Inqubo yokukhiqiza ye-PCBA enemininingwane (kuhlanganise nayo yonke inqubo ye-DIP), ngena futhi ubone!

"Inqubo ye-Wave Soldering"

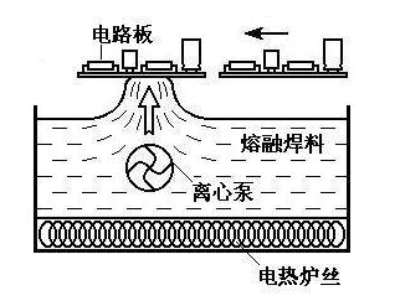

I-Wave soldering ngokuvamile iyinqubo yokushisela yamadivayisi e-plug-in. Kuyinqubo lapho i-solder yoketshezi encibilikisiwe, ngosizo lwepompo, yakha isimo esithile se-solder wave endaweni ewuketshezi yethangi le-solder, futhi i-PCB yengxenye efakiwe idlula endaweni ephakeme yegagasi le-solder nge-Engeli ethile kanye nokujula okuthile kokucwiliswa ochungechungeni lokudlulisa ukuze kuzuzwe ukushisela okuhlangene kwe-solder, njengoba kuboniswe esithombeni esingezansi.

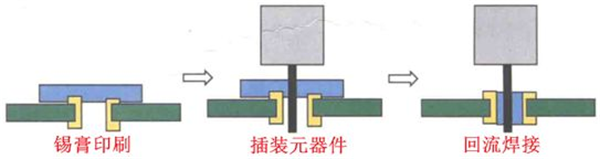

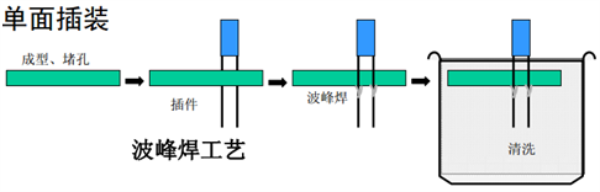

Ukugeleza kwenqubo evamile kungokulandelayo: ukufakwa kwedivayisi --PCB loading -- wave soldering --PCB unloading --DIP pin trimming -- ukuhlanza, njengoba kuboniswe emfanekisweni ongezansi.

1.THC ubuchwepheshe bokufaka

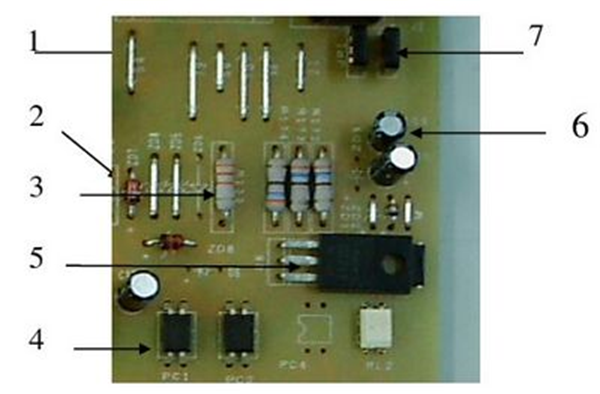

1. Ukwakhiwa kwephinikhodi yengxenye

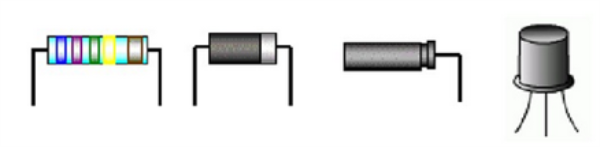

Amadivayisi e-DIP adinga ukulolongwa ngaphambi kokufakwa

(1)Ukubunjwa kwengxenye ecutshungulwe ngesandla: Iphinikhodi egobile ingalolongwa ngama-tweezers noma i-screwdriver encane, njengoba kuboniswe emfanekisweni ongezansi.

