【 Izimpahla ezomile 】 Ukuhlaziywa okujulile kwe-SMT kungani kufanele usebenzise ingcina ebomvu? (2023 Essence Edition), ukufanele!

I-SMT adhesive, eyaziwa nangokuthi i-SMT adhesive, i-SMT ebomvu enamathelayo, ngokuvamile ibomvu (nayo ephuzi noma emhlophe) ukunamathisela okusatshalaliswa ngokulinganayo nge-hardener, i-pigment, i-solvent nezinye izinto zokunamathela, ezisetshenziselwa kakhulu ukulungisa izingxenye ebhodini lokuphrinta, ngokuvamile elisakazwa ngokukhipha noma izindlela zokuphrinta isikrini sensimbi. Ngemva kokunamathisela izingxenye, zibeke kuhhavini noma kuhhavini lokuhambisa kabusha ukuze ufudumale futhi uqine. Umehluko phakathi kwayo kanye ne-solder paste yukuthi yelashwa ngemva kokushisa, izinga lokushisa layo lokuqandisa liyi-150 ° C, futhi ngeke lihlakazeke ngemva kokushisa kabusha, okusho ukuthi, inqubo yokuqina kokushisa kwe-patch ayinakuguqulwa. Umphumela wokusetshenziswa kokunamathela kwe-SMT uzohluka ngenxa yezimo zokuphulukisa ezishisayo, into exhunyiwe, okokusebenza okusetshenzisiwe, kanye nendawo yokusebenza. I-adhesive kufanele ikhethwe ngokuvumelana nenqubo yebhodi lesifunda ephrintiwe (PCBA, PCA).

Izici, ukusetshenziswa kanye nethuba lokunamathela kwe-SMT patch

Iglue ebomvu ye-SMT iwuhlobo lwenhlanganisela ye-polymer, izakhi eziyinhloko yizinto eziyisisekelo (okungukuthi, izinto eziyinhloko zamangqamuzana aphezulu), isigcwalisi, i-ejenti yokwelapha, ezinye izithasiselo nokunye. Iglue ebomvu ye-SMT ine-viscosity fluidity, izici zokushisa, izici zokumanzisa nokunye. Ngokwalesi sici se-glue ebomvu, ekukhiqizeni, inhloso yokusebenzisa i-glue ebomvu iwukuba izingxenye zinamathele ngokuqinile ebusweni be-PCB ukuze zingawi. Ngakho-ke, i-patch adhesive iwukusetshenziswa okumsulwa kwemikhiqizo yenqubo engabalulekile, futhi manje ngokuthuthuka okuqhubekayo komklamo nenqubo ye-PCA, ngokugeleza kabusha kwembobo kanye ne-double side-side reflow welding iye yabonakala, futhi inqubo yokufaka i-PCA esebenzisa i-adhesive patch ikhombisa umkhuba wokuncipha.

Inhloso yokusebenzisa okunamathelayo kwe-SMT

① Vimbela izingxenye ukuthi zingawi ekuhlanganisweni kwe-wave soldering (inqubo ye-wave soldering). Uma usebenzisa i-wave soldering, izingxenye zigxilwe ebhodini eliphrintiwe ukuvimbela izingxenye ukuthi zingawi lapho ibhodi eliphrintiwe lidlula emgodini we-solder.

② Vimbela olunye uhlangothi lwezingxenye ukuthi zingawi ku-reflow welding (inqubo ye-reflow welding ephindwe kabili). Enkambweni ye-welding ye-double-side reflow welding, ukuze kuvinjelwe amadivaysi amakhulu ohlangothini oludayisiwe ukuthi angawi ngenxa yokuncibilika kokushisa kwe-solder, i-SMT patch glue kufanele yenziwe.

③ Vimbela ukugudluzwa kanye nokuma kwezingxenye (inqubo ye-reflow welding, inqubo yokumboza ngaphambili). Isetshenziswa ezinqubweni zokushisela okugelezayo kanye nezinqubo zokumboza ngaphambili ukuvimbela ukufuduka kanye nokukhuphuka ngesikhathi sokukhuphuka.

④ Maka (i-wave soldering, i-reflow welding, i-pre-coating). Ngaphezu kwalokho, lapho amabhodi aphrintiwe kanye nezingxenye zishintshwa ngamaqoqo, i-patch adhesive isetshenziselwa ukumaka.

