthi umshini weglue omelene nopende, umshini wokunamathisela weglue wokunqanda upende, umshini wesithathu wokufafaza uwoyela wokunqanda upende, umshini wokufafaza ophikisana nopende, ungowokulawula uketshezi, endaweni ye-PCB embozwe ungqimba lwama-anti-paint amathathu, njengokungena, ukufutha noma indlela yokuphotha endaweni ye-PCB embozwe ungqimba lwe-photoresist.

Indlela yokuxazulula inkathi entsha yesidingo se-anti paint coating, sekuyinkinga ephuthumayo okufanele ixazululwe embonini. Imishini yokuhlanganisa ezenzakalelayo emelwe umshini wokuhlanganisa okhethayo uletha indlela entsha yokusebenza,enamathela olunembile futhi akukho ukumosha izinto, ofanele kakhulu inombolo enkulu enamathela ezintathu anti-pende.

Isikhathi sokuthumela: Jul-08-2023