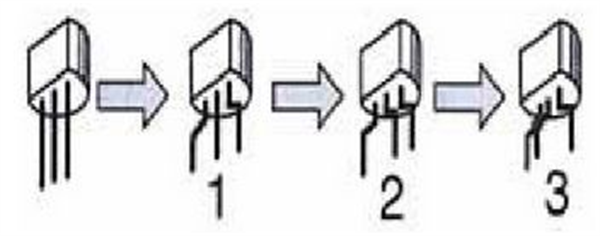

(2) Ukucutshungulwa komshini kwezingxenye ezibunjwayo: ukubunjwa komshini kwezingxenye kuqediwe ngomshini okhethekile wokubunjwa, isimiso sawo sokusebenza ukuthi isiphakeli sisebenzisa ukudlidliza kokuphakela izinto ezisetshenziswayo, (njenge-plug-in transistor) nesihlukanisi ukuze kutholwe i-transistor, isinyathelo sokuqala ukugoba izikhonkwane ezinhlangothini zombili kwesokunxele nakwesokudla; Isinyathelo sesibili ukugoba iphinikhodi ephakathi emuva noma uyidlulisele efomini. Njengoba kukhonjisiwe esithombeni esilandelayo.

2. Faka izingxenye

Ngokusebenzisa ubuchwepheshe bokufaka imbobo buhlukaniswe ngokufaka ngesandla kanye nokufakwa kwemishini ezenzakalelayo

(1) Ukufaka ngesandla ngesandla kanye nokushisela kufanele kuqala kufake lezo zingxenye ezidinga ukulungiswa ngomshini, njengezinsimbi zokupholisa, ubakaki, isiqeshana, njll., zomshini kagesi, bese ufaka izingxenye ezidinga ukushiselwa futhi zilungiswe. Ungazithinti izikhonkwane zengxenye necwecwe lethusi epuleti lokuphrinta ngokuqondile lapho ufaka.

(2) I-plug-in yemishini ezenzakalelayo (ebizwa ngokuthi i-AI) iwubuchwepheshe bokukhiqiza obuthuthuke kakhulu ekufakweni kwemikhiqizo ye-elekthronikhi yesimanje. Ukufakwa kwemishini ezenzakalelayo kufanele kuqala ifake lezo zingxenye ezinobude obuphansi, bese ifaka lezo zingxenye ezinobude obuphakeme. Izingxenye ezibalulekile ezibalulekile kufanele zifakwe ekufakweni kokugcina. Ukufakwa kwe-rack dissipation rack, ibakaki, isiqeshana, njll. kufanele kube seduze nenqubo yokushisela. Ukulandelana komhlangano wezingxenye ze-PCB kuboniswa esithombeni esilandelayo.

3. I-Wave soldering

(1) Umgomo wokusebenza we-wave soldering

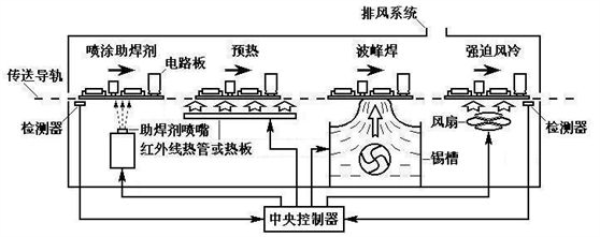

I-Wave soldering iwuhlobo lobuchwepheshe olwakha isimo esithile se-solder wave ebusweni be-solder encibilikisiwe yoketshezi ngokusebenzisa ingcindezi yokumpompa, futhi yakhe indawo yokudambisa endaweni yokushisela iphini lapho ingxenye yomhlangano efakwe nengxenye idlula i-solder wave nge-Angle engashintshi. Ingxenye iqala ukushisisa endaweni yokushisa yomshini wokushisela ngesikhathi senqubo yokudluliswa kwe-chain conveyor (ingxenye yokushisa ngaphambi kwesikhathi kanye nezinga lokushisa okufanele lifinyelelwe kusalawulwa yijika lokushisa elinqunywe kusengaphambili). Ekushiseleni kwangempela, ngokuvamile kuyadingeka ukulawula izinga lokushisa langaphambi kokushisa kwendawo engaphezulu, ngakho-ke amadivaysi amaningi angeze amadivaysi okuthola izinga lokushisa ahambisanayo (njengezitholi ze-infrared). Ngemuva kokushisa, umhlangano ungena emgodini oholayo we-welding. Ithangi likathayela liqukethe i-solder yoketshezi encibilikisiwe, futhi umlomo wombhobho ongaphansi kwethangi lensimbi ufafaza igagasi elimise okumile le-solder encibilikisiwe, ukuze kuthi lapho indawo yokushisela yengxenye idlula igagasi, ishisiswe yi-solder wave, futhi i-solder wave nayo imanzisa indawo yokushisela futhi inwebeke ukuze igcwalise, ekugcineni ifinyelele inqubo yokushisela. Umgomo wayo wokusebenza uboniswa esithombeni esingezansi.

