Qonda i-DIP

I-DIP iyi-plug-in. Ama-chips apakishwe ngale ndlela anemigqa emibili yezikhonkwane, ezingashiselwa ngokuqondile kumasokhethi e-chip anesakhiwo se-DIP noma ashiselwe ezindaweni zokushisela ezinenombolo efanayo yezimbobo. Kulula kakhulu ukuqaphela welding PCB ibhodi perforation, futhi ukuhambisana okuhle motherboard, kodwa ngenxa indawo yayo ukupakisha kanye ukushuba kukhulu uma kuqhathaniswa, futhi iphinikhodi inqubo ukufakwa kanye nokususwa kulula ukonakala, ukwethembeka okubi.

I-DIP iyiphakheji ye-plug-in ethandwa kakhulu, ububanzi bohlelo lokusebenza buhlanganisa i-logic evamile ye-IC, imemori ye-LSI, izifunda ze-microcomputer, njll. Iphakheji yephrofayela encane (SOP), etholakala ku-SOJ (i-J-type pin iphakheji elincane lephrofayela), i-TSOP (iphakheji elincane lephrofayela encane), i-VSOP (iphakheji elincane kakhulu lephrofayela), i-SSOP (i-SOP encishisiwe), i-TSSOP (iphrofayili encishisiwe ye-SOPmall ehlanganisiwe ye-SOPmall SOP) isifunda), njll.

Isici sokuklama komhlangano wedivayisi ye-DIP

Imbobo yephakheji ye-PCB inkulu kunedivayisi

Izimbobo ze-plug-in ze-PCB nezimbobo zamaphini wephakheji zidwetshwa ngokuhambisana nezicaciso. Ngenxa yesidingo se-copper Plating emigodini ngesikhathi sokwenziwa kwamapuleti, ukubekezelelana okuvamile kuhlanganisa noma kususe okungu-0.075mm. Uma imbobo yokupakisha ye-PCB inkulu kakhulu kunephinikhodi yedivayisi ephathekayo, kuzoholela ekuxegisweni kwedivayisi, ithini elinganele, i-air welding nezinye izinkinga zekhwalithi.