I-SMT adhesive ihlukaniswa ngokwendlela yokusetshenziswa

a) Uhlobo lokukhuhla: ukulinganisa kwenziwa ngemodi yokuphrinta kanye nokukhuhla yensimbi yensimbi. Le ndlela iyona esetshenziswa kakhulu futhi ingasetshenziswa ngokuqondile emshinini wokunamathisela we-solder. Izimbobo zensimbi kufanele zinqunywe ngokuya ngohlobo lwezingxenye, ukusebenza kwe-substrate, ubukhulu kanye nobukhulu kanye nokuma kwezimbobo. Izinzuzo zayo ijubane eliphezulu, ukusebenza kahle okuphezulu kanye nezindleko eziphansi.

b) Uhlobo lokukhipha: Iglue isetshenziswa ebhodini lesifunda eliphrintiwe ngokukhipha izinto zokusebenza. Imishini ekhethekile yokukhipha impahla iyadingeka, futhi izindleko ziphezulu. Imishini yokukhipha iwukusetshenziswa komoya ocindezelwe, iglue ebomvu ngokusebenzisa ikhanda elikhethekile lokukhipha ku-substrate, ubukhulu bephoyinti leglue, kungakanani, ngesikhathi, ububanzi beshubhu yokucindezela kanye neminye imingcele yokulawula, umshini wokukhipha unomsebenzi oguquguqukayo. Ezingxenyeni ezihlukene, singasebenzisa amakhanda ahlukene okusabalalisa, ukusetha imingcele ukuze ushintshe, ungashintsha futhi ukuma nobuningi bephoyinti leglue, ukuze ufeze umphumela, izinzuzo zilula, ziguquguqukayo futhi zizinzile. Ububi bulula ukuba nomdwebo wezintambo namabhamuza. Singalungisa amapharamitha wokusebenza, isivinini, isikhathi, umfutho womoya, nezinga lokushisa ukuze sinciphise lokhu kushiyeka.

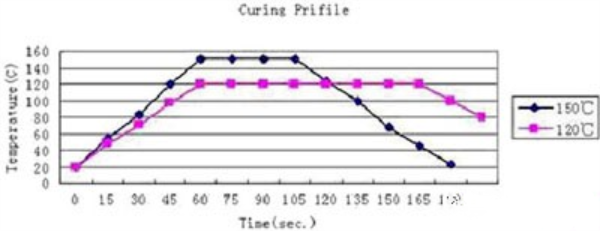

I-SMT patch adhesive izimo ezijwayelekile zokuphulukisa

| Ukwelapha izinga lokushisa | Isikhathi sokuphumula |

| 100 ℃ | 5 amaminithi |

| 120℃ | 150 imizuzwana |

| 150 ℃ | 60 imizuzwana |

Qaphela:

1, ukuphakama kwezinga lokushisa lokuphulukisa kanye nesikhathi eside sokuphulukisa, kuqina amandla okubopha.

I-2, ngenxa yokuthi izinga lokushisa le-adhesive patch lizoshintsha ngobukhulu bezingxenye ze-substrate kanye nesimo sokunyuka, sincoma ukuthola izimo zokuqina ezifanele kakhulu.

Ukugcinwa kweziqephu ze-SMT

Ingagcinwa izinsuku ezingu-7 ekamelweni lokushisa, izinyanga ezingaphezu kwezingu-6 ngaphansi kuka-5 ° C, futhi izinsuku ezingaphezu kwezingu-30 ku-5 ~ 25 ° C.

Ukuphathwa kokunamathela kwe-SMT

Ngenxa yokuthi i-SMT patch glue ebomvu ithintwa izinga lokushisa nge-viscosity yayo, i-fluidity, ukumanzisa nezinye izici, ngakho-ke i-SMT patch glue ebomvu kufanele ibe nezimo ezithile zokusetshenziswa nokuphathwa okujwayelekile.

I-1) I-glue ebomvu kufanele ibe nenombolo ethile yokugeleza, ngokuya ngenani lokuphakelayo, usuku, uhlobo lwenombolo.

I-2) I-glue ebomvu kufanele igcinwe esiqandisini ngo-2 ~ 8 ° C ukuvimbela izici ukuthi zingathinteki ngenxa yezinguquko zokushisa.

I-3) I-glue ebomvu iyadingeka ukuthi ifudumale ekamelweni lokushisa amahora angu-4, ngokulandelana kokusetshenziswa kokuqala kokuqala.

I-4) Ngomsebenzi wokukhipha, i-glue ebomvu ye-hose kufanele ihlanjululwe, futhi i-glue ebomvu engazange isetshenziswe kufanele ibuyiselwe esiqandisini ukuze igcinwe, futhi i-glue endala ne-glue entsha ayikwazi ukuxutshwa.

5) Ukuze ugcwalise ngokunembile ifomu lerekhodi lokushisa lokubuyisela, ukubuyisela umuntu wezinga lokushisa kanye nesikhathi sokushisa sokubuyisela, umsebenzisi udinga ukuqinisekisa ukuqedwa kwezinga lokushisa lokubuyisela ngaphambi kokusetshenziswa. Ngokuvamile, iglue ebomvu ayikwazi ukusetshenziswa ephelelwe yisikhathi.