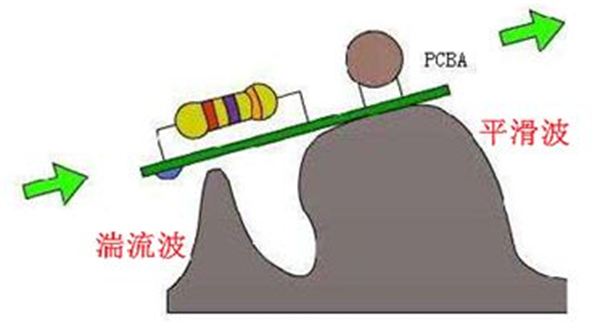

I-Wave soldering isebenzisa isimiso sokudlulisa ukushisa kwe-convection ukushisa indawo yokushisela. Igagasi elincibilikisiwe le-solder lisebenza njengomthombo wokushisa, ngakolunye uhlangothi ligeleza ukugeza indawo yokuthungatha iphinikhodi, ngakolunye uhlangothi futhi lidlala indima yokushisa ukushisa, futhi indawo yokufaka iphinikhodi iyashiswa ngaphansi kwalesi senzo. Ukuze kuqinisekiswe ukuthi indawo yokushisela iyashisa, i-wave ye-solder ngokuvamile inobubanzi obuthile, ukuze kuthi lapho i-welding surface yengxenye idlula igagasi, kukhona ukushisa okwanele, ukumanzisa, njalonjalo. Ku-wave soldering yendabuko, igagasi elilodwa livame ukusetshenziswa, futhi igagasi liyisicaba. Ngokusetshenziswa kwe-lead solder, okwamanje yamukelwa ngendlela ye-wave double. Njengoba kukhonjisiwe esithombeni esilandelayo.

Iphinikhodi yengxenye inikeza indlela yokuthi i-solder icwilise ku-metalized ngokusebenzisa imbobo esimweni esiqinile. Lapho iphini lithinta igagasi le-solder, i-solder ewuketshezi ikhwela phezu kwephini kanye nodonga lwembobo ngokucindezela phezulu. Isenzo se-capillary se-metalized ngokusebenzisa izimbobo sithuthukisa ukukhuphuka kwe-solder. Ngemuva kokuthi i-solder ifinyelele ku-pad ye-PcB, isakazeka ngaphansi kwesenzo sokucindezeleka okungaphezulu kwephedi. I-solder ekhuphukayo idonsa igesi egelezayo nomoya ovela emgodini, ngaleyo ndlela igcwalise imbobo bese yenza i-solder joint ngemva kokupholisa.

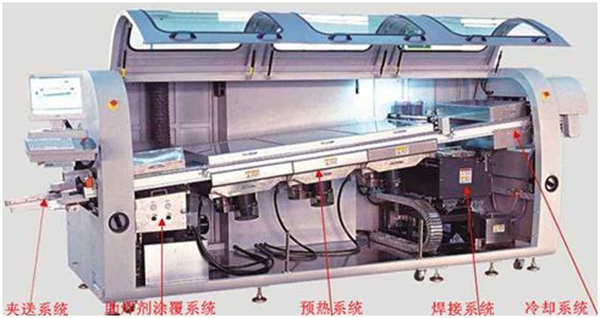

(2) Izingxenye eziyinhloko zomshini wokushisela igagasi

Umshini wokushisela amaza ngokuyinhloko wakhiwa ibhande lokuthutha, i-heater, ithangi likathayela, iphampu, kanye nedivaysi ephumayo namagwebu (noma isifutho). Ihlukaniswe ikakhulukazi indawo yokungeza i-flux, indawo yokushisa, indawo yokushisela kanye nendawo yokupholisa, njengoba kukhonjisiwe esithombeni esilandelayo.