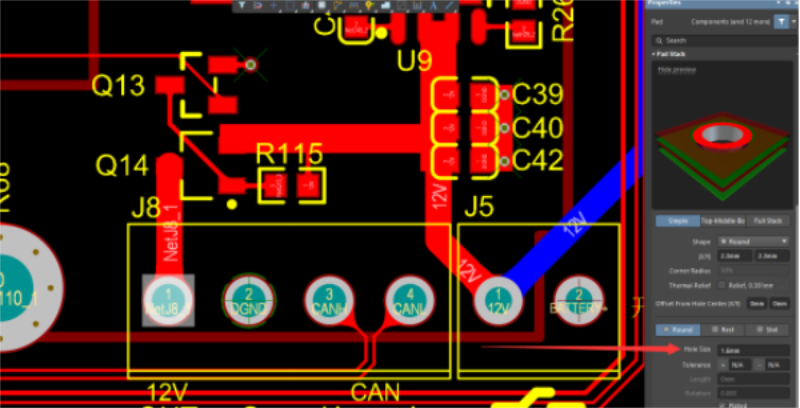

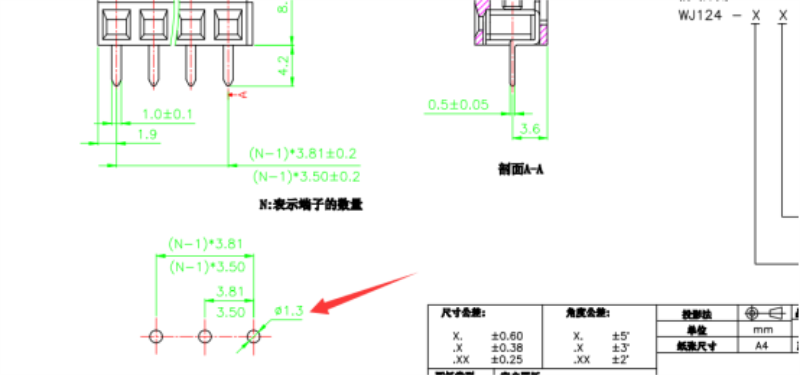

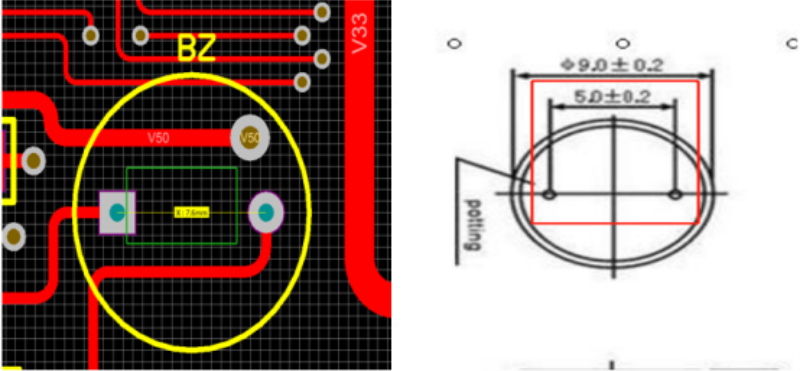

Bona isibalo esingezansi, usebenzisa i-WJ124-3.81-4P_WJ124-3.81-4P (KANGNEX) iphinikhodi yedivayisi ngu-1.3mm, imbobo yokupakisha ye-PCB ingu-1.6mm, indawo yokuvula inkulu kakhulu eholela ekushiseleni isikhathi sokushisela ngaphezu kwegagasi.

Okunamathiselwe esithombeni, thenga izingxenye ze-WJ124-3.81-4P_WJ124-3.81-4P (KANGNEX) ngokuya ngezidingo zokuklama, iphinikhodi engu-1.3mm ilungile.

Imbobo yephakheji ye-PCB incane kunedivayisi

I-Plug-in, kodwa ngeke imbobe ithusi, uma ingashadile futhi iphindwe kabili amaphaneli angasebenzisa le ndlela, amaphaneli angashadile nama-double angama-conductor angaphandle kagesi, i-solder ingaba conductive; Imbobo ye-plug-in yebhodi le-multilayer incane, futhi ibhodi le-PCB lingenziwa kabusha kuphela uma ungqimba lwangaphakathi lunokwenziwa kukagesi, ngoba ukuqhutshwa kwesendlalelo sangaphakathi akukwazi ukulungiswa ngokubuyisela kabusha.