Izici zenqubo ye-SMT patch adhesive

Amandla okuxhuma: Okunamathelayo kwe-SMT kumele kube namandla okuxhumana aqinile, ngemva kokuqina, ngisho nasezingeni elincibilikayo le-solder alicwebi.

Ukumbozwa kwamachashazi: Okwamanje, indlela yokusabalalisa yamabhodi aphrintiwe ikakhulukazi ukumbozwa kwamachashazi, ngakho ingcina iyadingeka ukuthi ibe nalezi zakhiwo ezilandelayo:

① Ijwayela kuzinqubo zokukhweza ezahlukahlukene

Kulula ukusetha ukunikezwa kwengxenye ngayinye

③ Kulula ukuzivumelanisa nokushintsha izingxenye zengxenye

④ Inani eliqinile lokumboza ichashazi

Ivumelanisa nomshini wesivinini esikhulu: i-patch adhesive manje esetshenziswayo kufanele ihlangabezane nesivinini esikhulu somshini wokupakisha kanye nesivinini esikhulu somshini wokupakisha, ikakhulukazi, okungukuthi, ukumbozwa kwendawo enesivinini esikhulu ngaphandle komdwebo wocingo, futhi okungukuthi, ukukhweza ngesivinini esikhulu, ibhodi eliphrintiwe kunqubo yokudlulisela, i-adhesive ukuqinisekisa ukuthi izingxenye azinyakazi.

Umdwebo wocingo, ukugoqa: uma i-patch glue inamathela ku-pad, izingxenye azikwazi ukufeza uxhumano lukagesi nebhodi eliphrintiwe, ngakho-ke i-patch glue akumele ibe nomdwebo wocingo ngesikhathi sokugqoka, akukho ukuwa ngemva kokugqoka, ukuze ungangcolisi pad.

Ukwelapha okunokushisa okuphansi: Lapho ukwelapha, izingxenye ze-plug-in ezikwazi ukumelana nokushisa ezishiselwe nge-wave crest welding kufanele futhi zidlule esithandweni somlilo sokugeleza kabusha, ngakho izimo zokuqina kufanele zihlangabezane nezinga lokushisa eliphansi kanye nesikhathi esifushane.

Ukuzilungisa ngokwakho: Enqubweni ye-reflow welding kanye ne-pre-coating, i-patch glue iyaphulukiswa futhi ilungiswe ngaphambi kokuba i-solder incibilike, ngakho-ke izovimbela ingxenye ukuthi ingacwili ku-solder nokuzilungisa. Ukuphendula lokhu, abakhiqizi baye bahlakulela isiqephu sokuzilungisa.

Izinkinga ezivamile zokunamathela kwe-SMT, amaphutha nokuhlaziya

ukucindezelwa

Isidingo samandla we-thrust we-capacitor engu-0603 yi-1.0KG, ukumelana kungu-1.5KG, amandla okucindezela kwe-0805 capacitor yi-1.5KG, ukumelana kungu-2.0KG, okungakwazi ukufinyelela umgomo ongenhla, okubonisa ukuthi amandla awanele.

Ngokuvamile kubangelwa izizathu ezilandelayo:

1, inani leglue alanele.

2, i-colloid ayilapheki ngo-100%.

3, PCB board noma izingxenye zingcolile.

I-4, i-colloid ngokwayo i-brittle, ayikho amandla.

ukungazinzi Thixotropic

Iglue yesirinji engu-30ml idinga ukushaywa amashumi ezinkulungwane zezikhathi ngomfutho womoya ukuze isetshenziswe, ngakho-ke iglue ye-patch ngokwayo iyadingeka ukuze ibe ne-thixotropy enhle kakhulu, ngaphandle kwalokho izodala ukungazinzi kwephoyinti le-glue, ingcina encane kakhulu, okuzoholela emandleni anganele, okubangela ukuba izakhi ziwe ngesikhathi sokusongeshwa kwamagagasi, ngokuphambene nalokho, inani leglue likhulu kakhulu, ukunamathisela okuncane kakhulu, ukunamathela kugesi kuncane, ikakhulukazi ukunamathela.

Iglue enganele noma indawo evuzayo

Izizathu Nezinyathelo Zokuphikisa:

1, ibhodi lokuphrinta alihlanzwa njalo, kufanele lihlanzwe nge-ethanol njalo emahoreni angu-8.

2, i-colloid inokungcola.

I-3, ukuvulwa kwebhodi le-mesh akunangqondo kuncane kakhulu noma ingcindezi yokukhipha incane kakhulu, ukwakheka kweglue enganele.

4, kukhona amagwebu ku-colloid.