3. Umehluko omkhulu phakathi kwe-wave soldering kanye ne-reflow welding

Umehluko omkhulu phakathi kwe-wave soldering kanye ne-reflow welding ukuthi umthombo wokushisa kanye nendlela yokuhlinzeka nge-solder ku-welding ihlukile. Ekufakweni kwe-wave soldering, i-solder ishisa ngaphambili futhi inyibilika ethangini, futhi i-solder wave ekhiqizwa yipompo idlala indima emibili yomthombo wokushisa kanye nokunikezwa kwe-solder. Igagasi elincibilikisiwe le-solder lishisisa izimbobo, amaphedi, nezikhonkwane zengxenye ye-PCB, kuyilapho linikeza i-solder edingekayo ukuze kwakhe amajoyinti e-solder. Ku-reflow soldering, i-solder (i-solder paste) inikezwa ngaphambilini endaweni yokushisela ye-PCB, futhi indima yomthombo wokushisa ngesikhathi sokugeleza kabusha ukuncibilikisa kabusha i-solder.

(1) 3 Isingeniso senqubo ekhethiwe yokuhlanganisa amaza

Imishini ye-Wave soldering iye yasungulwa iminyaka engaphezu kwengu-50, futhi inezinzuzo zokusebenza kahle kokukhiqiza okuphezulu kanye nokukhipha okukhulu ekukhiqizeni izingxenye zembobo namabhodi wesekethe, ngakho yayiyimishini yokushisela ebaluleke kakhulu ekukhiqizeni okuzenzakalelayo kwemikhiqizo ye-elekthronikhi. Kodwa-ke, kunemikhawulo ethile ekusetshenzisweni kwayo: (1) imingcele yokushisela ihlukile.

Amajoyinti ahlukene e-solder ebhodini lesifunda elifanayo angase adinge amapharamitha wokushisela ahluke kakhulu ngenxa yezimpawu zawo ezihlukene (njengomthamo wokushisa, isikhala sephini, izidingo zokungena kwe-tin, njll.). Kodwa-ke, isici se-wave soldering ukuqedela ukushiswa kwawo wonke amalunga e-solder ebhodini lesifunda lonke ngaphansi kwemingcele efanayo ebekiwe, ngakho-ke amalunga e-solder ahlukene adinga "ukuxazulula" nomunye nomunye, okwenza i-wave soldering ibe nzima nakakhulu ukuhlangabezana ngokugcwele nezidingo zokushisela zamabhodi wesifunda aphezulu;

(2) Izindleko eziphezulu zokusebenza.

Ekusetshenzisweni okungokoqobo kwe-wave soldering yendabuko, ukufuthwa kwamapuleti okugeleza kanye nokukhiqizwa kwe-tin slag kuletha izindleko eziphezulu zokusebenza. Ikakhulukazi lapho i-welding-free welding, ngoba intengo ye-solder-free solder ingaphezu kwezikhathi ezingu-3 kune-lead solder, ukwanda kwezindleko zokusebenza okubangelwa i-tin slag kuyamangalisa kakhulu. Ngaphezu kwalokho, i-solder engenawo umthofu iyaqhubeka nokuncibilikisa ithusi ku-pad, futhi ukwakheka kwe-solder ku-cylinder ye-tin kuzoshintsha ngokuhamba kwesikhathi, okudinga ukungezwa okujwayelekile kwe-tin ehlanzekile nesiliva elibizayo ukuxazulula;

(3) Inkinga yesondlo nesondlo.

I-flux eyinsalela ekukhiqizeni izohlala ohlelweni lokudluliswa kwe-wave soldering, futhi i-tin slag ekhiqizwayo idinga ukususwa njalo, okuletha umsebenzi onzima kakhulu wokugcinwa nokugcinwa kwemishini kumsebenzisi; Ngenxa yezizathu ezinjalo, i-wave soldering ekhethiwe yaba khona.