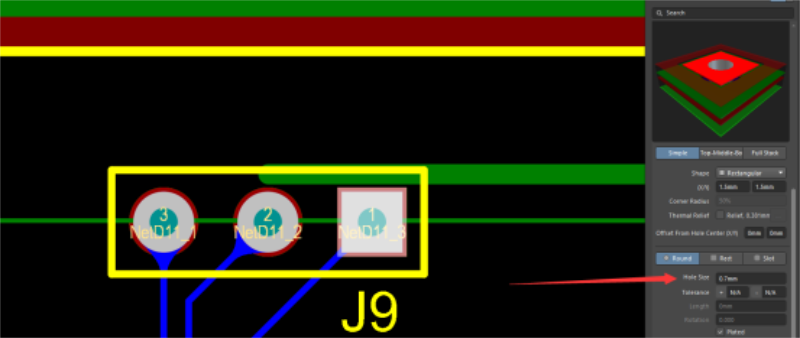

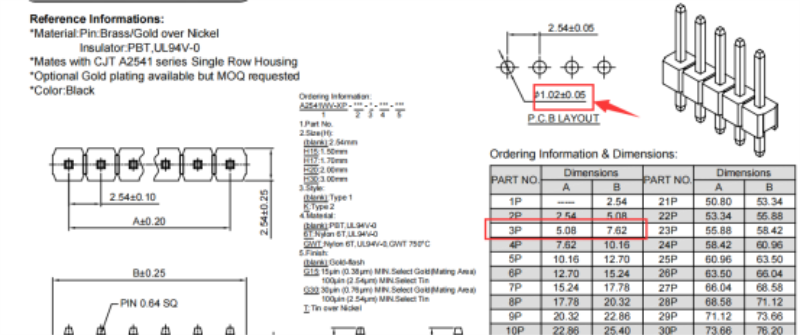

Njengoba kuboniswe emfanekisweni ongezansi, izingxenye ze-A2541Hwv-3P_A2541HWV-3P (CJT) zithengwa ngokuvumelana nezidingo zokuklama. Iphinikhodi ingu-1.0mm, futhi imbobo yephedi yokuvala ye-PCB ingu-0.7mm, okuholela ekuhlulekeni kokufaka.

Izingxenye ze-A2541Hwv-3P_A2541HWV-3P (CJT) zithengwa ngokwezidingo zokuklama. Iphinikhodi engu-1.0mm ilungile.

Isikhala sephinikhodi yephakheji siyahluka esikhaleni sedivayisi

Iphedi yokuvala ye-PCB yedivayisi ye-DIP ayigcini nje ngokuba nendawo yokuvula efanayo nephini, kodwa futhi idinga ibanga elifanayo phakathi kwezimbobo zokukhonkwane. Uma isikhala phakathi kwezimbobo zephini kanye nocingo singahambisani, idivayisi ayikwazi ukufakwa, ngaphandle kwezingxenye ezinezikhala ezilungisekayo zonyawo.

Njengoba kuboniswe emfanekisweni ongezansi, ibanga lembobo yephini lokupakishwa kwe-PCB lingu-7.6mm, futhi ibanga lembobo yephini lezinto ezithengiwe lingu-5.0mm. Umehluko ka-2.6mm uholela ekutheni idivayisi ingasebenziseki.

Izimbobo zokupakisha ze-PCB zisondele kakhulu

Ekwakhiweni kwe-PCB, ukudweba nokupakishwa, kuyadingeka ukuthi unake ibanga eliphakathi kwezimbobo zephini. Ngisho noma ipuleti elingenalutho lingakhiqizwa, ibanga phakathi kwezimbobo zephini lincane, kulula ukubangela ukujikeleza okufushane kwe-tin ngesikhathi somhlangano nge-wave soldering.

Njengoba kuboniswe esithombeni esingezansi, ukujikeleza okufushane kungase kubangelwe ibanga elincane lephini. Kunezizathu eziningi zokujikeleza okufushane ku-solder tin. Uma ukuhlangana kungavinjelwa kusengaphambili ekupheleni kokuklama, izehlakalo zezinkinga zingancishiswa.

Ikesi lenkinga yephinikhodi yedivayisi ye-DIP

Incazelo yenkinga

Ngemva kokushisela i-wave crest yomkhiqizo we-DIP, kwatholakala ukuthi kunokushoda okukhulu kwethayela epuleti le-solder lonyawo olungaguquki lwesokhethi yenethiwekhi, okungeye-air welding.

Umthelela wenkinga

Ngenxa yalokho, ukuzinza kwesokhethi yenethiwekhi kanye nebhodi le-PCB kuba kubi kakhulu, futhi amandla onyawo lwephinikhodi azosetshenziswa ngesikhathi sokusetshenziswa komkhiqizo, okuzogcina kuholele ekuxhumekeni kwephini lesignali, okuthinta ukusebenza komkhiqizo futhi kubangele ingozi yokwehluleka ekusetshenzisweni kwabasebenzisi.

Isandiso senkinga

Ukuzinza kwesokhethi yenethiwekhi akulungile, ukusebenza kokuxhuma kwephinikhodi kubi, kunezinkinga zekhwalithi, ngakho-ke kungase kulethe izingozi zokuphepha kumsebenzisi, ukulahlekelwa kokugcina akucabangeki.