5. Uma ikhanda elikhiphayo livinjiwe, umlomo wombhobho okhiphayo kufanele uhlanzwe ngokushesha.

6, izinga lokushisa langaphambi kokushisa kwekhanda elikhiphayo alanele, izinga lokushisa lekhanda elikhiphayo kufanele libekwe ku-38 ℃.

umdwebo wocingo

Okubizwa ngokuthi umdwebo wocingo kuyisimo sokuthi i-patch glue ayiphukile lapho isakazwa, futhi i-patch glue ixhunywe ngendlela ye-filamentous ekuqondeni kwekhanda elikhiphayo. Kukhona izintambo eziningi, futhi i-patch glue imbozwe ku-pad ephrintiwe, okuzobangela ukushisela okubi. Ikakhulukazi uma usayizi mkhulu, lesi simo cishe kungenzeka uma iphuzu enamathela umlomo. Umdwebo we-patch glue uthinteka kakhulu ngempahla yokudweba ye-resin yayo eyinhloko ye-resin kanye nokumiswa kwezimo zokugqoka amaphuzu.

1, khulisa i-stroke ekhiphayo, yehlise isivinini esinyakazayo, kodwa izokwehlisa isigqi sakho sokukhiqiza.

2, i-viscosity ephansi kakhulu, i-thixotropy ephezulu yezinto ezibonakalayo, ukuthambekela kokudweba kuncane, ngakho-ke zama ukukhetha i-patch adhesive.

I-3, izinga lokushisa le-thermostat liphakeme kancane, liphoqeleka ukuthi livumelane ne-viscosity ephansi, i-glue ephezulu ye-thixotropic patch, bese ucabangela isikhathi sokugcina se-patch glue kanye nokucindezela kwekhanda elikhiphayo.

umgodi

I-fluidity ye-patch izobangela ukugoqa. Inkinga evamile yokugoqa ukuthi ukubeka isikhathi eside kakhulu ngemuva kokumboza indawo kuzodala ukuwa. Uma i-patch glue inwetshwa kuphedi lebhodi lesifunda eliphrintiwe, lizobangela ukushisela okubi. Futhi ukuwa kwe-adhesive ye-patch yalezo zingxenye ezinezikhonkwane eziphakeme kakhulu, ayithinti umzimba oyinhloko wengxenye, okuzobangela ukunamathela okwanele, ngakho-ke izinga lokuwa kwe-adhesive ye-patch okulula ukugoqa kunzima ukubikezela, ngakho-ke ukusetha kokuqala kwenani le-coating yechashazi nakho kunzima. Ngenxa yalokhu, kufanele sikhethe lezo okungelula ukudilika kuzo, okungukuthi, isiqeshana esinesixazululo esikhulu kakhulu sokunyakaziswa. Ngokuwa okubangelwa ukubeka isikhathi eside kakhulu ngemuva kokumbozwa kwendawo, singasebenzisa isikhathi esifushane emva kokumbozwa kwendawo ukuqedela i-patch glue, ukuphulukisa ukugwema.

Ingxenye ye-offset

I-component offset yinto engathandeki eyenzeka kalula emishinini ye-SMT enesivinini esikhulu, futhi izizathu eziyinhloko yilezi:

I-1, ibhodi eliphrintiwe lokuhamba ngesivinini esiphezulu sokuqondisa kwe-XY okubangelwa i-offset, i-patch adhesive coating area yezingxenye ezincane ezithambekele kulo mkhuba, isizathu siwukuthi ukunamathela akubangelwa.

I-2, inani leglue ngaphansi kwezingxenye alihambisani (njengokuthi: amaphuzu amabili e-glue ngaphansi kwe-IC, iphuzu elilodwa leglue likhulu futhi iphuzu elilodwa leglue lincane), amandla eglue awalingani lapho eshiswa futhi ephulukiswa, futhi ukuphela nge-glue encane kulula ukuyisusa.

Izingxenye ze-wave soldering off

Izizathu ziyinkimbinkimbi:

1. Amandla okunamathela we-patch awanele.

2. Kube nomthelela ngaphambi kwe-wave soldering.

3. Kukhona izinsalela ezengeziwe kwezinye izingxenye.

4, i-colloid ayimelani nomthelela wokushisa okuphezulu

Hlanganisa i-glue mix

Abakhiqizi abahlukene be-patch glue ekubunjweni kwamakhemikhali banomehluko omkhulu, ukusetshenziswa okuxubile kulula ukukhiqiza okubi kakhulu: 1, ukuphulukisa ubunzima; 2, i-adhesive edluliselwe akwanele; 3, i-over wave soldering off serious.

Isixazululo siwukuthi: hlanza kahle ibhodi le-mesh, i-scraper, i-dispensive nezinye izingxenye okulula ukubangela ukuxuba, futhi ugweme ukuhlanganisa izinhlobo ezahlukene ze-patch glue.