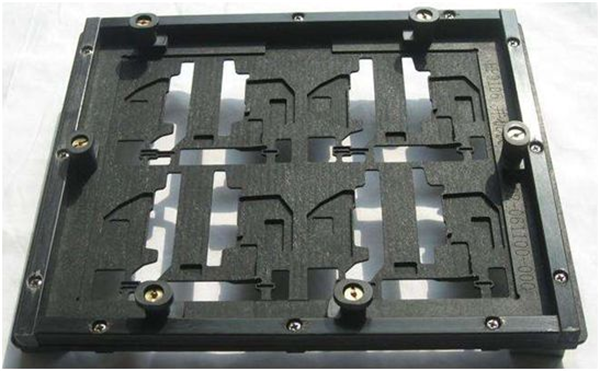

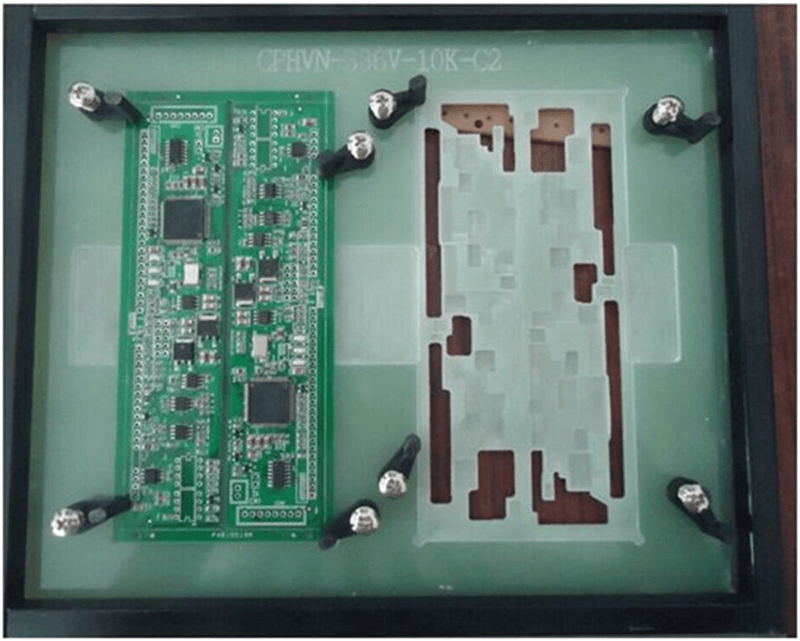

Okubizwa ngokuthi i-PCBA selective wave soldering zisasebenzisa isithando somlilo sokuqala, kodwa umehluko wukuthi ibhodi lidinga ukufakwa esiphathini somlilo wethayela, okuyilokho esivame ukukusho mayelana nokulungiswa kwesithando somlilo, njengoba kuboniswe esithombeni esingezansi.