Ukuhlolwa kokuhlaziywa kokuhlanganiswa kwedivayisi ye-DIP

Kunezinkinga eziningi ezihlobene nezikhonkwane zedivayisi ye-DIP, futhi amaphuzu amaningi abalulekile alula ukunganakwa, okuholela ebhodini lokugcina le-scrap. Ngakho kanjani ukuxazulula ngokushesha futhi ngokuphelele izinkinga ezinjalo unomphela?

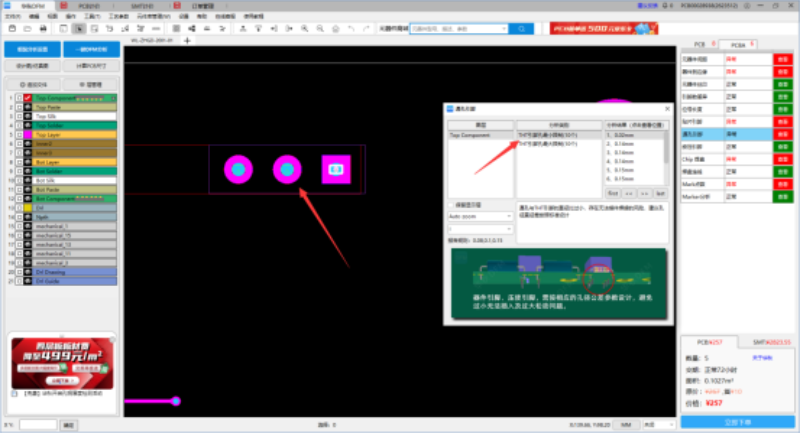

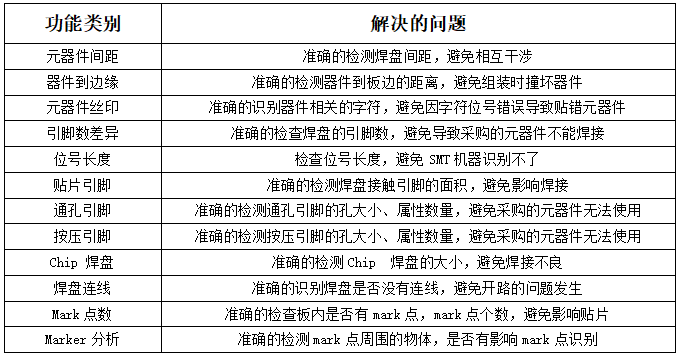

Lapha, umsebenzi wokuhlanganisa nokuhlaziya wesofthiwe yethu ye-CHIPSTOCK.TOP ungasetshenziswa ukwenza ukuhlolwa okukhethekile ezikhonkwane zemishini ye-DIP. Izinto zokuhlola zihlanganisa inani lezikhonkwane ngokusebenzisa izimbobo, umkhawulo omkhulu wezikhonkwane ze-THT, umkhawulo omncane wamaphini we-THT kanye nezici zamaphini we-THT. Izinto zokuhlola zamaphini ngokuyisisekelo zihlanganisa izinkinga ezingaba khona ekwakhiweni kwamadivaysi e-DIP.

Ngemva kokuphothulwa komklamo we-PCB, umsebenzi wokuhlaziya umhlangano we-PCBA ungasetshenziswa ukuthola amaphutha edizayini kusenesikhathi, ukuxazulula izinkinga zedizayini ngaphambi kokukhiqiza, futhi ugweme izinkinga zokuklama ohlelweni lokuhlanganisa, ukubambezeleka kwesikhathi sokukhiqiza kanye nokumosha ucwaningo nezindleko zokuthuthukisa.

Umsebenzi wayo wokuhlaziya umhlangano unezinto ezinkulu eziyi-10 kanye nemithetho yokuhlola izinto ezinhle ezingama-234, ehlanganisa zonke izinkinga ezingaba khona zokuhlanganisa, njengokuhlaziywa kwedivayisi, ukuhlaziya iphinikhodi, ukuhlaziywa kwephedi, njll., okungaxazulula izimo ezihlukahlukene zokukhiqiza onjiniyela abangenakuzilindela kusengaphambili.

Isikhathi sokuthumela: Jul-05-2023