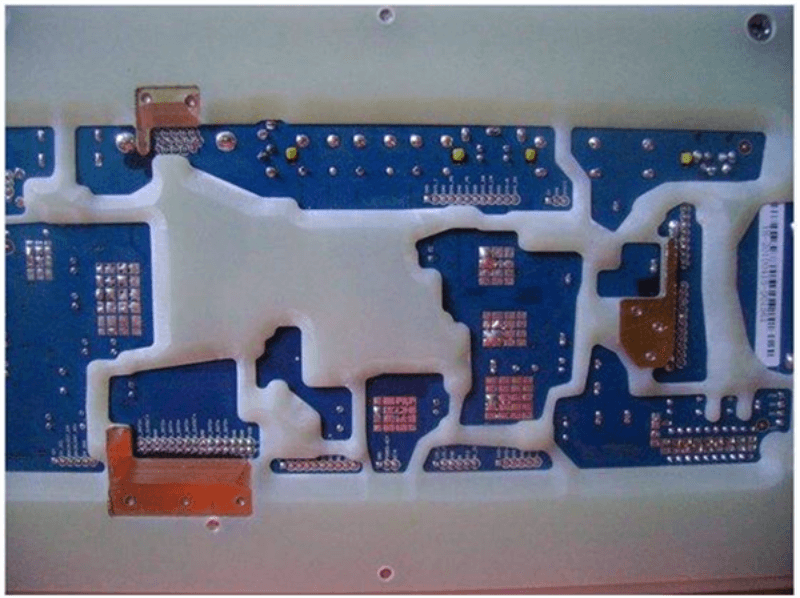

Izingxenye ezidinga i-wave soldering zibe sezivezwa ethini, kanti ezinye izingxenye zivikelwe ngokuvala imoto, njengoba kuboniswe ngezansi. Lokhu kufana nokufaka i-life buoy ku-swimming pool, indawo embozwe i-life buoy ngeke iwathole amanzi, esikhundleni salokho kufakwe isitofu sikathayela, indawo evalwe yimoto ngokwemvelo ngeke ithole uthayela, futhi ngeke ibe khona inkinga yokuphinda kuncibilike ithini noma izingxenye eziwayo.

"Ngenqubo ye-Hole Reflow Welding"

I-In-hole reflow welding iyinqubo ye-reflow welding yokufaka izingxenye, esetshenziswa kakhulu ekwenzeni amapuleti okuhlanganisa angaphezulu aqukethe ama-plug-in ambalwa. Umnyombo wobuchwepheshe yindlela yokufaka i-solder paste.

1. Isingeniso senqubo

Ngokwendlela yokufaka isicelo sokunamathisela i-solder, nge-hole reflow welding ingahlukaniswa ngezinhlobo ezintathu: ukuphrinta kwepayipi ngokusebenzisa inqubo ye-hole reflow welding, ukuphrinta kwe-solder paste ngenqubo ye-hole reflow welding kanye neshidi elibunjiwe le-tin ngokusebenzisa inqubo ye-hole reflow welding.

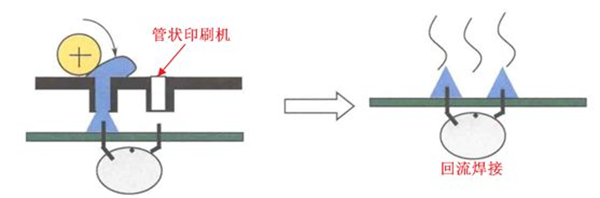

1) Ukuphrinta kwe-Tubular ngokusebenzisa inqubo ye-hole reflow welding

Ukuphrinta kwe-tubular ngenqubo ye-hole reflow welding kuwuhlelo lokuqala lokusebenza lwenqubo yokushisela yezingxenye zembobo, esetshenziswa kakhulu ekwenzeni ishuna ye-TV enemibala. Umnyombo wenqubo yi-solder unamathisele umshini wokucindezela we-tubular, inqubo iboniswa esithombeni esingezansi.

2) Solder unama ukuphrinta ngokusebenzisa imbobo reflow Welding inqubo

Ukuphrinta kokunamathisela kwe-Solder ngenqubo ye-hole reflow welding okwamanje iyona esetshenziswa kakhulu ngenqubo ye-hole reflow welding, ikakhulukazi esetshenziselwa i-PCBA exubekile equkethe inani elincane lama-plug-ins, inqubo ihambisana ngokugcwele nenqubo ye-reflow welding evamile, akukho mishini yenqubo ekhethekile edingekayo, okuwukuphela kwemfuneko ukuthi izingxenye ze-plug-in ezishiselwe kufanele zifaneleke ngokusebenzisa inqubo ye-hole reflow eboniswayo.

3) Ukubumba tin sheet ngokusebenzisa imbobo reflow Welding inqubo

Ishidi elibunjiwe likathayela ngenqubo ye-hole reflow welding lisetshenziselwa ikakhulukazi izixhumi ezinamaphini amaningi, i-solder ayiyona i-solder paste kodwa ishidi elibunjiwe likathayela, ngokuvamile ngumkhiqizi wesixhumi wengezwe ngokuqondile, umhlangano ungashiswa kuphela.

Ngokusebenzisa izidingo zokuklama ukugeleza kabusha kwembobo

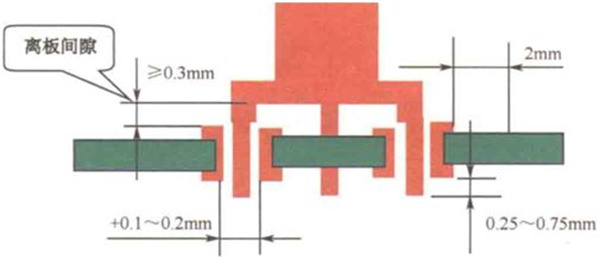

1.PCB design izidingo

(1) Ifanele ukujiya kwe-PCB okungaphansi noma okulingana nebhodi elingu-1.6mm.

(2) Ububanzi obuncane bephedi bungu-0.25mm, futhi inhlama ye-solder encibilikisiwe "idonswa" kanye, futhi ubuhlalu bethini abukhiwe.

(3) Igebe lengxenye engaphandle kwebhodi (Ukumiswa) kufanele libe likhulu kuno-0.3mm

(4) Ubude obufanele bomthofu ophumela ngaphandle kwephedi buyi-0.25~0.75mm.

(5) Ibanga elincane phakathi kwezingxenye zokuhlukanisa izikhala ezifana no-0603 kanye nephedi ngu-2mm.

(6) Ukuvulwa okuphezulu kwe-mesh yensimbi kunganwetshwa ngo-1.5mm.

(7)Imbobo ingububanzi bomthofu kanye no-0.1~0.2mm. Njengoba kukhonjisiwe esithombeni esilandelayo.

"Izimfuneko zokuvula iwindi lemeshi yensimbi"

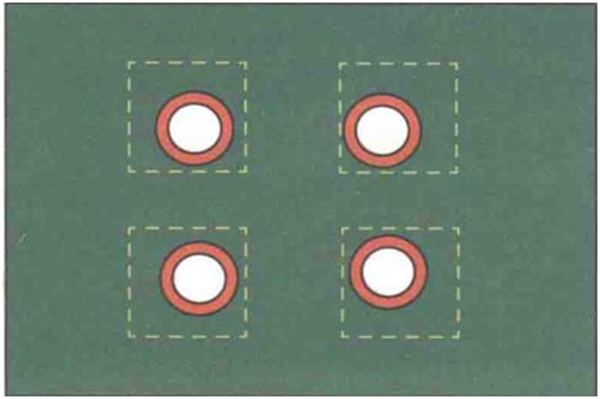

Ngokuvamile, ukuze kuzuzwe ukugcwaliswa kwemigodi engu-50%, iwindi lensimbi yensimbi kufanele linwetshwe, inani elithile lokunwetshwa kwangaphandle kufanele linqunywe ngokusho kobukhulu be-PCB, ubukhulu bensimbi yensimbi, igebe phakathi kwembobo nokuhola nezinye izici.

Ngokuvamile, inqobo nje uma ukunwetshwa kungadluli ku-2mm, ukunamathisela kwe-solder kuzodonselwa emuva futhi kugcwaliswe emgodini. Kumele kuqashelwe ukuthi ukunwetshwa kwangaphandle akukwazi ukucindezelwa yiphakheji yengxenye, noma kufanele kugweme umzimba wephakheji wengxenye, futhi kwakha ubuhlalu bethini ngakolunye uhlangothi, njengoba kuboniswe esithombeni esilandelayo.

"Isingeniso Senqubo Yomhlangano Ovamile we-PCBA"

1) Ukukhweza ohlangothini olulodwa

Ukugeleza kwenqubo kuboniswa esithombeni esingezansi

2) Ukufakwa ohlangothini olulodwa

Ukugeleza kwenqubo kuboniswe kuMfanekiso 5 ngezansi

Ukwakhiwa kwezikhonkwane zedivayisi ekufakweni kwe-wave soldering kungenye yezingxenye ezisebenza kancane zenqubo yokukhiqiza, okuletha ngokufanayo ubungozi bokulimala kwe-electrostatic futhi kwandise isikhathi sokulethwa, futhi kwandisa nethuba lephutha.

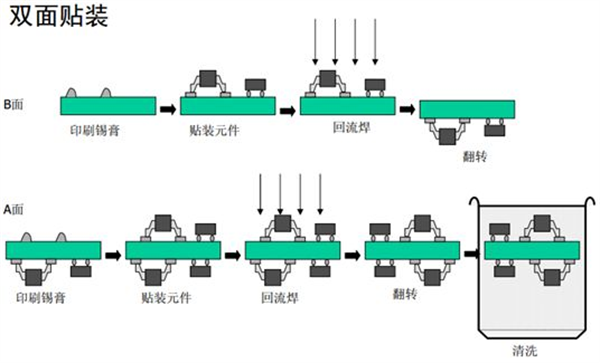

3) Ukukhweza okunezinhlangothi ezimbili

Ukugeleza kwenqubo kuboniswa esithombeni esingezansi

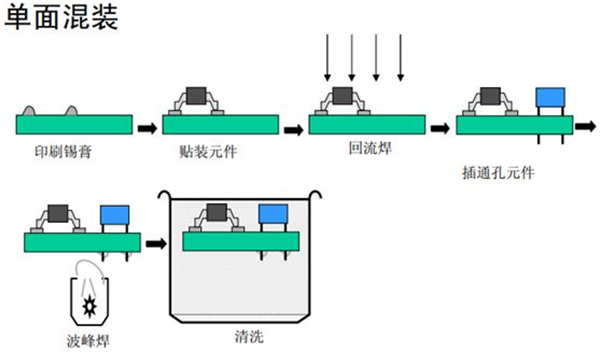

4) Uhlangothi olulodwa luxubile

Ukugeleza kwenqubo kuboniswa esithombeni esingezansi

Uma kunezingxenye ezimbalwa ze- through-hole, i-reflow welding kanye ne-manual welding ingasetshenziswa.

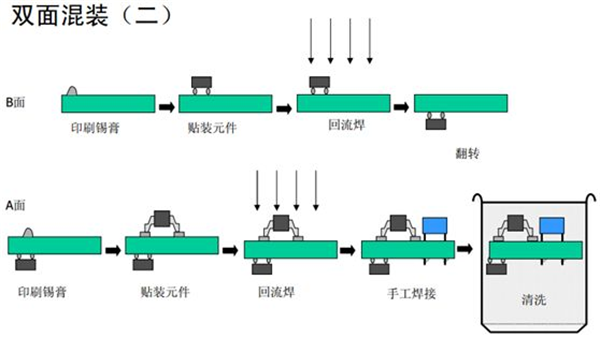

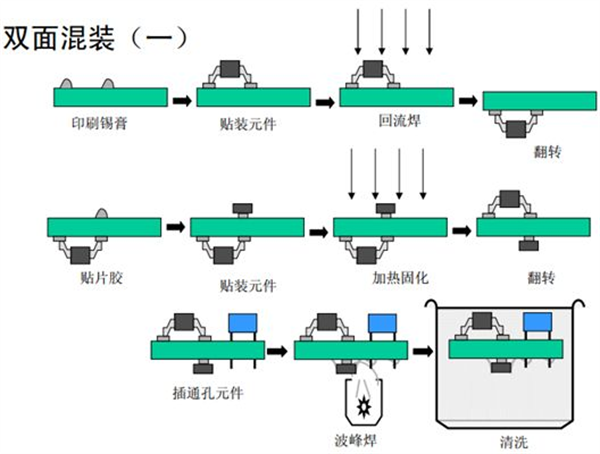

5) Ukuxuba okuphindwe kabili

Ukugeleza kwenqubo kuboniswa esithombeni esingezansi

Uma kukhona amadivaysi e-SMD anezinhlangothi ezimbili ezengeziwe kanye nezingxenye ezimbalwa ze-THT, amadivaysi e-plug-in angase ageleze kabusha noma ashiselwe ngesandla. Ishadi lokugeleza kwenqubo liboniswa ngezansi.